I’ll try not to babble on too much in this thread (something I often do when talking about unicycle projects). So here it is…

The original custom frame

In early 2003 I had my first custom muni frame built. I adored it, except for the horrible lack of side tyre clearance (1-2mm or so). It was light, rigid, beautiful, and yellow.

Original thread - http://www.unicyclist.com/forums/showthread.php?s=&threadid=21441&highlight=custom

Design changes - http://www.unicyclist.com/forums/showthread.php?s=&threadid=21540&highlight=custom

Bearing holders - http://gallery.unicyclist.com/albuo16/aak , http://gallery.unicyclist.com/albuo16/aal

Frame crown - http://gallery.unicyclist.com/albuo16/aat , http://gallery.unicyclist.com/albuo16/aav

Completed custom muni pics - http://gallery.unicyclist.com/albup21

I sold the frame to a friend who has built it into a beautiful light muni with a smaller tyre and rim. I went onto another frame…

The intermediate frame

I was given this old prototype frame from unicycles.com.au . This is the one I’m riding with for now. I don’t like it because although it’s really rigid, it’s also really heavy, the brake bosses are mounted poorly, the bearing holders aren’t quite the right diameter, and it has the same 1-2mm side clearance as my old frame. I’m planning on giving it away and getting a new custom frame made.

Here’s a thread about it - http://www.unicyclist.com/forums/showthread.php?s=&threadid=34178&highlight=custom+muni

The future custom frame

I’m changing frame builders this time, to a friend of mine who is a keen muni rider and very skilled at this sort of thing. This is him - http://gallery.unicyclist.com/album373/DSC08598 .

As I said, I adored most aspects of my original frame and hate most aspects of my current frame. My future frame will have the best of both…

- Light weight (under 1kg)

- Ample clearance (I meant it this time ;))

- Moderate rigidity

- Elegant beauty

More details…

Twin brake bosses for HS-33’s

- This time they will be mounted by a unicycling frame builder. As you can see on the intermediate frame, I’m currently running my Maguras off single bosses and it’s horrible.

Long ‘neck’

- 200mm long leaving only about 25-30mm for downwards adjustment. This way it will be stronger and also look nicer in that it will carry the colour scheme right up to the seat

Brake cable out of the way

- Nathan (the framebuilder) suggested this and I think I will go with it…having the braided brake cable either passing inside the frame to get it out of the way of sticks, legs, etc, or having it clipped to the frame the same as on many bikes.

Custom brake lever mount

- I’ll most likely get Nathan to make me a small brake lever mount the attaches to the front of the seatbase. I had a lot of trouble tracking down bar ends for anything bigger than 22.2mm tubing and this time I’m going with 25.4mm.

Colour scheme

- I like this colour scheme more and more each time I think about it. I’m going for white, black, and blue as my main three colours. White frame, black seat, rim, and tyre, blue pedals (Jim Cielencki’s) and seatpost clamp, and the chrome spokes, hub, and cranks. As I mentioned, the neck of the frame will extend to almost seat height. Here’s an edited picture of my old muni to show roughly what it will look like…isn’t it beautiful? - http://www.unicyclist.com/forums/attachment.php?s=&postid=286369

Questions

Seatpost size

- I’m very much undecided about this. What is standard on most quality munis? 25.4mm? Thomson bike seatposts are available in 25.4 which is a consideration I had for the future. For now though, I don’t want an adjustable seat angle.

Wheel size

- For now, I think I plan to stick to a 3" Gazz on an Alex DX-32. Running a 24" Large Marge would mean having to mount the brake bosses wider apart than usual which I don’t like, and I think a Gazz on a DX-32 offers me enough folding prevention. I also want a reasonably light wheel, and the LM with that future 4" tyre (or 3" Gazz for that matter) would not be light. What do you think? Should I allow that extra bit mroe clearance in case I want to eventually run a 4" tyre? I think as it is it would just squeaze in there, but I’ve been riding a muni with a just-squeezed-in-there wheel for two years and I hate it!

Any corrections or suggestions for my current frame design?

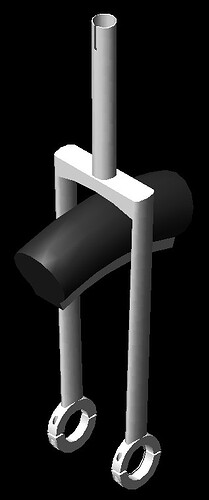

3D model

As you can see, it closely resembles my original custom frame…I loved that frame.

Frame specs - http://gallery.unicyclist.com/albuo16/Muni_Frame_Details

Isometric, shaded, view of back of frame - http://gallery.unicyclist.com/albuo16/Muni_Frame_Iso_Shaded

Front view, shaded, no wheel - http://gallery.unicyclist.com/albuo16/Muni_Frame_Front_Shaded

Front view, shaded, with wheel - http://gallery.unicyclist.com/albuo16/Muni_Frame_Front_Shaded_Wheel

Isometric, shaded, with wheel - http://gallery.unicyclist.com/albuo16/Muni_Frame_Iso_Shaded_Wheel

Isometric, wireframe - http://gallery.unicyclist.com/albuo16/Muni_Frame_Iso_Wireframe_Black

Isometric, shaded, wheel slided - http://gallery.unicyclist.com/albuo16/Muni_Frame_Iso_Shaded_Wheel_Slice

Please let me know what you think. Your suggestions really helped me when designing my original frame.

I’m very excited.

Cheers,

Andrew