I wanted to build a new 36" ultimate wheel.

There are two rim options:

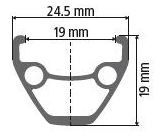

- Heavy and expensive Stealth II rim for 139€ + shipping

- 2 x light weight DT swiss 533d rim for 2 x 40€ and DIY like I did with the DT swiss 466d 7 years ago: Leichtbauthread

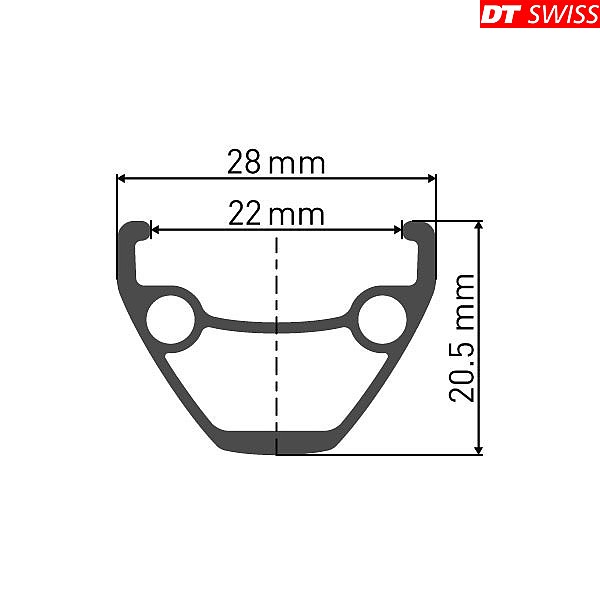

So here are the DT swiss 533d rims:

But wait…

These are new rims. Warranty void if seal is broken. Proceed? Definitely yes!

That looks so much better now:

Wrong size! Expand the small 28" 28 hole rim:

Rebuild my bending machine for the DT swiss 533d (as now it is set up for bending the Mavic CXP rim, which didn’t work out so good).

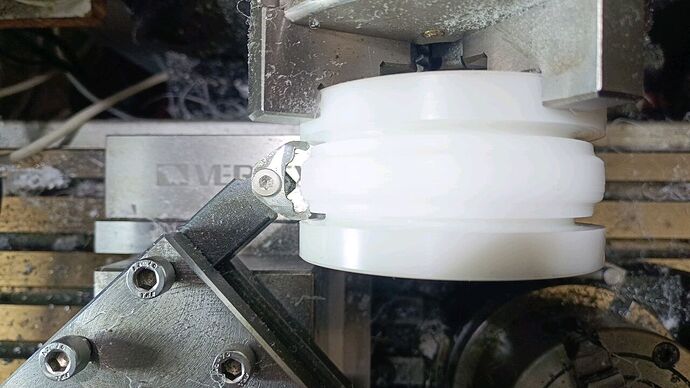

I used the bench grinder and a jig saw to fit a metal plate to the exact dimensions of the rim’s cross section and used this metal plate to groove the pom rollers. (The scratches on the plate were created after everything was finished):

3 bending rollers are required. Number one:

The holes for the bearings are prepared:

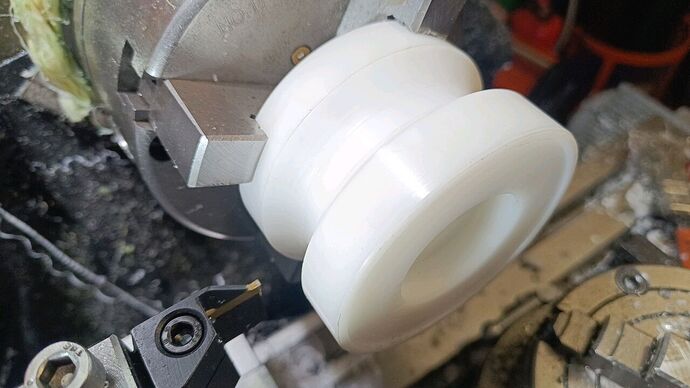

Perfectly fits the outside of the rim. Roller 1 is finished:

Roller 2 & 3 get an additional groove to center- mount the roller propulsion:

Unfortunately I have no pictures where I created the aluminium roller propulsion parts. The roller propulsion fits perfectly into the center mount:

Machining the inside profile of the rim:

Perfectly fits the rim (maybe the groove is much too deep, because I had much better results concerning stressed eyelets with DT swiss 466d, wooden rollers 2&3 and not so deep grooves, but wooden rollers break after 1 rim):

But wait, rim’s eyelets require space:

The eyelets have space now:

Drilling the propulsion mounts not too deep:

Tapping works in this short hole because I made the screws even shorter:

The DT swiss 533d rim bending construction set:

Bearings inserted:

The chain drive with my 6 tooth sprocket will have a force increase of 24/6=4 :

Machining the 6 tooth sprocket took 3 tries some years ago:

Propulsion mounted exactly in the center:

Sprockets mounted:

Roller axis M16 with adjustable chain drive hight:

Mount and counter nut it on the vice:

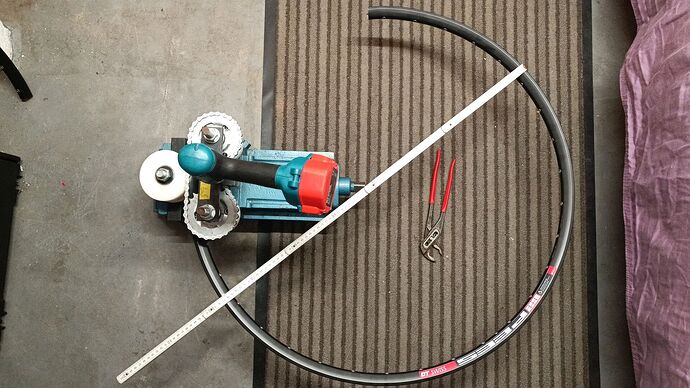

The bending machine:

The cordless screwdriver propells all:

Let’s go. Press the button to go from 28" to 36", I do it in many passes:

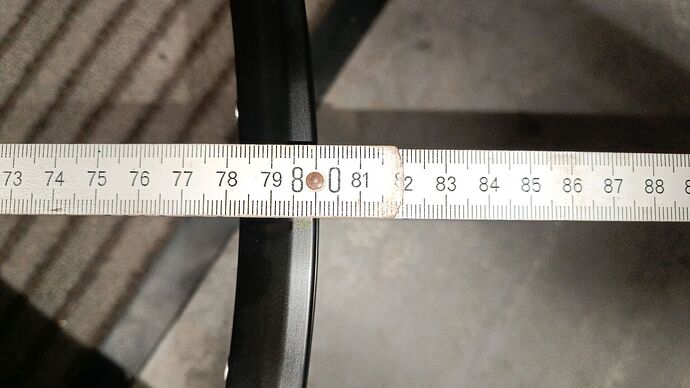

End dimensions reached at the mark:

Nearly done:

80cm, that’s it:

Cut it, it is just half of a 36" rim:

I turned titanium pins to ~3.94mm on the lathe and bent them by pressing on the floor, heated with a fire torch:

36" radius pins, the scrap rim parts help:

Grinding both halves simultaneously to a perfect fit and length takes much time, interrupted by tire mount tests:

Loctite the pin inserts in place:

That’s it 2 x 36":

The weight of 36" converted rims:

-

DT swiss 466d is 619g (2 x 18€ special offer, 28"/28h very seldom available, best bending results, rigid enough for workdays jump mounts for the last 7 years)

-

DT swiss 533d is 767g (2 x 40€, 28"/28h is standard, higher system load than the 466d)

-

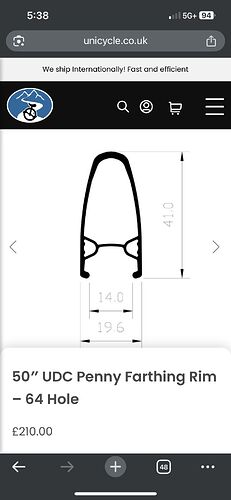

Stealth II is 1090g-1130g (139€ + shipping), 42mm wide.

![]() :

: