So I got my hubs and promptly took the broken one apart.

Hub internals with comments

All hub components.

No grease has been removed from this hub. Like the Nimbus hub there is only a light machining oil present on most parts, with a light grease on the axle where the bearings seat.

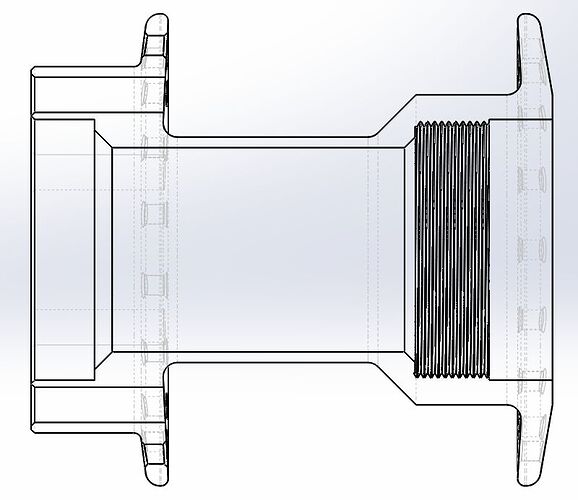

From bearing to bearing, disk to clutch:

12mm bearing, 9mm spacer, 74mm hub shell, 5mm spacer, 12mm bearing - that gives us the standard 100mm bearing spacing, with the axle being 158mm.

ISIS crank spacers should be ~7mm, but this will depend on your cranks and their interface wear.

468.6g excl. ISIS bearings and bolts

592.5g excl. bolts

630.5g total

The three pawls (left one broken), and the broken pawl spring.

The kink on the left of the spring is not meant to be there, only the upwards kink on the right.

The pawls and spring appear to be the same as used for Shimano RS-113 hubs (R0-022X), or Campagnolo 3-FH-RE113 and 5-FH-RE114.

^ This has not yet been confirmed, but I need to buy replacements so I’ll let everyone know!

The pawl spring’s upward kink and the 12mm M15(x1) crank bolts.

The axle (excluding pawls and spring) as it looks when you remove it from the hub. The standard 22x42x12 bearings we’re used to are a press fit on the shaft, whereas the smaller 22x37x9 hub shell bearing is a close running clearance fit on the axle.

In between the two bearings is a 5mm aluminium spacer.

The axle with all other components removed.

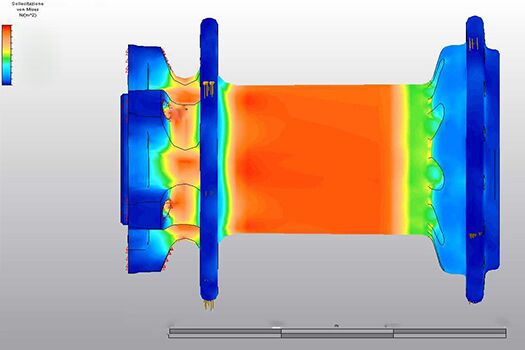

Unlike the JR P-hub, the pawl holder on this is machined as part of the steel axle. With an axle of this size, a much larger clutch mechanism would have been required if it were to thread on. The JR P-hub already uses a larger clutch, despite the axle being 5mm smaller in diameter.

The pawl holder with one pawl installed. The top cut-out is for the kick-out on the spring to locate in.

I do love their logo.

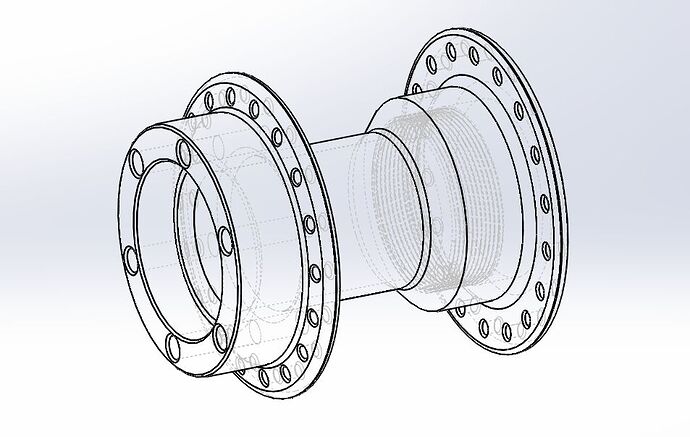

The flanges are slightly tapered in towards the centre of the hub which is nice to see, and the monolithic mount for the disk brake isn’t going to break off any time soon!

On the disk side, the spacer between the two bearings is 9mm. putting the disk interface exactly 15mm from the frame bearing centre.

The disk side 22x37x9 hub shell bearing. These bearings are press fit into the shell and are not trivial to remove (which is why this one is still installed…).

The bolt holes for the disk are entirely threaded through holes to the inside of the flange, so there’s no risk of your disk bolts being too long!

The 24 point ratchet ring. This appears to be a standard 35mm threaded unit, approximately 9mm deep.

On top of the ratchet ring (visible) there is a 35x31.35x1mm steel spacer.

Looking straight down from the clutch side shows that the shell has a large central bore of ~29mm.

With a shell diameter of 32mm, this gives a wall thickness of 1.5mm for the main body.

Unlike the Nimbus hub shell with its notorious splitting on the chamfer, the chamfered part of the hub shell up to the larger surrounding clutch area is almost entirely over the straight bore.

So the broken one requires a new pawl and spring, but it seems like both should be relatively easily available. I’ll confirm when I’ve acquired the right parts.

The ratchet ring is also somewhat marred, but I’m undecided as to whether I’m going to attempt to replace it.

Normal replacement of these parts will be a bit of a faff as the hub shell bearings are not easy to remove, and cannot be removed with a puller (you have to push the clutch side one out with the axle from the disk side).

I’ll post up some reassembly pictures when I get to that point as the process of operations is slightly different to ensure no damage is caused to the pawls.

I’m pretty confident that this hub was broken by someone trying to reassemble it following the bearing coming out, by just pushing/whacking it back in (take note @muni_ben - always use spacers).