Looks great Vince. Nice and simple. I would love to test that thing out for you but I don’t have a proper road unicycle to put that on anymore.

Thanks Eric.

I think I’ll name it the DVL Horns, after seeing the revision made by a friend :

Also is it me or the clamps kinda look like they’re giving the horns?

Maybe it’s just me, but I would be a bit uneasy about that thing with sharp teeth staring at my crotch.

…while others would get their excitement out of it ![]()

Here are the latest modif before fabrication. Also I’ll try to get some anodizing done on the clamps (red would be cool), depends how much $ I can have it done for.

Any idea on the costs of a handle?

because I like the design (but I would use welded handlebars for the brake)

I don’t know the cost yet, depends if I do the machining/welding myself or have it done by someone else. I’m planning to do the first ones next week, so I can give you an update on the price.

Once I have the position nailed, I will probably go with a welded front bar too (like the PI bar).

But I think having a brake will not be much of a problem on this setup. I’ve thrown a lever in the assembly for reference.

I (and most riders) like the brake lever to be on the actual right (or left) handle.

This brake setup is way to hard to brake properly.

I dunno how much they might have changed, but the lever for my maggie is way shorter than the one in that render, and would probably even fit on the bar-end.

I have long levers on my maggies. My next handle is going to be set up really similar to that using the back T part of a T7 with bar ends as the font of the handle. I had it set up like that very briefly last winter and it worked well, even with heavy mitts on.

I could see it not working so well with the newer levers though.

Yeah the modeled brake lever is just a mockup, of more like a HS22 than a HS33.

I like ergonomic bar ends. And I might weld something like this to adjust the brake.

I modified my T7 with a bike seat sort of like in the early posts in this thread. To account for some of the weak welds and such, I attached a high-tension cable to the ends to offset some of my body weight while riding. I also included tensioners so that I can release the tension when I’m not riding.

I’m not quite done yet, though. I’m also planning on having some steel triangle supports welded onto both the front and the rear vertical plates surrounding the rails. I saw someone repair a broken T7 that way (can’t remember who it was).

The short bars in front of the seat help with downhill riding a bit. They pose somewhat of a risk in case of a forward UPD, but I’ve already had to deal with that issue a few times and I think I can build a reflex to avoid grazing it.

Cool design work Vince, elegant, modular, simple too. It’s great how different everyone’s solution to bars are!

Couple of things I wondered looking at your bars:

I guess you are a taller guy as it looks like the bar could only be used by a rider tall enough to have sufficient seat post exposed, and the ability to adjust the bars also depends on that.

Without a CF seat base there could be a fair amount of flexing up and down as well as side to side.

It seems quite vulnerable to damage from UPD’s.

Will it be tricky to adjust/tighten the bolts at the rear when the bar is fitted, as shown below?

Ouch, is that a unicycle or a surgical instrument? ![]()

![]()

TBH as inventive as it is it’s unnerving seeing guys use T7’s as top bars, even if as only temporary solutions.

That looks as if you’re about to invent the ejector seat for unicycles.

Thanks.

Yes, I have quite some space on my seat post, even on the 36er. It sure is not so simple for short people, some can’t even consider a T7 without cutting their frame!

I’m pretty confident about the stiffness of the DVL Horns. I have tried the Coker PIbar and it’s quite stiff. I use a very similar pivot/clamping system on the seatpost, and on top of it I use the front of the KH saddle (which is still relatively stiff) to stabilise the bar. Don’t look at it as pivot points when tightly clamped.

Flexing is as much an issue for this design as it is for the T7 touring handles. The alu tubing I’ll use is stiffer than the 4130 tubing used on the T7. Of course, in case of a really bad fall involving a car running over the handle, well the bar won’t be bendable to its original position ![]()

For normal UPDs, the bar ends will twist first and absorb the impact if they’re tighthen correctly (not over-thightened).

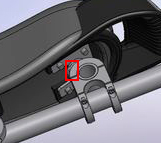

As for your last question, there is only 4 bolts per stem. The middle section has bolt passage holes. The bolts are threaded into the last section. So the two tubes are clamped at the same time. See image :

Yeah I mean, I know about all the points of failure. I know it’s a bit risky but I still want to try it because I have a spare T7 to mess around with ![]()

It does kind of look that way in these pictures. The cable actually connects like this on both ends:

i like the handlebar from vicelemay! i just think the saddle will be to wide in the front for a streched position…

turtle’s V update:

^^^^^^^^^^^^^^

That is my dream machine!![]()

If you redesign the frame a bit so the wheel is further back, you could add another wheel under the handlebars for stability at speed. Perhaps add a chain drive to keep your legs in a comfortable position and… ![]()

Sorry - it’s looking interesting, although those wide handlebars look like they’d be pretty hard to avoid in a front dismount. All these mods are a bit extreme for me (I don’t really do much pure road unicycling - prefer bikes for that), but it’s inspired me to want to try some sort of simpler extended handle on my 36er. Keep at it ![]()

Rob