Probably. If you can’t see blood or injuries, don’t click the following link. (Some of you might already have the picture of the injury of @udiron in their head by just looking at the rotor above.)

203mm would be my preference.

Regarding thickness; I would agree to go for the larger one if that indeed improves the integrity or manufacturability noticeably. But I was quickly checking the specs of the brake I now have mounted (Magura MT5), and that one is specified for 1.8 to 2.0mm.

I checked several disc brakes from Shimano, and on their site I can’t find a thickness spec whats so ever.

Personally I would not mind ‘that’ much buying another disc brake (my 36" already needs a new one, so then I’ll just transfer this one ![]() ), but I can’t quickly find a disc brake specified for 2.3mm.

), but I can’t quickly find a disc brake specified for 2.3mm.

Yes indeed, I did see that recently and it made we wonder a bit about my one. I tried to convince myself that it isn’t quite as sharp though, the one in the link wouldn’t look out of place on a table saw. That said, having it on an outboard brake maybe isn’t the best idea.

I am usually more concerned about the pins on the pedals to be honest – they are quite ‘aggressive’ to say the least. I have ripped the back of my leg up quite badly in the past with Nimbus pedal pins and they are quite tame compared to those Hope ones.

Every single time I see such a stupid brake disk.

Disk_4.stp (443.7 KB)

- Changed to 9 spokes

- Adapted outer pattern to fit 9 spoke design

- added 0.1 mm clearance to the hub fit

I’d say that this is a good shot now. Can’t guarantee obviously, but it is closely following known good designs, which well… can’t be said for the original.

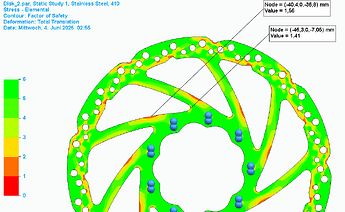

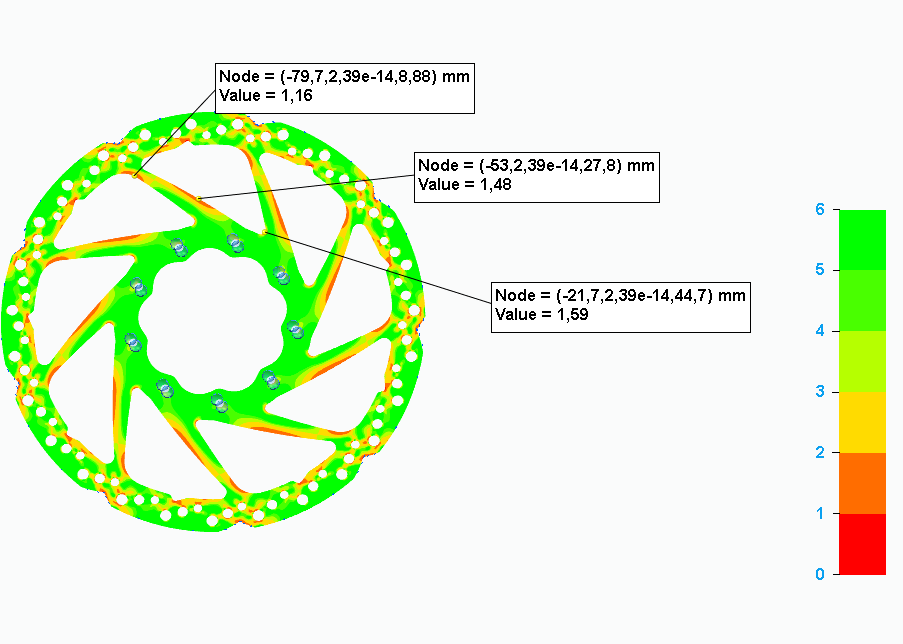

Silly quick FEM says 395 N m (120 kg on a 36" decelerating at 0.8G, very very unlikely) is fine. (v.Mises vs. yield strength of 410 stainless steel)

Minimum safety factor of 1.4 with such an extreme scenario should be fine. Ignore the seemingly high stress concentration on the outer ring, the way I applied the torque is on the outer edge, not very accurate.

We asked the factory about this some time ago and they said due to their design their brakes are progressive so have a larger clearance than the most on the market. Yes, no figures! but it implies it is ok. I will ask some more questions specifically about this.

Fantastic, thank you.

Does your FEM package allow analysis of thermal expansion? This I think is potentially our biggest problem. Do spokes of this size allow them to bend/flex with the expansion without distorting the brake surface?

It is interesting to see the stress raiser at the inner notch, I know that is small and not a problem, but higher than I thought it would be.

If you made the spokes tapered slightly, would it reduce the stress raiser at the their base? or would this potentially make the design too stiff?

Some research says that the majority of disc callipers post 2019 are compatible with 2.3 disc’s. There are few exceptions like, Hope’s V2 or Trial‐series callipers and Hayes Dominion A-series.

Tried a more agressive taper, no big improvement.

I strongly suspect the stress riser at the inner notch to be from the way I set boundary conditions, with the torque properly applied at the whole braking surface there should be less torsion through that part and less localized stresses. (I’ll try to figure out how to set the BCs better).

Maybe I’ll play around with it some more. I’m using the inbuilt FEM in SolidEdge. I’m too spoiled with the full Ansys suite at work and while SolidEdge offers some options for combined thermal and static structural it seems very limited when it comes to precisely applying boundary conditions where I’d want them.

Maybe more importantly, when I say “playing around” I mean it, without further validation I would not trust any results of a relatively complex analysis like that. Sure I can generate some pretty pictures, but if they correspond to reality in any way would be questionable, depends too much on the assumptions for heat transfer into environment and hub I would suspect. (And a full parameter sensitivity analysis to get insight without validation is well out of scope for the time I have for side projects.)

As an engineering prof once told us: “Step one of development: Benchmark the existing products and find their problems.” Warped brake surfaces don’t seem like a big problem with disk with directional spokes, so I don’t expect one here.

Vast majority of brakes used on unicycles seems to be shimano and hope, so personally I would think 2.3 would be fine and potentially offers a longer disk lifetime. Wouldn’t it at worst be a job of sanding 0.25 mm of new brake pads to make a brake compatible?

Any updates on this project? Hope (no pun intended) everything works out with Hope!

From my side I would leave the design as is and I will leave it to and @maxence @rogeratunicycledotcom to discuss the further steps with Hope.

Ultimately it’s a question of price I would guess, I know Timo designed an adapter from the new Schlumpf to Shimano 203 Icetec outer disks (similar idea to brakefast) that he got CNC machined for 50€. Also an option if the plan with hope doesn’t work out, although then again it’s a case of finding someone to take the upfront cost and handle the logistics..(plus I don’t like the limited amount of future proofness of relying on Shimano not changing their disk design..)

I think we are happy to move forward, who is wanting them? Ideally we need >10 to go ahead with the order. No commitment at this stage, but this will give me a clue as what to order and will get a quote so I can give you the price before actually placing the order. (I have put 180 on the pole, but I know from the discussion this may not be wanted).

- 180 Schlumpf hub >M1200 rotor from Hope

- 203 Schlumpf hub >M1200 rotor from Hope

Any more interested in one of these rotors?

Let me share this on the French forum. There may be a few more people there.

Just to reiterate, I’m interested in purchasing 2 of them, ideally 203mm in 2.3mm thickness. Maybe more than 2 if the price is right.

If you need to get the numbers up to make it viable I’ll take one (assuming reasonable price) – I don’t have a Schlumpf at the moment but may get one down the line.

Are we ok to order? By the look on the figures it will be 203 x 2.3mm that is ordered. I will order enough for those who have expressed interest and a few more.

Are you ok with the design?

OK with the design.

BTW, someone has expressed their interest on the French forum weeks ago. They didn’t replied to my last post, but they don’t seem to have been active for this period. Could you please add 1x rotor for them?

I’d like to get 2 rotors for myself as well ![]()

Thanks for your work!

[EDIT] Adrien - the person that has been inactive for the last week - has confirmed his order. He’d like a rotor ![]()

Any hints to the final price? Or does it depend on the numbers ordered?

I’m okay to order two of them. How will final payment and shipment occur? Will it be listed on UDC UK?