New Schlumpf Hub

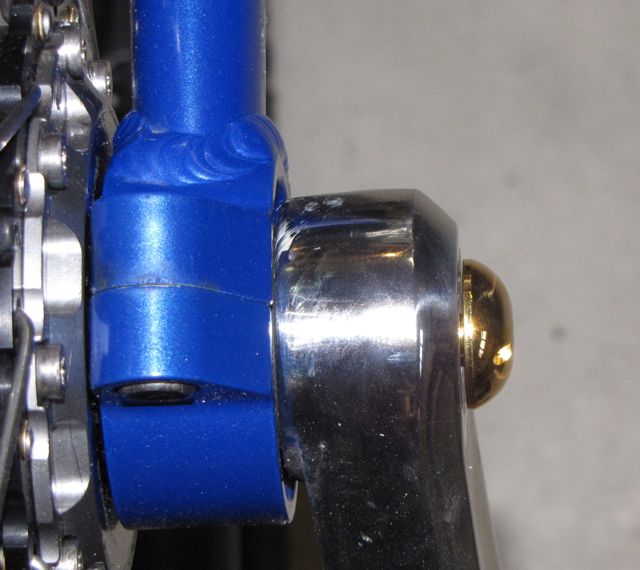

A large box arrived from Mr. Silva a few days ago. I opened it to find a nice Schlumpf hub built into a 36” wheel. I gathered the parts I had lying around my garage and assembled a 36” KH guni. It all went together well with a few torque wrenches and some care. (I am still not sure how far the buttons should protrude. Right now I can slip a paper card behind them when they are extended. I might take them in 1 mm.) I put the gold button on the right and am using 125/150 mm cranks with the pedals in the 150 holes.

I assembled the buttons with a Wiha economy torque wrench, which worked very well. It is a 2 Nm fixed torque wrench with a 2 mm hex blade for about $50 which makes the process very simple. I would recommend it:

http://www.wihatools.com/200seri/291serie.htm

The first ride was uneventful. I set it to low gear, mounted and rode around the block without any problem. I do not usually ride 150 cranks, and the tire is a bit heavier at the hub and lighter at the rim than my other 36” so the feel was slightly off, but I was easy to ride.

I switched to high gear and tried mounting. What a disaster! I usually do a rolling mount, but my pacing is all off because the cranks do not rotate with the wheel-duh!

I switched to a tire-grab mount, which got me on top of the wheel. I set off, but the tire did not and I ended up stepping off the unicycle. I repeated this comic dance several times before I gave up. The tire just does not want to move in high gear.

I regressed to an assisted mount holding onto a garbage can. Now I could get up, and starting off gently allowed me to get the tire moving. Unfortunately, my reflexes were all wrong, the tire moved too fast on my down stroke (1.5 times!) and I ended up stepping off the back. I repeated this mount several times and eventually managed to stay on for a few pedal strokes. At that point I started to get the hang of it and mounted and rode until I could ride around the block in high gear. It is much more sensitive to balance than in low gear, and I did a number of low speed UPD, most commonly stepping off the front when my attempt to accelerated failed.

The next day I rode around the block in low gear and in high gear and then tried shifting. I began in low gear with a rolling mount, and managed to shift to high gear by twisting my right ankle in until it rubbed the button. After 2-4 strokes this shifted it into high gear, and I immediately fell off. I downshifted, started again and once again managed to shift. This time I stayed on! I practiced this a few more times, mainly managing to ride through the shift.

I tried the same foot sweep to downshift and it eventually worked. I rode around the block, which includes a very small hill, and upshifted and downshifted a number of times successfully. This is a very cool unicycle!

I am shifting by positioning my heel to hit the crank. Sometimes it shifts on the first round, but more often the shift comes after a few strokes. I assume I will be able to manage it better with practice. I am shifting at very slow speed. Is this typical, or do some of you shift at high speeds? My shoe size, 10.5 (American) works fine shifting with the 150 cranks.

I am used to shorter cranks on my 36, but high gear with 150 cranks is a bit dodgy for control at this point. I basically must hold the seat so I can accelerate the unicycles out of precarious situations. I know some of you use 165 cranks for a 36 Schlumpf, and I can see why. I will stick with 150 cranks for the time being, but I am riding very cautiously.

Do you have any words of wisdom for a Schlumpf beginner?

Scott

Thankfully I managed to hammer a torque bit in to the hole so I could slacken it out

Thankfully I managed to hammer a torque bit in to the hole so I could slacken it out

There are places where high-gear riding is starting to come together, but I am not a speed demon yet.

There are places where high-gear riding is starting to come together, but I am not a speed demon yet.