Ditto here. municycleman, perhaps you are deeplinking to a picture, or linking to something on your local harddrive? If you attach a picture through the “Manage attachments” button there should be no problem.

I suspect it is this:

He posted it on the Facebook Unicycle chat page, and the descriptive phrasing was nearly identical.

" ‘simplicity is the highest form of sophistication’ Leonardo Devinci "

Maybe he over thought this and just isn’t using any bars.

Not knowing how to weld, I tried zip-tieing my scooter’s handlebar on…and that didn’t work too well.

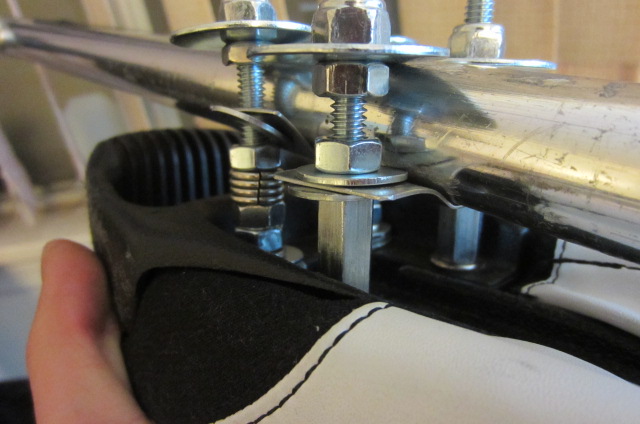

I swapped the grab handle bolts with 3" long ones and used nuts, washers, and 14gauge aluminium plate to sandwich the bar on.

The foam handle grips were dried and flaking everywhere, so I pulled an inner tube over them.

After half a mile…the bar was too loose, so I’ve retightened.

I don’t think this will last, but it’s what I’ve got, and I’m thankful for my parents for paying for my unicycle and the parts from the hardware store.

Hmmm… Wire-feed welders start at around $90 around here when they’re on sale. They won’t make the prettiest welds you’ve ever seen but it seems like learning to use one could pay off over a few projects like that.

I really admire the creativity shown in putting that together, but like you I doubt that it’ll stay tight for very long.

That scooter handle bar is probably aluminum, so it would work with a 90$ wire feeder!

I would drill 2 plates and put them intead of spacers, the spacers will eventually bend and get loose.

Good point! I don’t do scooters and couldn’t tell from the picture. Yes, only for steel at that price.

cool! i guess my christmas gift will be to get myself a wire-fed welder.

I went riding for 10miles yesterday, had to retighten it 3 times…

3d printed two plastic blocks, changed the carriage bolts to 3.5" long ones.

It was difficult to get on because the bolts don’t exit the saddle in the same direction, so I finally decided to drill out the holes to be a little bigger.

The angle is arbitrary (bar goes 10 degrees down relative to the block)

(not sure if I will even get to use this since I ordered a Kh T-bar from udc yesterday)

Is that a handlebar from a razor scooter?

Yes. ![]()

I’ve always thought those would be perfect for home made bars! Glad to see someone do it.

Nice job, Harry!

hello, guys. I’m going to make a handmade handlebar, I need an information drawing of a standard bar. The main info is a position of the bar. In front of saddle or a bit higher? Far or not?

p.s. Sorry for my bad english lol

Depends on what you intend to do.

Big wheel, road riding, the handlebars are likely to be further forward and lower.

Smaller wheel, riding off road, the bar is likely to be closer and higher.

These are only rules of thumb.

Andatraman, as Mikefule says, it depends on what you’re going to use it for. But then again, there are large variations in what riders prefer. There are plenty pictures in this thread to give you an idea.

I would suggest you make your handlebars adjustable. Start not too low and not too far out. Especially for road riding, low-and-far handlebars have to “grow on you”, as they say.

Has there been any further development of this idea in the several years since it was posted here?

While the curves of the version shown seem to allow various adjustments to be made in isolation, I wonder if it would be possible (at least for a smaller wheel or taller rider) to make something serviceable with straight aluminum bar stock. An additional simplification of drilling the sides at a regular spacing (rather than milling) could put the whole thing in the realm of drill-press machining.

Given the seatpost can likely be adjusted up and down and the seat rail clamp in tilt, I think it should be possible to achieve most of the same configurations, at the cost of some interplay between adjustments and the frame ending up slightly off vertical if tilt needs to be used to get a position equivalent to halfway between drilled holes. Or holes in the range of actual need can be selectively “milled” into slots with a hacksaw and file, or dremel.

Another option might be to put a pivot at the forward “elbow” of the strips, and maybe even some sort of turnbuckle type adjuster/brace across that pivot.

This is a concept I truly believe in. If you search unibokk longrider in the search box. You’ll find some interesting discussion there.