We’ve had a bit of a life emergency here, but thankfully my wife is alive and recovering. So this project was naturally on hold. However I need something to distract me in the evenings so I’m back pondering this Schlumpf project.

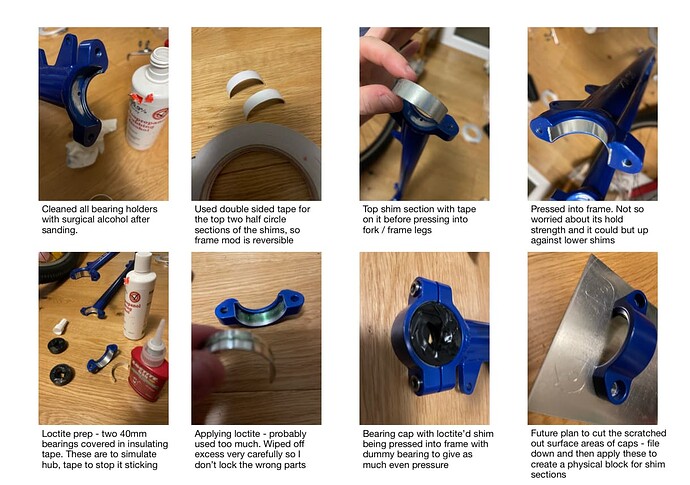

I have already made some head way with the washer idea, so this may be something I continue to tinker with. Sadly (however it’s good I think overall) the loctite in the KH frame legs didn’t work or stick so I removed them and cleaned it all down.

Leaning towards returning the KH36 to fixed wheel duty and my focus has shifted to trying to use the older NightRider frame in the Penny.

I confess I don’t like breaking something that is already custom built however I don’t have a passion to ride a 36er Penny so I feel pretty sure I’d enjoy using the frame as a G36er and not have to worry at all about shims.

When I first took it apart I thought reverting it back to unicycle duty would be null and void and a dead end. But on second review I think I may find my way there - and more easily than the shimming of a KH frame.

There’s a stem post welded into the previous seat post space and the clamp area has been cut off. I don’t know anyone local that is friendly enough to remove stem and weld a new seat post housing - but that would be ideal I think provided it doesn’t weaken the frame.

The stem appears well and truly established in the post hole and I presume steel is going to hold up from the weight of someone sitting in a saddle mounted to it above.

That’s the new problem to solve. How I attach a unicycle saddle to this bear 22.2mm pole.

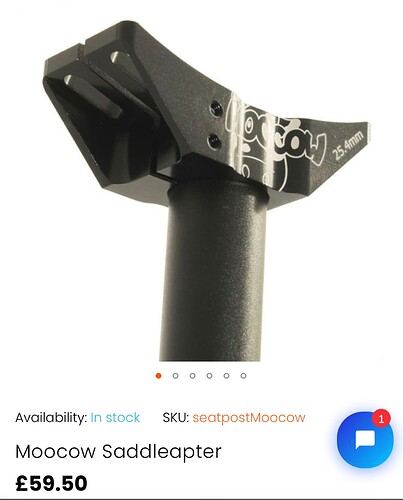

Enter this item I searched for, as it could be a quick win if not that amazingly sturdy. I’m 5’ 7” so I don’t think there’s in fact a ton of flex on any seat post for a 36er and I generally have a small amount of the post above the frame.

This item would allow for a very small amount up and down adjustment but I’d probably just aim for it to be at my heigh and then leave it.

Alternatively I’m thinking of using these items:

Which chimes in with the good suggestions on the Trading Post post from @JimT and @Unigoof ( )

)

I’d use the shim to pad the pole out and up to match the Moocow mount and then file down the lip on the clamp so I can clamp the shim at the bottom of the stem / where it meets the frame. This would give added support to downward loads I’d hope into frame sections itself rather than relying on the welding of the stem internally.

So I’ve exchanged problem of the 40mm bearing shims for this seatpost and saddle mounting affair. But I feel it is likely the best route for hub longevity and safety as once the saddle is set and works I’m unlikely to shift it around much. And if I find a friendly welder perhaps I can find a more beautiful solution.

Odd side comment to this - the frame has been already cold set to 100mm and was run backwards when in Penny mode. When mounting the wheel is the orientation as you would for a unicycle I notice the wheel no longer runs dead centre to the frame. It’s not a truing issue as the wheel is true when checking in the KH frame and the build is ace - but it is more something to do with how the frame was set to 100mm I think. Odd all the same that this changes when you flip the wheel?!?

I think I’m going to have to live with it as my guess is it shouldn’t matter too much - I don’t fancy taking the cranks off and reversing the way the Schlumpf wheel runs (backwards, gold left, silver right) - but if brake rub is the next issue it might just have to do that.

Any comments or suggestions always welcome