Despite unicycles having far fewer kit choices, this is literally me over every single detail of this build ![]()

![]() :

:

The advantage of this rim is its extreme lightness (250g). If you think it’s better to have a reinforced rim, it may be better to opt for a more standard rim, as you’ll have more choice when it comes to rim width.

Personally, I’ve used this rim with a 2“ tire and a 2.25” tire with no problem. For me, the main disadvantage of a rim that’s too narrow is a blow out. To reduce this risk, using an inner tube is a good start. This reminds me that I need to install a TPU inner tube on this wheel.

I’d definitely stick with 36H, especially with that wider bearing spacing. As for the frame, I’ve heard the Mad4One needs a little tweaking to fit perfectly, but it’s worth it for the looks, haha.

Just a little update on the build process. The wheel has finally been built! It took nearly 2 months for Light Bicycles to ship the AR25 rim.

Pretty much all I need are the frame, tire, and aero bar setup, after which I’ll purchase the bags for unitouring.

I finally got to install the tire and cranks today!

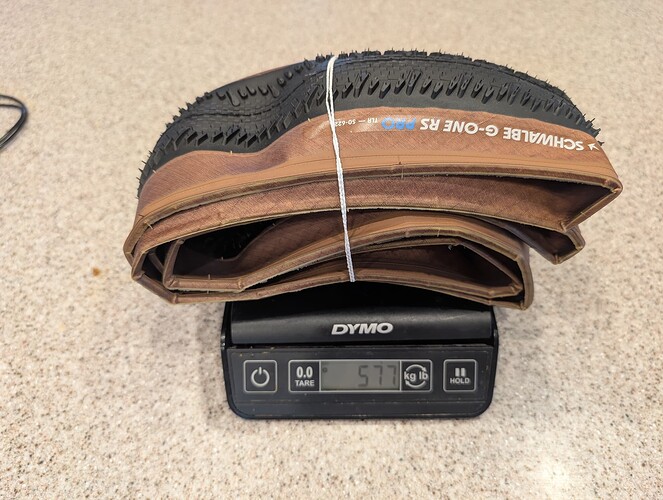

The tire I went with is a Schwalbe G-One RS Pro 28"x2.00 (50-622). I planned to go with a Schwalbe Thunder Burt 29"x2.1" since I was particularly impressed by it’s rolling resistance score on BicycleRollingResistance.com and from Aurélien’s recommendation that it tracks straight. However, it’s out of stock except for BikeInn, which I have had negative experiences with before. I’ve been dying to ride this thing so I said, “Hell, why not? Let’s get this other Schwalbe tire!” It, too, has an impressive rolling resistance score. Although on paper it’s not quite as wide as I’d like

I also installed the cranks today (something I could’ve done sooner but felt no need to do without a tire). I’m trying a pair of VCX+ 150/125/100s. Not sure if I’ll stick with it, as 137/117 sounds like a good middle ground.

The only sticking point I have is whether the cranks should be pressing against the spacers. I tightened them to 50 Nm (I didn’t dare push to the max recommended 55 Nm for fear of rounding out the bolts) yet there’s still a little gap and they rattle around. Is this just a result of using non-KH cranks?

Tomorrow I’ll meet up with a friend to try it out with his Schlumpf compatible frame. Can’t wait!

Nice build !

Are the silver triangles light reflectors? And if yes, are they strongly attached to the spoke and resistant?

I have had a good experience with the 3M clip-on reflective tubes (my description not their official name) but I lost some of them over time. These look smaller but could be good if they are clinging for dear life and not too expensive to get ![]()

They are RydeSafe reflective spoke stickers. Super lightweight, although a bit pricey even though they’re on sale now.

They don’t hold on too well by themselves but I secured them with a bit of transparent tape on the neighboring spoke. Time will tell how well they hold up!

Mine are the same. There is a bit of space between the spacer and the cranks. Using Nimbus Venture 2 cranks. I think you will have the same gap with KH cranks but can’t remember if I read about anyone sharing the outcome. You can head over to Schlumpf 2022 Build Questions for more info and you might find it in the really long thread ![]()

“The only sticking point I have is whether the cranks should be pressing against the spacers. I tightened them to 50 Nm (I didn’t dare push to the max recommended 55 Nm for fear of rounding out the bolts) yet there’s still a little gap and they rattle around. Is this just a result of using non-KH cranks?” --Isis interface stipulates no gap–the crank should be tight against the spacer. If it’s not you need a wider spacer. I haven’t any experience with Schlumpf hubs so I might be talking out of turn but I’ve learned from experience that most uni cranks work best with 6mm spacers outside the bearing and 5mm(?) inside the bearing. The old Venture 2 cranks required 7mm outside spacers. I made the mistake of thinking that KH cranks required 5mm spacers but thru experience figured out that 6mm is best (w/ no outboard disc clearance issues). So just to sum up: the Isis standard requires that the crank be tightened hard against the spacer. If it’s not and there’s a gap the bearing will move around creaking like mad and the cranks will lose their tolerances as they will only be as tight as the old square taper standard…

I have KH cranks on my Schlumpf and yes, it’s the same. I had to remove them, add additional spacers, and then re-install the cranks.

I think old Schlumpf hubs didn’t have spacers installed as they would push against the bearings. But the most recent iteration (maybe already earlier models, I’m no expert) has a groove in the axis and a ring that sits in the groove. The spacer then pushes against a sort of washer which in turn pushes against said ring.

Advantages of using a correct width spacer: crank unlikely to loosen up by itself, the cranks’ ISIS interface will not widen, the loose spacer will not ring while you ride the uni. And after using spacers of the correct width I stayed at the lower end of the recommended torque range to protect the (way too soft) crank bolts. So far no issues.

And after using spacers of the correct width I stayed at the lower end of the recommended torque range to protect the (way too soft) crank bolts. So far no issues.

I agree, the crank bolts are far too soft. I rounded out a bolt tightening it to 45Nm with a torque wrench. Took it to my LBS and they removed it in a jiffy using an oversized Torch wrench and some light tapping of a hammer.

They really should be made of hardened steel (I’m assuming they’re aluminum). Especially since Florian supplies a hardened steel hex bit, it only makes sense IMO.

I had to remove them, add additional spacers, and then re-install the cranks.

I’ll be sure to do that as soon as I can. Although, I’m really itching to go on a long ride ASAP, so that can wait ![]()

Additional problem with the bolts is, they are an uncommon thread diameter (14mm if I’m not mistaken), so you can’t just take an ordinary bolt and drill a hole. Well, I did, but that didn’t help any when I tried to install it ![]() . I found bolts of the correct size on ebay, but they’re a bit short. Still, when I have to remove the cranks and re-install them or install different ones, I will use the other bolts, tighten them to the indicated torque, and then replace them by Florian’s bolts. That should prolong their lives somewhat.

. I found bolts of the correct size on ebay, but they’re a bit short. Still, when I have to remove the cranks and re-install them or install different ones, I will use the other bolts, tighten them to the indicated torque, and then replace them by Florian’s bolts. That should prolong their lives somewhat.

By the way, I’m pretty sure they are stainless steel. Just not hard enough.

Would you mind sharing a link to those bolts if you still have it?

Here you go: Crank bolts M14x100 bike arm screw bottom bracket crankset quality part steel | eBay

Caveat: I haven’t used them yet, since I had no reason to remove and re-install the cranks, yet. But I think @mindbalance has used the same. Maybe he can chime in.

All should be covered here - https://youtu.be/50_xrEmnpoI - but if not ask any questions

15 posts were split to a new topic: Alternative brake rotors for Schlumpf gen. 5

Maybe we should move this discussion to another topic as this is no more related to the G29 P-Frame build.

Yes, thank you! Haha I was going to mention that.

To give a small update on my build, this is what I have so far:

I’m using the frame from my KH27.5 for now. It’s adequate for everyday rides but certainly not touring ready like a P-Frame. Still hashing out the details on that with @jaco_flans.

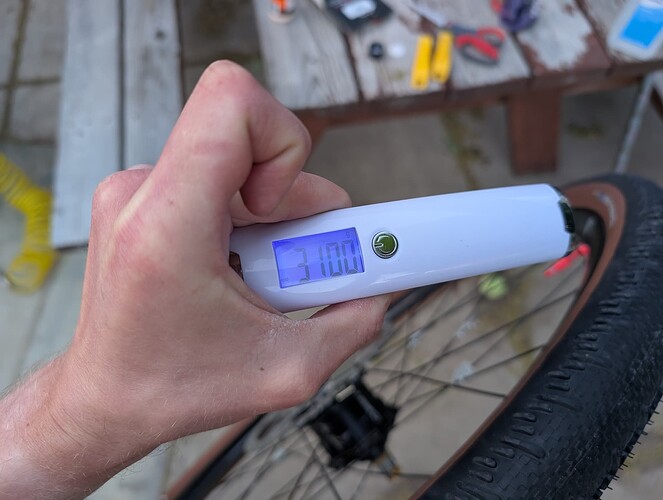

I also installed a Schwalbe Thunder Burt 29"x2.1" Super Ground. Absolutely love it. Thank you, @Aurelien for the recommendation. I set it up to be tubeless and so far so good. It rolls really straight but is still nimble enough to dodge obstacles and light enough to climb hills. (In fact, I measured both and it’s 6 grams lighter than the Schwalbe G-One RS Pro 700c x 50mm that I installed earlier).

Also, I’m borrowing an Ursuli handle from @Elias and it’s significantly more comfortable than the M4O (short) handle I was using at first.

Next steps are to install a new brake kit after my warranty-covered rotor replacements arrive. I’ve been cannibalizing the brake kit from my KH27.5.

Re: Spacers on a Schlumpf hub.

I read through bits and pieces of the Schlumpf 2022 Build Questions thread and now I’m more confused than before.

Should I put additional spacers on top of the existing spacer or not? Or are there spacers I can buy that precisely fit? Or no spacers at all?

In that thread there was a lot of “I did what so-and-so recommended” without saying what the recommendation even was, so I got very confused.

I’m swapping cranks to 138mm soon so I thought then would be the perfect time to solve my rattling spacers issue.

In my experience, spacers are pure luck. Their required thickness heavily depends on the cranks they are combined with. When you tighten any ISIS crank you need to apply gradually more torque before the crank hits the spacer. That’s due to the slightly conical engagement with the ISIS interface.

I have 3 pairs of Venture cranks (125, 150, 165mm). They all need thinner spacers than other makes. One set couldn’t even be used on a given hub because it was too loose: the cranks simply wouldn’t have a firm fit on the axle, even when I dropped the spacer completely! So I had to use my QUAX cranks of the same length (but silver instead of black) and they fit just fine…

Bottom line: spacers are pure luck (did I mention that before?) and it’s good to have several sets of different thickness to try. Or to have access to a lathe in order to adapt them as needed.