Brake lever mount:

Presuming that’s your design, how’s it been holding up?

Even the cheaper metal ones with the two bolt mount seem to have a lovely habit of flexing (on the mount), which I’d instinctively have thought would be likely to snap the layers where the bolts go through there.

I actually ended up never using that one. After first versions I made without the steel bolt snapped, I just used the metal mount from one of the other unicycles that I rarely used. I made this version before I sold that unicycle, to be able to sell it sort of as a “complete unicycle”. At that point I had also changed the saddle on that unicycle to one of the cheap qu-ax saddles with slightly different bolt layout and that why I never used it.

I did print a new one with different bolt spacing to fit the qu-ax saddle and as expected it was a bit flex in it.

I don’t know long it lasted since I sold the unicycle. (I did inform the buyer that the 3d-printed mount probably would break at some point and I recommend him to upgrade with a new saddle and brake mount.)

Don’t know why I didn’t design it with four mounting bolts in the first place, I was probably just lazy

There’s now a v2 designed for rail mount saddle bags:

https://www.thingiverse.com/thing:4932460

It’s not yet been tested carrying a bag, but from me scientifically trying with all of my might to snap it, so far I’ve failed so I’d guess it’ll be good for all small-medium rail mount saddle bags with velcro straps

I found a use for my 3d-printed brake mount yesterday, but not exactly in the way it was intended to be used.

The brake lever does not physically fit on the home made T-bar, and I was planning to mount my brake lever using an extra bar end. I didn’t have any laying around and used the 3d-printed brake mount as a (hopefully) temporary solution. It actually worked better than expected, not as much flex as I’d thought.

All bagged up

I’ll be riding my 36er with saddle bag attached via these hooks in the morning, I’ll let you know my thoughts.

A few months ago, I broke one of the two squares on my t-bar. After a few months of waiting, the modified version I designed has been printed at work, in steel.

Here are a few pics of it.

Wow, I couldn’t imagine the things I’d try and print with a metal printer.

Awesome!

Amazing. Mine bent a bit from a UPD within about a month of buying mine, but I think the bit that goes between them bent too.

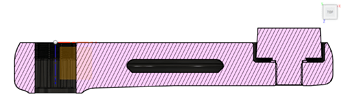

I wanted a crank that makes my stance width narrower, so I designed and printed these cranks.

(These are specific to the pedals I use)

I thought I’d give plastic FDM 3d printing a shot since that was available to me.

Fusion 360 file

Reason is I have a power meter pedal setup that adds about 16mm width to each side.

(It is designed for road clipless, and your shoe is on top of the pod. But, my platform adaptor makes it so your foot is on the outside of the pod)

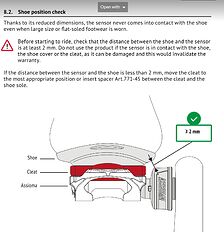

Picture from the pedal manual:

The bending and crank arm strength seems alright if there is enough material. I aimed for them to be heavier than my aluminum cranks. This version is 237 grams per crank. (200 lb-force and 66 lb-feet moment at the pedal thread hole; 4000N bolt axle bolt compression ~= 10Nm torque)

The problem is the ISIS interface and the pedal thread interface.

About 3 Nm is when the splines plastic deform and press fit onto the axle. After the crank bottoms out, 7 Nm causes the spline to start to be compressed and deformed by the bolt. I stopped there.

I think if the pedal thread area fails, then using a pedal thread insert might help spread the load out a bit more.

To make the ISIS interface better in case it doesn’t work, I have no ideas right now.

I would like to make a test rig to test the cranks, but need to figure out how to do that. I’m thinking of a metal crank on the other side, secured with some wood structure. Then use some straps and my body weight hanging from the pedals… Otherwise, I might just try riding them ![]() I’m kind of scared of what happens if cranks break while riding though…

I’m kind of scared of what happens if cranks break while riding though…

More photos over the last few years as I tried to make these pedals work:

Edit: Also, I am wondering if I should send the file out to see how much a machine shop would charge to make them if they are able to… The ISIS interface seems like a problem though. (Or metal 3d print…?)

Maybe you could consider doing what Mad4one used to do and have 10 round steel pins to form the Isis interface. I would expect that to develop some play (if you are using plastic) very quickly too, but maybe less quickly. Certainly a possibility if you have them machined (which is likely why mad4one did it that way), but it had some “downsides” when they pushed getting them lightweight.

I am not sure how much you want to move the pedals in. I think on a lot of unicycle cranks you could get away with machining away 5mm or more around the threads, at least if you want to use it on “only” a road uni. If you start with Mad4one agile, which are already 3mm slimmer than normal “0 Q-factor” unicycle cranks, that would give you at least 8mm each side. I’d need That would likely be a lot cheaper than having a complete new set of cranks made.

That is a neat idea. Do you know what the downsides were?

I am not sure how much you want to move the pedals in. I think on a lot of unicycle cranks you could get away with machining away 5mm or more around the threads, at least if you want to use it on “only” a road uni. If you start with Mad4one agile, which are already 3mm slimmer than normal “0 Q-factor” unicycle cranks, that would give you at least 8mm each side. I’d need That would likely be a lot cheaper than having a complete new set of cranks made.

I have it 10.5mm narrower than “0 Q-factor”. This is leaves about 2mm clearance to my Nimbus Oracle frame. The pod still sticks out a bit from the “0 Q-factor” plane. I would need a thinner/bent frame if I want to make it closer to a “0 Q-factor” position. This is my limiting factor in my opinion now.

Do you know how the Mad4one Agile cranks are 3mm narrower? Are they “bent” inwards"?

This does sound way better than making custom cranks… Pedal threads being about 13mm deep, I also agree maching 5mm off should be fine for road-type riding.

Do you know what the downsides were?

Snapping in half, likely because there was not enough material in the region around the crank interface. (To be fair, those were essentially prototypes where they pushed how light they could make it, the ones where they didn’t push that worked fine)

Do you know how the Mad4one Agile cranks are 3mm narrower?

As far as I know, they are just slimmer on the outside than the normal ISIS standard, this also means that some crank bolts stick out ever so slightly.

I was not aware that there was printing in steel being done,that is amazing. I would have though that models were made, molded then cast in metal. Is this actually printed or are we talking about cnc milling or water jet?

I am really disappointed in the fact that you can’t buy just that bracket or for that matter any of the components individually with the KH system. If one part gets damaged you have to buy the whole thing and they have not been readily available since covid

It is actually 3d printed.

Most of the time it is a metal powder that is melted with a laser. But this is printed in a plastic loaded with a lot of metal particles infused inside, and then cooked to join the metal particles. (You can look for the metal x system by markforged if you want more explanation).

And I have a doubt, I wrote that it was printed in steel, but I think it was actually inconel (a nickel alloy).

And yes, it is really annoying to have to buy a whole system to get those parts.

I’ve just got myself a snazzy new 3D printer (Bambu Lab X1 Carbon) so I’ve been thinking about printing stuff again lately.

I know nobody’s really had any luck with handles before, but I’m wondering whether 3D printing in nylon, and then wrapping in glass/carbon fibre would give me the required strength for it to be actually useable. Obviously dimensions would have to be a bit smaller to account for the fibre addition, but that’s no big deal to design in.

On the Mad4One ISIS cranks with pins, you stil need a slightly tapered intereface for the pins to slot into. This is typically done with a broach for the overall shape, and then a coining operation to add the taper.

Although at 1º you can maybe get away with this happening when the cranks are fitted?

Did you add a taper to your design, or accept that for one degree it might be best just letting the axle form that taper as you install the cranks?

You’re making me want to 3D print some cranks now

As far as I know, they are just slimmer on the outside than the normal ISIS standard, this also means that some crank bolts stick out ever so slightly.

I see. Some photos of other cranks they have even have a little cone shaped protrusion at the bolt.

I know nobody’s really had any luck with handles before, but I’m wondering whether 3D printing in nylon, and then wrapping in glass/carbon fibre would give me the required strength for it to be actually useable. Obviously dimensions would have to be a bit smaller to account for the fibre addition, but that’s no big deal to design in.

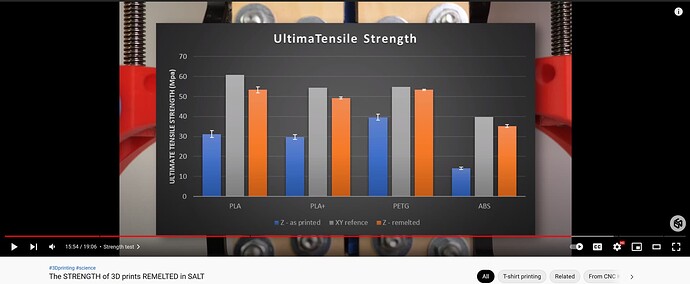

How about remelting in salt, as in this video?

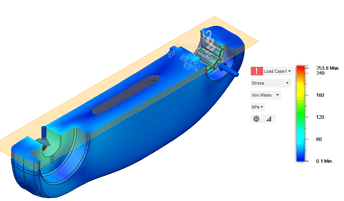

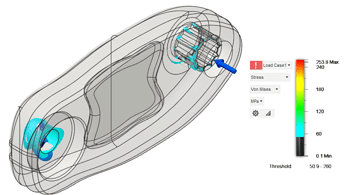

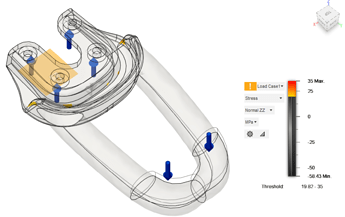

Did a quick simulation of Corbin’s handle with 50lb load:

The high z stress (seperating the layers) area is right near where Corbin’s sample broke. 30 MPa is right around the limit for PLA/PETG layer adhesion strength according to CNC Kitchen’s video. However, remelted, it increases nicely to 50MPa.

Did you add a taper to your design, or accept that for one degree it might be best just letting the axle form that taper as you install the cranks?

You’re making me want to 3D print some cranks now

Yeah, I have the 1º taper.

I initially tried a nominal press fit of 5mm as illustrated in the ISIS standard drawings, but increased it to 6mm. I will try more if these cranks loosen… ISIS standard recommended 3-6mm for aluminum cranks.

On the Mad4One ISIS cranks with pins, you stil need a slightly tapered intereface for the pins to slot into. This is typically done with a broach for the overall shape, and then a coining operation to add the taper.

Although at 1º you can maybe get away with this happening when the cranks are fitted?

I would have thought a 5-axis CNC could make the ISIS with pin holes along with the 1º angle. I assume needing a broach would make it impossible to get a custom one made by a normal machine shop.

On the Mad4One ISIS cranks with pins, you stil need a slightly tapered intereface for the pins to slot into. This is typically done with a broach for the overall shape, and then a coining operation to add the taper.

A 5 axis cnc would do that, or a rotary indexer on an angle. I’m not sure which mad4one did, or maybe it even works without the taper if the pins are soft enough, but I’m sure that avoiding the coining operation and associated tooling was the point of using the pins.

Brilliant bit of engineering I think.

I know nobody’s really had any luck with handles before

Lea Opitz had a 3d printed t bar at unicon, that apparently lasted for over a year now. I only talked to her very briefly, but maybe you can ask her what it’s made of.

I honestly think Corbins design has potential if you add material at the baseplate, not much reason to keep it as thin as the standard handles there I think.