Hope this helps:

Q: Could you please briefly suggest any applications of sandwich boards other than those you mentioned?

Q: Do you reckon it would also appear more difficult and therefore be more entertaining this way? It’d probably be more stable too. I can’t pedal grab yet…would you suggest sandwich boards as a good thing to practise on?

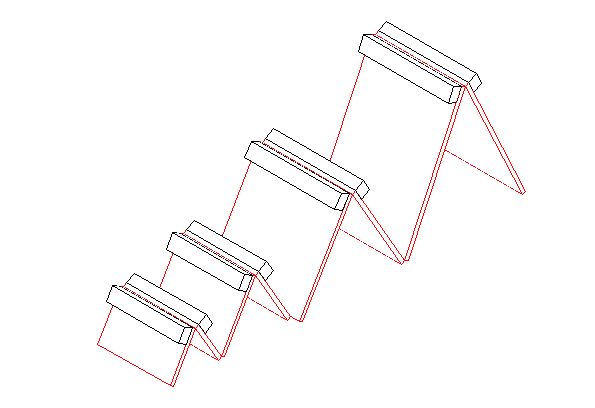

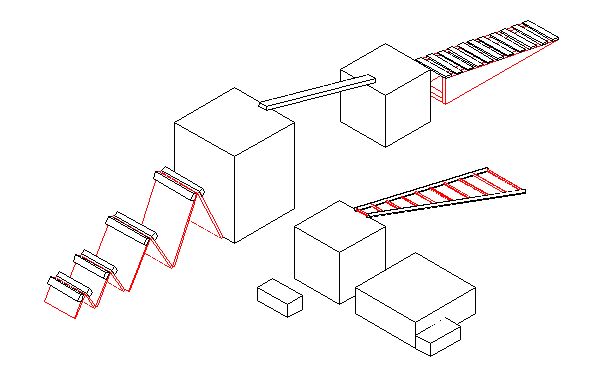

Sandwich boards are one of the best and most versatile pieces of practice structure you can possibly build, because they force you to be a precise trials rider, which in my opinion is way more important than being able to do big moves. You can line them up end-to-end for some good balance lines, or side to side for gapping or any combination of both.

The V-shaped groove makes them a bit weird to ride along at first if you line up several end-to-end, but it’s also a good shape if you want to practice accurate drops down onto a narrow balance lines- the groove catches the tire well and you’re less likely to pop off than a square or rounded line.

Also like I said before you can use two of them for supports for a pole secured between them to create a longer round balance line.

In demos they’re great for linking lines between larger boxes too- crowds always like to see you line up different objectives and it’s easy to mix things up by keeping the bigger structures in place throughout a demo, and dragging sandwich boards around to create different line combinations.

Sandwich boards aren’t as good as standard box structures for learning pedal grabs, but they are a good place to practice more advanced, such as grabs onto the side (for grabs onto off-angle surfaces), or onto the end, where you might have to turn 90 degrees after the grab to ride along it, or go to rubber and then complete a forwards gap to a second sandwich board.

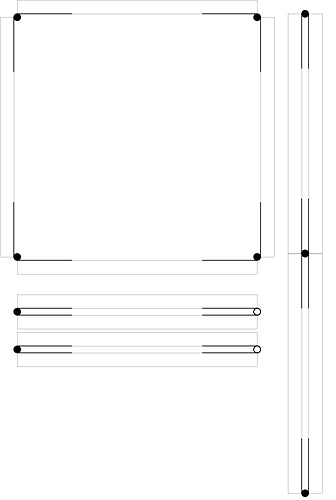

However, it’s CRITICAL that you make the sandwich boards long enough so that they are stable end-to-end for doing things like this (hollowing out the middle of the bottom edge also helps a lot). Ideally, two sandwich boards lined up end-to-end should represent one complete pedal revolution (of a 19" trials uni). This makes it easier to line up your pedals for hops if you land, roll the length of two sandwich boards, and want to hop somewhere else.

Having the 2x4’s on the inside makes the sandwich boards look harder and also they’re a little more comfortable to fall onto for some reason (not that comfortable!).

Q:I just looked back at the ones you guys used at Unicon and noticed the planks extending out at the base of the taller ones. Were they fastened to the ground at all?

This was only done because a few sandwich boards constructed for UNICON were not made wide enough, and this was done to fix this. It shouldn’t be necessary if your sandwich boards are well designed.

You should be able to make rails that nest in the groove on sandwich boards, either round poles or square rails. This is convenient and easily transportable, and can be quite stable. This is a great place to put round rails if you want them.

Q: Great idea. Have you tried this out? If so, did you have any problems with the round rail twisting around in the groove?

I’ve done this where we drilled holes in the ends of the pipes, and then ran a bolt through the pipe and corresponding holes in the sandwich boards. This worked pretty well.

You don’t have any photos of these obstacles do you? I get the general idea but I’d like to see the proportions and heights and that sort of thing.

No sorry I don’t- not too many. However, www.alwaysmad.com has a quicktime video of a trials demo and interview at a consumer tradeshow earlier this year, with myself and Ryan Leech. There’s also an example (hard to see) of dropping from a 6 foot high box onto a 2 foot high sandwich board, oriented lengthwise, and some stuff on a round balance beam.

Demo is at:

Interview is at:

You’ll see some basic stuff in the background, this wasn’t our usual setup.

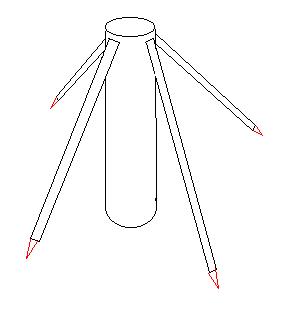

It’s really nice to have a strong, curved transition for drops. Q. What sort of angle would you recommend?..

Curved, not flat, from 45 degrees to gentle over a couple of feet. This depends on the drop height though- a big one like this would be for very large drops. Anything with a bit of angle would be OK. Curved works best but flat is OK, but sure it’s strong enough.

Kris.