Hello everyone ![]()

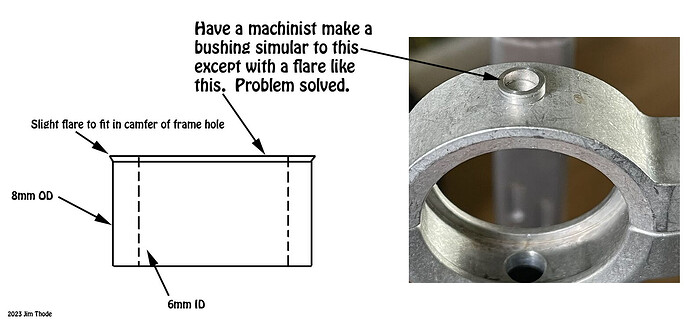

Does any one here have a good simple idea on how I can secure this small shim into the 8mm holes drilled into my Flansberrium frames?

I will also ask for @jaco_flans input, given that he’d likely have a clear understanding on if a glue would be viable / safe to use.

The shims fit perfectly but as there is a void below into the fork legs, there’s a risk that it could just fall or be pushed right the way through and be lost forever, rattling around.

I am thinking that holding the shim on a small wooden dowel or pencil end, and then applying an epoxy glue to its edge and the inside edge of the hole, might work.

I’d then aim to push the shim into place upwards, with gravity helping ensure it doesn’t go into the void.

It doesn’t need to be massively strong. Just don’t want it to get lost or end up being pushed in should I ever take the wheel out of the frame and then reinstall it.

Looking at the shim, I’m also now convinced this is needed as I’d not be comfortable running the hubs with their 6mm blocking nub, in an 8mm hole ![]()

I even wondered if there was some kind of expanding foam or substance I could use to block up the void so that the shim was going into a firm/blocked surface.

Well, any ideas welcome ![]() Thanks

Thanks