Thanks Felix.

I am contemplating buying a schlumpf hub, I figure it would be good for going fast and far in nice flat areas, at the moment I’m limited by pedalling speed. The hub is approx AUD$2500 though… I don’t have any aluminium framed unis, only steel.

Time to buy a new frame then! Such a great hub should not be put into a low-end frame ![]()

Hi Didier - the hole is only needed on the the left side.

Low end frames? Steel frames currently on the market are, but it’s not because it’s steel that it’s low-end! I freshly finished a 36er frame made with 4130 steel, and already compatible with all the ISIS schlumpfs generations ![]() . Yes there is a little weight penalty over an alloy frame, but it will be a lot stiffer. Plus it’s made with aero tubing, so hey, it should be faster right?

. Yes there is a little weight penalty over an alloy frame, but it will be a lot stiffer. Plus it’s made with aero tubing, so hey, it should be faster right? ![]()

It might be interesting to see old school steel bicycle style steel frames with intricate lugs. Some of those were beautiful and a unicycle made in that style would be really cool.

Nimbus and a bunch of other brands used to make frames like that. Currently I think Miyata might be the only one still making this type of frame: https://unicycle.onlinestores.jp/resources/upload/products/FL2021.jpg

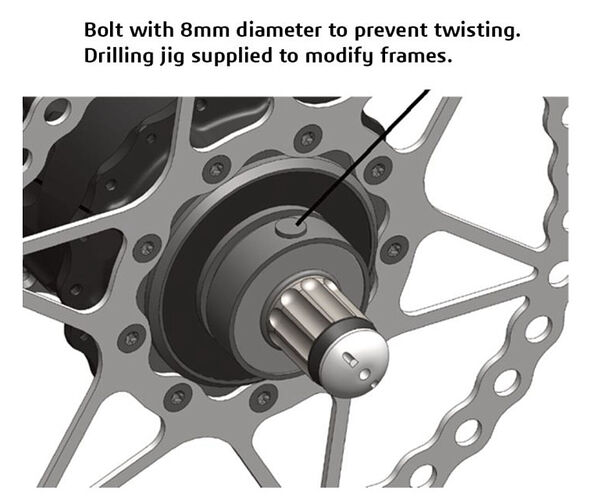

Hey all - update on the comment above, regarding 6 mm vs 8 mm hole for the lock.

It is going to be 8 mm after all - sunwheel production moved faster than expected.

Re KH frame modification (can’t comment on others) - suggest avoiding drilling out the upper bearing housing to avoid potential for affecting the weld join.

Yes, the steel 42mm bearing clamps would/do work really with Schlumpf hubs. I used one for my Lands End to John O’Groats ride.

I’m confused by the 8mm drilling thing - where does the hole need to go and why?

It’ll go into the top section of the bearing mounts. So frame legs side. If frame doesn’t have the hole then the jig will line up a spot for you to drill it.

It’s purpose is to hold that bearing so that it cannot rotate as the hub needs a torque reaction fastener to function.

Previous the solution was a little notch, before that knurling on the bearing for a compression friction fit hold, and way way way before that there was a torque arm that came out of the hub’s body and bolted to the frame.

Hope this helps a bit! ![]()

![]()

Could we have a poll on Aluminium frame vs Steel frame?

Our just some reply’s to help me decide.

I’m chatting with Jaco_flans to order a frame for a 125mm schlumpf hub.

I intend to continue commuting 3 days a week with it. It is a hilly commute 15km 150m elevation gain, a couple of biggish hills 25m elev gain at 8-12% grade that I like climbing on current KH36 with 127mm cranks. I am wondering if frame flex and wheel rub would be a problem with aluminium frame and schlumpf hub.

I recently experienced wheel rub on my KH29 127mm crank hill climbing the Access road to Remarkables ski field. Ave 9.5% grade. Tyre press. 42psi.

So, for me would the stiffness of steel be worth the extra weight for hill climbing? I am 74kg. Was 78kg.

Or

Is the weight saving worth the Aluminium frame with a 1.8kg 125mm schlumpf hub….and frame flex is not an issue or can be managed by other ways, like less tire pressure.

BTW, I only recently became comfortable maintaining 22kph on roads with slight downhill ( in the centre of lane with no traffic behind) using radar on rear light notifying me of any traffic. I wear a 5kg backpack with work computer and lunch..

…will go the full body armour and full face helmet with the schlumpf…but what speeds can I expect in same situation with a schlumpf?

- Steel Frame 36” Schlumpf

- Aluminium Frame 36” Schlumpf

I’d be interested to see the results to this.

My gut says most go with aluminium and it is fine. But I have thought about a Flansberrium frame in steel if I was going to the trouble of having him build me one for a 125mm hub.

Having said that I might also check out if Triton are going to be able to make unicycle frames again (now they’ve moved to Portugal).

Might be a longer wait but I think they’d be stiffer and also lighter too (if my understanding of metals - titanium v steel - is on the money)

Slight change of subject, I wasn’t away of tyre pressure being a cause of frame flex, learn something new everyday. Anyone got any feedback on that? Not that I ever noticed flex on my KH29 or KH36 (with a huge number of kms and many a steep hill as also living in Sydney). On the KH29 I was running the Duro at no more than 22psi on road (18 on trails), 42psi would rattle my old bones apart.

Feels like I’m writing this comment every time this topic comes up: Material alone does not determine stiffness. It’s just one variable in stiffness of a frame. Tube choice (diameter, shape and wall thickness) and crown design are equally, if not more important.

Of course, to make it a bit more complex, these properties are not fully independent, because for each material, you have to choose different tubing to achieve the same strength, which is why the common cycling wisdom is:

- Aluminum >titanium>steel in terms of finished frame stiffness,

while the materials youngs modulus (which decides stiffness) is:

- Steel(~210Gpa)>titanium(100Gpa)>aluminum(~70 Gpa)

Reason being that since aluminum is a lot less dense, you can make thicker tubing diameter and wall thickness for the same weight compared to steel, resulting in stiffer frames. On unicycles steel frames tend to be less “optimized” in terms of strength to weight, so they are often as stiff or stiffer than aluminum frames, simply because they are “overbuilt”.

Long story short, especially if you are getting one custom you are not faced with a choice of a “flexy aluminum frame” vs. a “stiff steel frame”. @jaco_flans (and owners of his frames) can correct me on this if I’m wrong, but I believe his crown design should make his aluminum frames fairly stiff side to side. I don’t think you could do a design like that with steel in a reasonable weight.

I think that applies for either one. It’s a whole lot of material that if you made it out of steel is either quite heavy, or you’d have to choose such thin material that I’d start worrying about buckling/denting.

Love seeing my two frame pop up here like this. (Two on the right).

I think this really is a genius design and inspires a ton of confidence in terms of stiffness.

That’s coming from someone who admired the KH style which in contrast doesn’t look (visually speaking) as ridged in the crown department.

I guess you’ve interpreted @Unicyc’s message the wrong way. An under-inflated tire does not make the frame flex more. However, the tire itself is more flexible than a well-inflated tire that keeps its shape. I don’t think the pressure has a lot of impact on the width of the tire, but it’s enough in some cases to make the tire rub against the frame. As @Unicyc mentioned, this is usually experienced when climbing a hill.

Frame material makes a difference in stiffness, given you’d have the exact same designs, different materials would feel different. Materials act as some kind of weird black magic though. In Unicycling, we dont feel those differences as much as on bikes since the frame design is fairly simple.

Bigger tube usualy equal stiffer, not only because it’s bigger, but because the surface of contact with the other tube it’s welded to is larger. Then again, weld a gigantic tube to a soda can, it wont be stiff. There’s alot of things to consider when choosing material and design.

My crown design on Aluminium frame has proven a good feel to me and to other riders. It also has a good amount of style points ![]() I make steel frames different, because of material availability and the fact that it needs less wall thickness for the same strength. Steel offers more responsive ‘‘spring-back’’ and feel to alloy, I use 4130 Steel, mild steel wouldn’t offer the same feel. Titanium is actually pretty flexy material, but you often see it on bikes that are made for longer distances, where a super stiff frame wouldn’t be comfortable!

I make steel frames different, because of material availability and the fact that it needs less wall thickness for the same strength. Steel offers more responsive ‘‘spring-back’’ and feel to alloy, I use 4130 Steel, mild steel wouldn’t offer the same feel. Titanium is actually pretty flexy material, but you often see it on bikes that are made for longer distances, where a super stiff frame wouldn’t be comfortable!

So, you can choose to make frames the way you want, material choice will help get to your goal, but it’s not the answer. The wall thickness, size, type, design all play a role.

And the weight question, here’s some stats based on the last 36’’ I made out of 4130 steel. All weights include bearing caps and bolts. It’s heavier, but it’s not a brick, and it feels awesome apparently ![]()

4130 Steel frame with intergrated seatclamp, powdercoated: 877g

KH36 aluminium frame: 810g

Nimbus Oracle 36’‘: 765g

Qu-ax RGB 36’': 640g

I somehow have a feeling that this question has been asked before but I’m unable to locate the post. So, I bought a Mad4One frame for my Schlumpf wheel, however either my spokes are too thick or the frame is to narrow:

What are my options? I don’t want to order every possible frame only to notice that I run into the same problem with every frame. Could someone point me to the place where this has been discussed before (if it has..)

Thanks ![]()