Wfat makes you think that? I’ve ordered a 100mm 32h hub for my G36. I hope I won’t have to file up too much of my frame or brake caliper ![]()

Today, I built a 36" braus 32h carbon rim on a 100mm 32h schlumpf hub

Indeed, on the non disc side the spokes are very close to the frame (flansberrium).It seems to me that it passes without touching, but it is very close.

On the disc side, I’m really surprised by the position of the disc… it’s much too close to the spokes for the caliper of my tech3v4 brake to pass. I added a washer (well, more like 9 washers…), but it’s still missing at least 2. In fact, you need a 3 or 4 mm spacer for the disc to be in its place.

What surprises me the most, in comparison with a BF, is that the flange on the disc side has been moved a lot towards the centre of the axle (I would say more than necessary). This leaves a lot of room for the caliper and the disc, but there is a piece missing that would allow the disc to be shifted at least 3 mm outwards.

That’s a real shame, I hope this is fixable ![]()

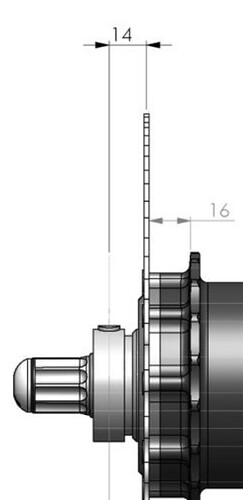

From my discussions over the design of this hub, it seems the required clearance of 16mm measurement from the rotor to the disc flange, was in fact meant to be 16mm to where the spokes would be (but appears to have been give to the flange)

However I’ve also heard that other unicycle hubs opt for the 16mm spec - but I’m thinking those hubs have much smaller diameter flanges so once you get up to the spokes at angle on a 180 or 203 disc things clear much more freely.

I agree it does feel like there is something missing in terms of spacers etc. once you start using more than 2 washers you’ll really want longer rotor bolts.

It’s great Florian’s confirmed we can use spacers, but the sad fact is nothing about how to set the rotor up is touched upon in the manual - which frankly is odd given this is the front and centre feature of the hub.

I’m positive it can be figured out and I just hope the feedback gets listened to openly ![]()

![]()

![]()

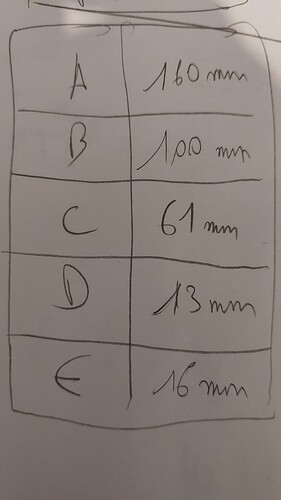

In this case, there is a problem with the drawing… I just took my Mitutoyo caliper (which I just bought) and I measure only 12 mm between the flange and the disc (instead of 16 mm).

For this 12 mm, there is 10 mm which corresponds to the hub body and 2 mm to a spacer which is aimed with 3 hex head screws.

If this part is indeed a spacer, it seems to me that a solution would be to replace this 2 mm spacer by a 6 mm spacer.

EDIT: In the meantime, I took the measurement between the centre of the disc (which is 2 mm thick) and the centre of the bearing. I find 16 mm against 14 mm on the drawing.

We read 17 mm, but on the drawing the measurement was in the center of the disk (which is 2 mm wide), so it’s 16 mm instead of 14 mm on the drawing.

That’s very interesting!

Looking at that drawing we can see that the disc when bolted on is almost flush with the main body/bearing - whereas when bolted to actual hubs it is stepped inwards.

Odd. Really hope you’ll be feedback back on this to Florian. Your measurement unpacks the core issue that has been causing the problems - as of course you’d be fine to use the caliper to align things!

I did fit my hub (with 180mm rotor) in a new unicycle (after re-lacing the wheel last week as result of the countersunk hole discussion). However the only disk brake I had available, a Shimano quickly taken from my muni, didn’t clear the spokes.

For now I did temporarily put that issue aside to solve later, since I normally don’t often use a disk brake when riding my muni or 36” and since I really wanted to try my new build this week during the British juggling convention.

One point of warning though; I originally mounted the hun such that the notch stuck into the hole already present in the m4o muni frame, and I at least “thought” that I torqued the bolts to approx 5Nm. During a few of the mounting attempts the wheel slipped a bit, and when I opened it last week I saw that the notch had carved a slit into the aluminium. But the bolts also took much less than 5Nm to remove. So I don’t know if I mistakenly used much less torque, or if the bolts loosened due to some other reason. But either way the bearing slipped, and damaged part of the frame in the process (the nearing itself looked fine, though). I now rebuild it and drilled a hole in the bottom bracket, and so far it seems to be fine. But I’ve also been a lot more careful to not put too much torque on the pedals when I’m high gear, so I’m not sure if this could happen again in the future.

[quote=“toutestbon, post:163, topic:273299, full:true”]

What surprises me the most, in comparison with a BF, is that the flange on the disc side has been moved a lot towards the centre of the axle

What about the spokes angle on the disc side?

I just sent an email to Florian Schlumpf:

Hello Florian,

Yesterday, I built the hub with a 36" rim and I have a first feedback to give you.

There is a problem on the disc side.

In fact, I couldn’t mount my brake caliper because the disc is too close to the center of the axle.

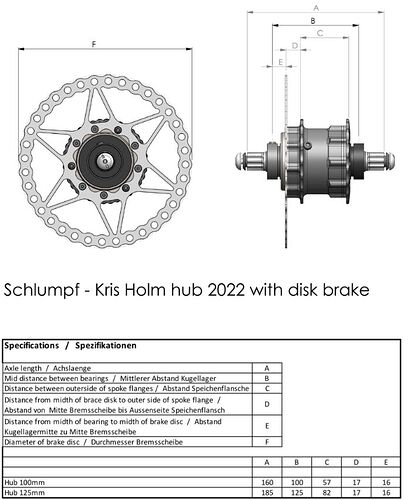

On the installation manual it is noted that the distance between the flange and the center of the disc is 17 mm (distance D).

I took my vernier caliper, and find only 13 mm for this distance:

10 mm for the hub body

2 mm for the spacer fixed with 3 hexagon head screws

1 mm to get to the center of the disk (which is 2 mm thick).

Of course, I can use washers to space the disc, but 4 mm is a lot. Did you notice this difference in dimensions between the drawing and the hub?

I wonder if there is a possibility to replace the 2 mm spacer by a 5 or 6 mm spacer. It seems that a lot of parts are removable on this new hub.

The drawing in the manual is different from the one published above by @mindbalance

But in both cases, the distance between the flange and the disc was 16 mm, it is missing 4 mm.

@Ant_1 The flange on the disc side is particularly thick (4 mm I think… I didn’t measure it before building the wheel). I assume this is to make it stronger, due to the high tensions on the disc side. I don’t know if this is a problem for the spokes…

WOW, thanks all the posting guni builders!

It will be so much easier for the rest of us following later in your footsteps.

But it seems like we have a critical lack of clarity on exact dimensions.

(or at least the Hub measurements seem different from the specifications!).

Like rotor to flange, flange to center (and inner width of possible calipers is needed).

Anyway, I have just done a heap of calculations for various rims (with “typical” ERDs) for 32 or 36 holes.

The idea (inspired by Hammer) is to get a proportional factor (P) to work out what proportion of the “depth” (that a spoke has from rotor to flange to center spoke line in axial direction) is available at a certain radial distance.

This radial distance is to the caliper, and I have calculated it for 2 typical rotor radii (90mm and 101mm).

My derived formula for clearance (e.g. at edge of rotor): X = DF + FC * P

(obviously the caliper width should be less than X).

DF = disc rotor to flange (inner distance) [maybe 12 to 17mm??]

FC = flange to center of hub (from outer side of flange) [maybe 17 for 100mm hub, 29.5 for 125mm hub?]

[NB for asymmetric rims, add the rim offset to FC!]

P is calculated below for various nominal rim diameters and hole counts:

for each case the P value is given at 180mm rotor edge and 203mm rotor edge.

(e.g. a 24in 32 hole rim has a P of 0.303 for a 180 rotor and 0.357 for a 203 rotor).

You can use this (with the depth measurements DF and FC) to derive clearance X for your particular case.

P_24_32 = 0.303 or 0.357

P_24_36 = 0.288 or 0.343

P_26_32 = 0.269 or 0.318

P_26_36 = 0.255 or 0.305

P_27.5_32 = 0.255 or 0.302

P_27.5_36 = 0.242 or 0.289

P_29_32 = 0.237 or 0.280

P_29_36 = 0.224 or 0.268

P_36_32 = 0.180 or 0.214

P_36_36 = 0.170 or 0.204

Note that clearly small rims have a larger value of the clearance factor, P.

And 32 hole has a trivially larger (better) P value than 36 hole, for any given rim size.

And of course a 203 rotor always has a larger P value than 180 rotor.

36 inch rim looks bad with 100mm hub, but 125mm is much better as FC is much larger.

In the unlikely event anyone is interested or wants to double check the math derivations,

I can edit that boring stuff into the end of this post.

(and of course I may have made a mistake somewhere, despite my own double checking).

I just checked dimensions of my 100mm hub. Florian increased flange interval by 4mm in comparison with the drawing.

Thanks for checking things - it’s really interesting / puzzling. I guess that shift makes for better spoke angles.

Do you think this is resolvable by a new end cap piece / or custom made spacer where the rotor currently sits?

I am ![]() crossing my fingers that this won’t require a full shell re machining and just some extra piece to push the rotor out.

crossing my fingers that this won’t require a full shell re machining and just some extra piece to push the rotor out.

I guess we’d be eating into the measurement of E - and that space is there for a reason but it seems like it could cope to get the rotor aligned and have spokes clear.

So we have a clearer picture emerging!

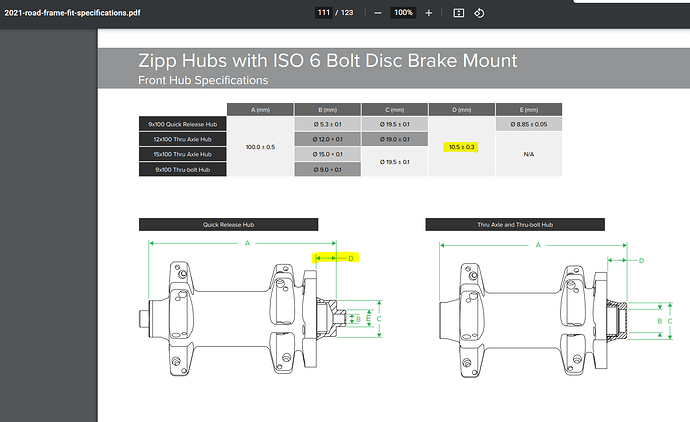

The measurement E (from disc side bearing center to midpoint of rotor) is 16mm and it HAS to be this value because of the IS standard which is used by the unicycle hub manufacturers.

[EDIT: I am not 100% sure about 16mm being the IS standard, but anyway I am assuming that, and also assuming that the issues that people have had with the new hubs are NOT simply that the rotor does not align with the middle of the slot between the disc pads (e.g. due to a non-standard rotor offset), but instead the rotor cannot go into place because the spokes are contacting the edge of the caliper body - please tell me if I am wrong].

The measurement D (from midpoint of rotor to outside of flange) is 13mm.

On the old specification drawing it was shown as 17mm (and the flange appeared to be thinner, whereas it is now 4mm thick?).

It is good that the IS standard has (I think) been adhered to.

It is good that the flange is now much stronger.

It is unfortunate that Florian’s indicative drawing seems slightly incorrect and that he did not anyway caution us to prefer the 125mm hub instead of the 100mm hub for the 36 inch wheel case.

If I use my calculations indicated in my previous post I can get an approximation of the clearance (X) between the tip of a 203mm rotor and the spokes, assuming a 100mm hub and a 36 inch rim with 32 holes and no spoking offset:

X = 12 + 21 * 0.214 = 16.5mm

12mm is the distance between the rotor inner surface and the flange outer surface.

21mm is the distance between the flange outer surface and the midpoint between bearings.

[16.5mm is APPROXIMATE caliper clearance but is affected by the spoke width and cross over, and at what radius the caliper protrudes most, and by the fact that my P derivation was based on a slightly different ERD value than the Braus rim, and possible rounding errors, calculation typos etc.]

Ways to increase chances of caliper clearance are:

- use a larger rotor (but 203mm was assumed for above calculation anyway!);

- find a smaller caliper (road bike single piston calipers may be narrower);

- modify the caliper by filing it near the contact area;

- use washers or similar to move the rotor away from the flange, but this may mean filing the adjustment slot in the caliper and filing the IS to POST adapter, so the caliper is repositioned outwards to align with the rotor (and the possible rotor movement may also be limited by the frame);

- use an asymmetrically spoked rim with a significant offset;

- use aero spokes(?);

- use a weird non-standard weaker spoke positioning(?).

Completely correct. We’ve taken to trying to align the rotor from the hub body as we can’t use the caliper as we’d normally be able to get it aligned.

This all now explains why things have been so incredibly tight.

Speaking for myself. I’d have jumped at the option if the125mm hub had a 32h option, but it is stuck at 36h only. This pushes anyone wanting a Braus rim set up to go with the narrower hub.

Adding to the list of your 7 fixes (which all seems helpful and valid by the way)

Number 8 - Florian recalls the hubs and recreates the shells to match the diagram and bring back the full clearance for caliper to spokes.

I highly doubt hubs are leaving the factory now. I think there has to be a pause on assembly and manufacturing. But if customers then receive a corrected product, those of us fiddling with washers will have to have the hubs redone surely.

I like that some of us have got it working for the smaller wheels, but then comes the point … do you want it to be out of spec? For something this new and valuable I’d rather have it remade and wait, than know it doesn’t match later hub shipments.

I have still got no message from Florian whereas @toutestbon has received its hub with the same features as mine, so I suppose you’re right. He may be trying to fix things. Hope he’ll find a clean solution!

Yes, I agree that it would be nice to have a 125mm 32H option - it seems very hard these days to buy a new MTB rim of any size with 36 holes.

As for changing the hub from how it is now built, I do not think that there is any “win-win” scenario:

- if the disc side flange is moved inwards, there would be more clearance, but at the expense of greater disparity of spoke tension (the current flange thickness would DEFINITELY be needed);

- if the rotor was moved outwards there would be 1mm of extra clearance for every 1mm of movement (which is actually a better result than moving the flange 1mm inwards), BUT there is a limit to this movement (e.g. rotor or mounting screws might hit some part of some frames), AND anyway then the hub would need to be shipped with an extra non-standard IS to POST adapter.

I’m surprised by this answer. You are not the only one who told me that 16mm was the IS standard (and someone else told me 14mm…)

I didn’t even think there was a standard for this distance… Having Flansberrium, RGB and M4O frames, I can tell you that the distance is never the same. However, the brake caliper support is often welded too far inside.

I’m going to make you a small collection of pictures of my brake setup on my unicycles. There is a common point: the caliper is never centered on the IS/PM adapter, it is almost always pushed outwards. And most of the time, I had to file the IS/PM adapter.

It would be enough to weld the caliper brackets more outwards. Why isn’t this done? Is it less solid?

To be fair, I did add " I am not 100% sure about 16mm being the IS standard" to my post.

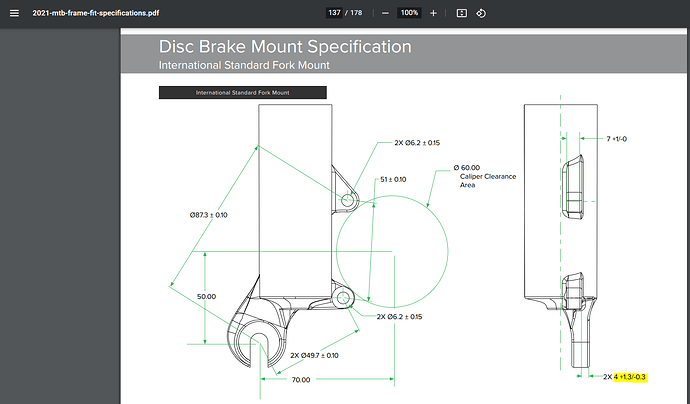

The IS standard defines the size of the bolt holes (6mm), the gap between the bolt holes (51mm), and the radii from the axle center to each of the two 6mm holes (49.7mm and 87.3mm). Unfortunately, some component manufacturers have minor variations. For example, Hope brakes. A safe build uses e.g. all Magura, all Shimano, all Hope, all SRAM etc.

The IS mount tab can vary so that the angle between the axle, the frame member and the caliper is flexible, but in practice it is usually made so the welded tab is not too big or weirdly angled.

However, I have a feeling that the distance between the tab surface and the rotor surface (which is important to us here) is not an official standard, but there is an approximate consensus between manufacturers of 15mm to 16mm. There is a frame builder’s CAD program that uses 15.2mm. When I looked at a few unicycles, I agree that there is a range of actual values (around this size). However most calipers seem to be Shimano, and the range of axial adjustment in the slots where the caliper sits on the adaptor must usually accommodate the variation in frame tab offset. But if changing brake systems from what came with the unicycle originally, it would not surprise me if sometimes a bit of filing or shimming is needed.

Luckily there is plenty of scope to easily modify an IS to POST adapter.

Yes, it could be modified to handle a rotor which was moved outwards beyond the scope of adjustment via the centering slots.

But how far can the Schlumpf hub rotor be moved outwards?

I don’t know, but it will eventually bump into something.

And it depends on the frame model.

Perhaps it can be moved enough to avoid caliper-spoke interference on a 36 wheel with a 100mm hub? (If so, HOORAY!).

I’m looking forward to seeing how people here solve this issue.

It sadly seems to be the way in the bicycle industry that multiple standards proliferate, and they are often re-invented or broken, and anyway we unicycle owner-builders hardly expect our bespoke creations to be “plug and play” part interchangeable with someone else’s bespoke unicycle.

But I feel sorry for Florian Schlumpf who cannot please ALL of us with any particular rotor location choice (but some optional rotor shims supplied with the hub might be nice!).

I just did a bit of testing (as I had the wheel removed anyway).

It’s not just about how far can you move hub it’s also about how far can you go without compromising strength.

Below pictures is with 3x1mm spacers behind the disc.

As you can tell this is about as far as you can go without affecting how the disc interfaces with the hub.

I tried briefly with 4x1mm. It still fits but it’s not a great fit and when mounted in my M4O frame the rotor bolts scratches the paint and my standard Shimano IS to postmount adapter would also need a bit of tweaking for the brake caliper to be properly aligned to the disc. I did find torx screws that have a lower head (2,1mm vs the standard ~3mm) so that will solve the frame clearance.

It seems to be that max optimal spacing is with 3mm washers and M4x14mm torx screws (standard provided with hub is M4x12mm). Anything beyond that will compromise strength and likely need small tweaks to even fit.

You could maybe use extra-flat-head screws, such as those ones:

https://www.visseriefixations.fr/tete-cylindrique-torx-extrement-basse-m5x10-inox-a2.html

I use them for my BrakeFast and there’s way much clearance than with usual screws.

SRAM’s front hub/fork specifications give a total distance between rotor mounting surface and ISIS tab mount inner surface of :

14.5mm +1.6mm/-0.6mm

The individual standards can’t apply to our parts since our hubs/frames are different…

But we can combine them and it should match.

My M4O and Nimbus frames’ tabs are all approximately centered to the frame/bearing. The tab on the frame is about 6.5mm thick. Therefore, the mount surface is 3.2mm inboard.

16mm Schlumpf E dimension - 3.2mm centered tab on frame = 12.8mm

It seems the disc tab and disc brake are too close together by about 1.5mm.

This would match @toutestbon experience that his calipers usually need to be pushed outwards.

On standard hubs, I am guessing they are designed to be as far out as possile already. Any further, the rotor bolts hit the bearing holders. Ideally, the ISIS tab is welded about 1.5mm outboard. But, things still work if they are welded in the center.

On a sclumpf, if the rotor bolts are not interfering with the bearing holders, then I would imagine that spacing the rotor out another 2-3mm would be helpful. However, the existing frames would likely have the tabs welded too far inboard, and should be moved outwards.