First, I’d like to link this thread here:

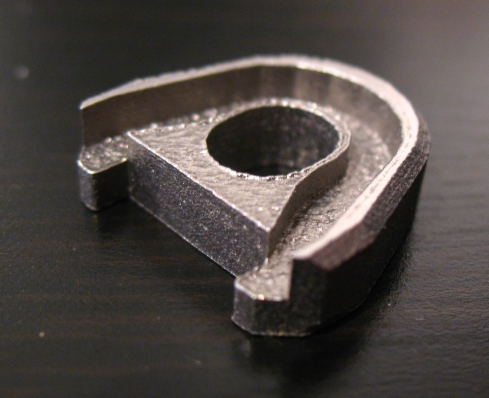

I have a printed (SLM - selective laser melting) steel adapter to fit a d’Brake on an old steel frame with stamped sheet metal bearing holders.

First, I’d like to link this thread here:

I have a printed (SLM - selective laser melting) steel adapter to fit a d’Brake on an old steel frame with stamped sheet metal bearing holders.