It is not needed to use a jbend. You should interlaced two holes with one rope and glue only 2 spokes long 10cm or less to the rope ends. However… what is a chinese fingertrap? An hole covered in glue?

It is basically that the way the cord is spirally braided both clockwise and anti-clockwise, when you pull on it it will tighten up on the spoke inside it, the tighter you pull it the tighter it gets (within reason), it will need some adhesion due to the glue but not as much as you’d think. I didn’t think of that.

You’ll have the same issue there, as one of your bits of threaded spoke needs to be passed through at least one hole on the hub. That threaded spoke will be larger than the standard spoke hole owing to the added thickness of the rope attached to it.

Maybe the easiest way is two very short j-bend spokes, and then a double length braid spoke with a locking eye splice on each end.

No gluing to worry about.

Double length spokes might be a problem though, as unlike a double length steel spoke, it’ll likely move back and forth slightly in the hub, perhaps causing wear and breakage over time.

Tying them around and under each other like they did on Ali’s video is one solution I suppose. At least attaching them to j-bends would permit removal from the hub without cutting the spokes, or disassembling the eye splce too.

Reading back through the MTBR thread it seems that a J bend spoke was suggested and it was suggested that it wouldn’t hold. I have to admit I don’t quite understand the explanation as to why, but I’ll trust them ![]()

PiRope experimented with double length spokes in the beginning and experienced the movement you describe. That’s why they went away from standard hub flanges and use straight pull hubs now. Unfortunately, there are no straight pull hubs for unicycles.

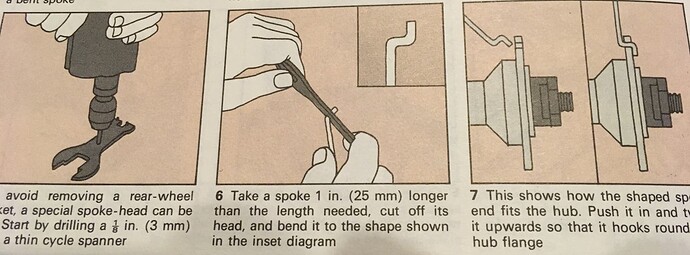

I seem to remember reading something somewhere (a long time ago in days before the web) about having a ‘jog’ in the end of the spoke instead of a J-bend, essentially a kink in the end which you thread through the flange and it ‘hooks’ in when you pull it in line and stays under tension (it might have been in the Jobst Brandt “The Bicycle Wheel” book). It is just like a J-bend but without a head on the end so you can feed just the end in instead of threading the whole spoke through.

I think that would work for this, I’ll see if I can find it in my book.

Which part of the problem would that solve?

I was talking about having a super short j-bend spoke attached at the rim end with a rope loop over the head end. Then you could have a double length tied-around-the-hub spoke to another one.

On the hub, yes I’ve seen mention of a jog somewhere too, which feels like it would work, but I’m not sure how it’s useful here.

Sure, I misunderstood you.

I was thinking of a single length spoke with a ‘jog’ spoke-end on the hub and a short threaded end at the rim, with both metal ends bonded into the inside of the cord as you described. It would mean you don’t need to drill the hub to get the thicker part of the spoke-plus-cord through it – just hook it in, stretch the cord and screw the nipple on the rim end.

Use a longer cable, make it through the hub, cut at the right lenght and than glue the final threaded spoke.

So my memory hasn’t completely failed me – it wasn’t from anything nearly as fancy as Jobst Brandt’s wheel book though, but from the “Reader’s Digest Repair Manual – The Complete Guide to Home Maintenance”, initially from 1972, but the version I have (it was my grandfather’s and I grew up reading it avidly) is from 1981… From the Bicycle section:

They even tell you how to make a tool for bending the spoke from a bicycle spanner!

So, something like this 30mm or so long at the hub end, another 30mm or so long threaded bit of spoke at the rim with a cord glued between them, et voila…

Maybe ![]()

I’ve been building rc planes most of my life and we call this a z-bend, used to attach control surfaces to servos with music wire. There are even pliers that do it for you if you don’t want to fiddle with doing it yourself, but I don’t know if they would work for the gauge of spokes as I don’t have a pair to try it on.

Do you guys think, that a straigt pull hub would be a better solution for DIY cord spokes?

One thing about gluing spokes into the rope is that if you’re in a country where Berd’s patent applies, they’re pricks about it and would really rather you didn’t do it, even as a DIYer (see their post on the mtbr thread).

Although gluing in both ends would not be the same as their patent.

I am very interested in making up a dyneema spoke 36" wheel now, especially as Berd don’t make spokes long enough.

This might be a good cheap source of the material?

Anyone got any clever DIY solutions that don’t involve twisting up spokes and silver soldering?

Maybe a load of these made with a plain 2mm shank in stainless that could then have 14G threads rolled onto them?

Maybe I should enquire about samples.

Maybe slightly, but I can’t see anyone making a hub to suit. At that point you might as well have commercially available cord spokes if the hub’s going to be custom for the project.

That brings it back to me! – a bend like that in a piece of piano wire attached to balsa pushrods and then into the horns on the servos, I had an RC glider a long long time ago – but I digress.

Be sure to round the eyelet very well

I was thinking last night about the Chinese finger trap reference above and that I had something like that but couldn’t for the life of me remember what it was. It dawned on me this morning that I have a few different sizes of these super-grip things for pulling in cables (network, power etc). They are excellent and give an amazing grip on the cable.

Some suitably small stainless gauze like this brazed or silver-soldered onto the spoke-ends with some adhesive might work round any patent issues since it is on the outside (I haven’t looked at the Berd patent). It does seem somewhat of a waste though to add something like that on top of a cord which can do something similar to something inside it.

With respect to the eye bolts – it is just amazing the stuff that can be sourced direct from China! I’ve never really looked for stuff like that, just always looked at UK or US distributors etc. I’d imagine there would be a fairly high MOQ and getting 14G rolled threads instead of cut ones might be problematic for their manufacturing process – however if it is an eye-bolt maybe it isn’t so important that the threads are rolled instead of cut? – probably still best rolled though.

I agree with Eric that the eyelet would need to be pretty rounded inside, just countersinking it might be enough though, that is an advantage of the loop Tarty Bikes have.

I was thinking that if the parts are being made to order, a much rounder eye could probably be specified, and I’d go with an unthreaded blank to be rolled myself.

The blank may well not be strong enough though, being by the looks of it, cast. If I remember correctly spokes are drawn, before they’re cut, the head is formed, and the threads are rolled.

Why roll it yourself while the offer rolled thread?

Naïve question: if it is rope-like material, why not try to lace it in one strand (through the hub then changing hole in the rim…) ? That would limit the “adaptation” needs to tensioning the 2 ends together and making sure there is a way to weave it ![]()

The drawback will be the need to go tubeless (even though a tube may not care about those strands of rope-spokes making bumps). The challenge might be installing the tire with a less shallow well ![]()

To crazy an idea?