alright, I’m home from school. I’m going to sketch out my idea for a derailleur based uni. it will require a custom tabbed frame, hub, and will absolutely need to be used with a bar, as there is a pretty basic clutch involved as my work around for the direct drive limitation of a bike derailleur. I will post it shortly

That sounds insanely difficult!

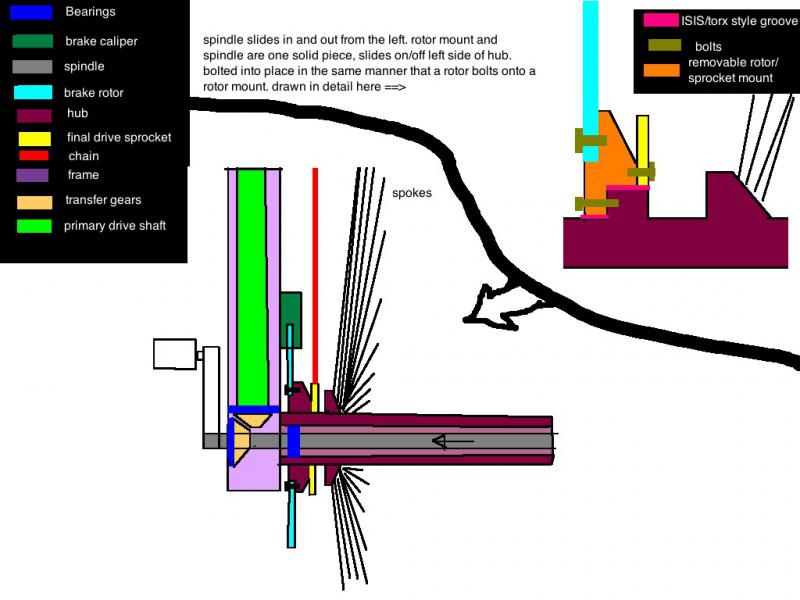

alright, here is a dirty mspaint drawing of the lower half. I didn’t bother adding much detail in the frame part, since that isn’t really important. the bearing between the spindle and the hub is not actually where it should be, so ignore that one bearing. the hub would mount to the frame itself via a larger bearing, just like on current frames. the hub would be entirely free from the centre spindle, driven by the chain.

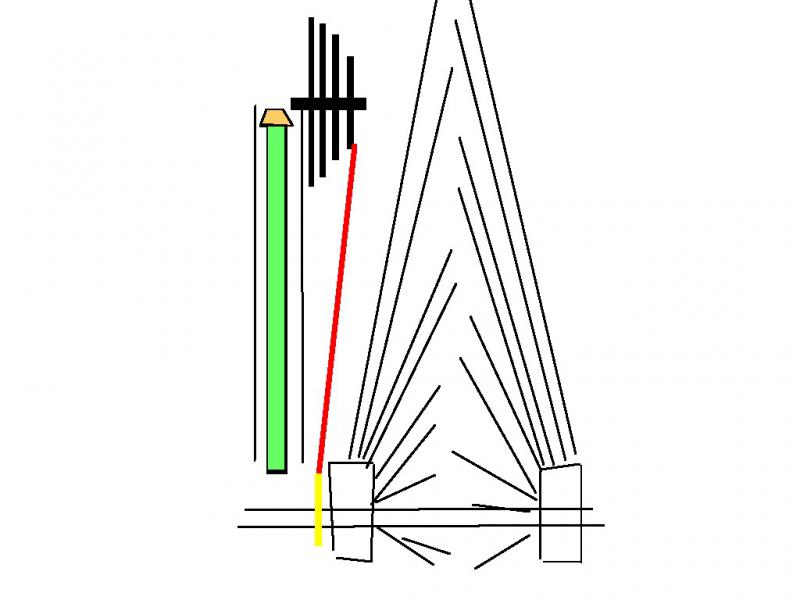

on the top half is where I think I have a good idea. throwing the cassette up top has some huge advantages, one being that the shape of the cassette fits nicely into the outer edge of the wheel, keeping the spokes free at the hub.

the derailleur will be assisted with a clutch as I’ve said. the first 1/4 stroke of the clutch will disengage the cassette from the driveshaft, and the last 3/4 of the stroke will actually slide the entire cassette down a few inches. this will take the chain tension job away from the ill equipped derailleur, eliminating the main problem that derailleurs have with direct drive.

one significant downside to this is that it will take a good 1 second to fully disengage/reengage the clutch, plus the amount of time it takes to shift gears, which will leave the rider coasting for the time it takes.

anyhow, I am going to go make some food then draw the derailer/clutch mechanism. I probably won’t be done it for a while ,since it will require a few separate drawings to explain.

It goes through the bearing?

Cool thread!

Why don’t we have more gears? The engineering problems are only challenges, I wouldn’t call them barriers. I think the reason we don’t have them is purely economic. If I could know the answer to one question on this topic, it would be, why hasn’t Schlumpf put out a 3-gear hub? No one knows the market and tech better than him, so I think he’s probably got the best insight of anyone as to where we are on this and where we’d need to be to get more.

Another thing I find interesting, that tells me there isn’t enough of a market to support speed-oriented setups is the lack of any single-speed geared unicycles on the market. Can’t remember all the details… wasn’t there going to be someone putting out unicycles similar to the “Purple Phase” or whatever, some time ago? That was a really cool setup.

Very neat idea, I haven’t seen or thought of quite that one before. Looking forward to the other drawings!

You may want to search the forum for geared unicycles and geared hubs. There are a number of threads which will describe the complexities and limitations with designing and riding geared unicycles. I’m always astounded at how easy people who have not done this think that it is.

The semi-jackshaft design is almost workable. A full jackshaft design is a proven system. The top half, where you intend to employ a clutch to 1.) transmit the full drive torque and 2.) do some so-far undesigned camming operation to 3.) disengage and re-engage the driveshaft and finally 4.) translate the cog cassette is where you may run into some difficulties.

A friction clutch to handle this kind of transient torque requires a large surface area and large release spring force. It would necessarily be a large and heavy component. Spline or rachet systems are better suited to this.

Designing a cam system to perform multiple functions is tricky business. I don’t think you’re going to be able to pull this off in the real estate available. I did, however, predict incorrectly that no one would be able to shift a unicycle on the fly.

The driveshaft as shown uses some kind of miter or bevel gear transfer. This has no travel. In order to accommodate a vertically moving cog cassette the driveshaft would have to be telescoping and splined in the telescoping region. This is heavy, cumbersome, and it is difficult to make a component like this move freely.

The idea of translating the cog cassette vertically while maintaining tension in the chain and shifting from one cog to another with a very short overall chain length seems far-fetched to me at best.

Aye, there’s the rub to most of these types of devices. While it’s one thing to make a functional multi-speed unicycle (I’ve seen several), it’s quite another thing to make one that’s actually “useful” to ride. Or even enjoyable. Useful, as in not so heavy that you wouldn’t want to lug it on a ride of any length, or not reliable enough to be comfortable to take on a long ride.

…In any gear. Before you invest too much time in building a gear-changer, try taking a ride on a geared-up unicycle. Any type will do; maybe someone in your area has one? I used to put big sprockets on my Giraffe and ride it at nearly 2:1. I learned early on the drawbacks of being geared up. Essentially, it’s faster, but much harder to ride. Net gain is pretty minimal, even with a Schlumpf.

Mostly the clean tarmac, though that would be better than dirty tarmac. The main “danger line” is crossed when you exceed the speed at which you can run out of a dismount. Ouch.

Speed wobble is probably not an issue, since you have to be pedaling the whole time. If you can learn to spin high enough RPMs, that will negate the types of wobble that seem to affect other types of vehicles at really high speed. Mostly because the speed won’t be as high.

Smart man! Though I can ride with very good stability at speeds up to 18mph, at that point nervousness comes in and inhibits me really pushing it. And even at 17mph or so, nobody’s perfect…

Mostly to win the race.

Yup. Nobody seems interested in making them at this point, since they would probably cost most of the price of a Schlumpf, but be much more limited. A unicycle that only has a high gear would really suck on hills. On a 36", the size of my Schlumpf, it would be basically useless for me.

the clutch isn’t friction based at all, but is the most questionable aspect of my idea that I have so far. it is either fully engaged or fully disengaged, but I fear that it would degrade quickly. the vertical driveshaft spins a horizontal bevel gear. that bevel gear is bored with grooves. the hub of the cassette has the same grooves, and the shaft that connects the cassette to the bevel gear slides in and out of the bevel gear. I’m not sure if the grooves will wear down in no time flat, but this is my fear. if there is a way of making this pull-pin engagement system work, then I think that the rest will work pretty well. when the chain is on the largest sprocket, the chain will be directly connecting the hub sprocket with no slack in the chain, and the derailing cog will be out of the way. the derailing cog engages while shifting to the smaller sprocket, but is not sprung at all. the cassette is sprung while disengaged to enable shifting, but when re engaged, it is firmly mounted. the derailing cog can only shift between its gear positions, which means that it’s rigidity is not affected by the chain going forward or backward.

anyhow, I have zero plans of building this, so no worries there. if you can’t tell by my terrible drawings, I don’t know anything about design, much less a machine shop ![]()

I do have an alternate idea for a derailleur that would eliminate the need for a clutch and let the cassette remain stationary, yet still handle force from both directions, though it would leave up to 3mm of play depending on which gear you are in, and would have to be built pretty strong

Why not more geared unis?

The number one reason is…

unis are fine the way they are

Let’s face it, even if we wanted to go faster, we rarely would unless on straight and level ground.

All of my riding is offroad, 26/29, 95% single track, 5% jeep roads or gravel roads. It is only on the roads that I’d have any interest in going faster, but for the extra weight, complexity, and cost, it’s just not that big of a deal.

I have a 36er and on the rare occassion I ride it, which is too rare, I am on gravel and dirt roads. If you’ve ridden a 36er in these conditions then you already know that they’re plenty fast enough as they are configured.

The OP is a novice rider, so it’s not an odd question to ponder, but once you learn to ride more varied terrain you’ll see that unicyling, unlike biking, is multi-dimensional, often requiring backwards and lateral pedaling movements as well as hopping, so gearing is really not as much of on an issue as you’d think.

If you are really wanting speed, you are probably wanting a bike.

Now crank length and Q factor, those things DO matter

Too complicated, too heavy, too expensive, not very efficient … 2 years ago I worched on such project with my previous engineering school and conclusion was : not feasible.

Gears are cheap, light, easy to machine, efficient. One single epicycloidal gear train is enought for 3 gears

…but has anybody tried one that has substantial drag when not engaged? Even a coaster-brake type of setup?

Argh, this is one of my peeves. Anytime somebody begins a phrase with “let’s face it,” what follows is almost guaranteed to be some unsubstantiated chunk of that person’s opinion that he wants to pass off as fact, without close inspection, by implying that those who disagree simply aren’t willing to face the unpleasant truth.

Back on topic: is it not possible that the reason you ride it so rarely is that it doesn’t provide the experience you want?

Wouldn’t comprehensive gearing (i.e., both up and down) be an advantage on varied terrain? Shift way down for the gnarly tractoring, use high gear on smooth dirt and pavement, midrange for the stuff in between?

While I enjoy offroad riding, the majority of my riding is, due to geography, on city streets (and sidewalks, and alleys, and gravel, and …). All too often, I end up taking my bike when I’d rather unicycle, because it’s not a good idea to arrive at my destination drenched in sweat, or because I can’t justify multiplying my transit time.

I would jump at the opportunity to acquire a next-generation gearing system that accomplished the following:

- Higher top ratio than 1.5:1

- More than two gears

I’m looking forward to the coming offerings of our community.

Okay, so I’ll add my 2 ct:

I am pretty open to new gearing ideas and all that. Having more than 2 gears could be very cool indeed.

But I am in the lucky position to have 2 geared unis, one 26" muni and one 36er and I am very satisfied with the Schlumpf hub with both setups. I believe the hubs have become very reliable by now, although I do have to keep tightening the crank bolts every once in a while (no loctite).

The main problem I see with more gears is the added weight that it would mean. The Schlumpf is very heavy already and I really wouldn’t want it to be any heavier than that.

On the 26er theoretically a lower gear for uphill and a higher gear for the road would be nice but on the 36" I don’t think an even higher gear makes any sense really.

Anyways, I think the Schlumpf is awesome and definitely worth the investment, even if it seems to be expensive. The amount of fun you can get out of it especially on the 26er is really worth it to me.

I am a little surprised that nobody has made a unicycle with a Sturmey Archer S3X hub on a jackshaft. Probably the easiest way to get more than two gears on a unicycle.

lower and higher?

I think the biggest reason why we don’t yet have multi-geared unicycles is the confusing fact that the middle gear with a 1:1 ratio would be called “neutral”. That just gets too mind-bending to consider.

The CVT I’m thinking of is simple, light weight, cheap, and efficient. Those are the only details I’ve got so far. ![]()

But seriously, the CVT technology we need might not exist yet. I’m just hopefully that some clever combination of gears, cones, chains, belts, and hamsters has yet to be invented.

My concept is made to have 3 gears on a 29"/125mm : lower gear (ratio 0.727) is equivalent to a 24"/150mm, direct (ratio 1) is 29"/125mm, higher gear (ratio 1.375) is similar to a 36"/110mm which is enought for me an wil give a very versatile off-road uni.

On a 36"/137mm it will be equivalent to a 24"/137mm in lower gear, 36"/137mm in direct, 36" Schlumpf / 150mm in higher gear which will be a perfect road uni.

Weight is also my main concern …

That sounds interesting. Let us know when it’s in production :p. I’ll go play with my 26er now. It’s a bluebird day :).

Nice spotting saska that looks doable if mounted above the wheel but its range is only 160% as opposed to the Schlumpf’s 150% and the gears have 1st and 2nd spaced close and a large gap to 3rd.I’m sure we will find a solution to the gear problem eventually.

john

Gear changing mechanisms discussed so far seem to be the button like on schlumpf, a wire shifter, and a brief mention of wireless systems. What about using a magnetic mechanism? I’m not sure how that would work but it would eliminate the tether of a wire system.