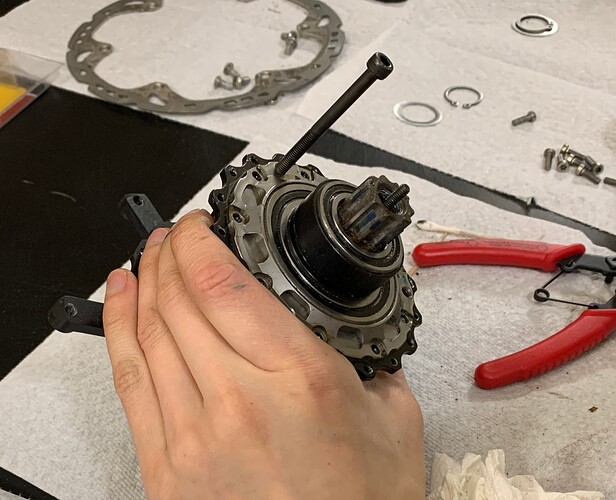

Trying to take apart a hub to do a complete clean and try an ATF oil bath.

Based on the How It’s Made Video,

I unscrewed the 9 T20 screws on the right side, but nothing happened.

I thought the left side and sun gear would be stuck as it was pressed in, but next I took out the two snaprings near the clamped frame bearings.

After I took out the two snap rings, and the sun gear + bearing came out. The large bearing was a super loose fit in the hub body.

The right-side plate and rest of the mechanism still seems stuck. I’m afriad to use too much force.

I noticed three M5 threaded holes on the right-side plate. Are those supposed to be used to pull the plate off?

Update:

I made a plastic piece for me to grab onto the right plate. My thought was three holes for the M5 screws to go through, and I could clamp the plastic part in a vise and pull.

But, I accidentall tightened the M5 bolts “too much” and heard small sound. It still felt stuck though.

Putting it in the vice, I couldn’t get it out as the plastic piece didnt have enough friction and was too weak to be clamped hard.

I became impatient and continued tightening the M5 screws more. It popped the plate off!