My latest build. This one was a lot of fun to make but also the most challenging.

Hope it rides as good as it looks!

Any chance listing pedal mount bearing hardware and mounting info PLEASE?

I just found a dead wheel chair with foot pads and leg supports so now summer here have time to build UW with anti wheel rub system as you make.

I cant zoom enough to see how you get strong axel connection.

I have weaker (age) and fragile knees but mtb and kiteboardhydrofoil and would like to see if I can manage a little UW.

Is 29" rim best and wheel bearing pedal specs?

THX

I will admit I think I will not be able to ride a UW but sure will give it a go!

THX

uk

The pedal/leg support system was modified from a “Lunicycle” I purchased a few years ago. I replaced all vertical plastic pieces with 1/8th thick aluminum flat, secured with machine screws, and also replaced the upper calf cups with longer, much less restrictive pads.

You should paint it a nice yellow to make it look like the sun. Good design! ![]()

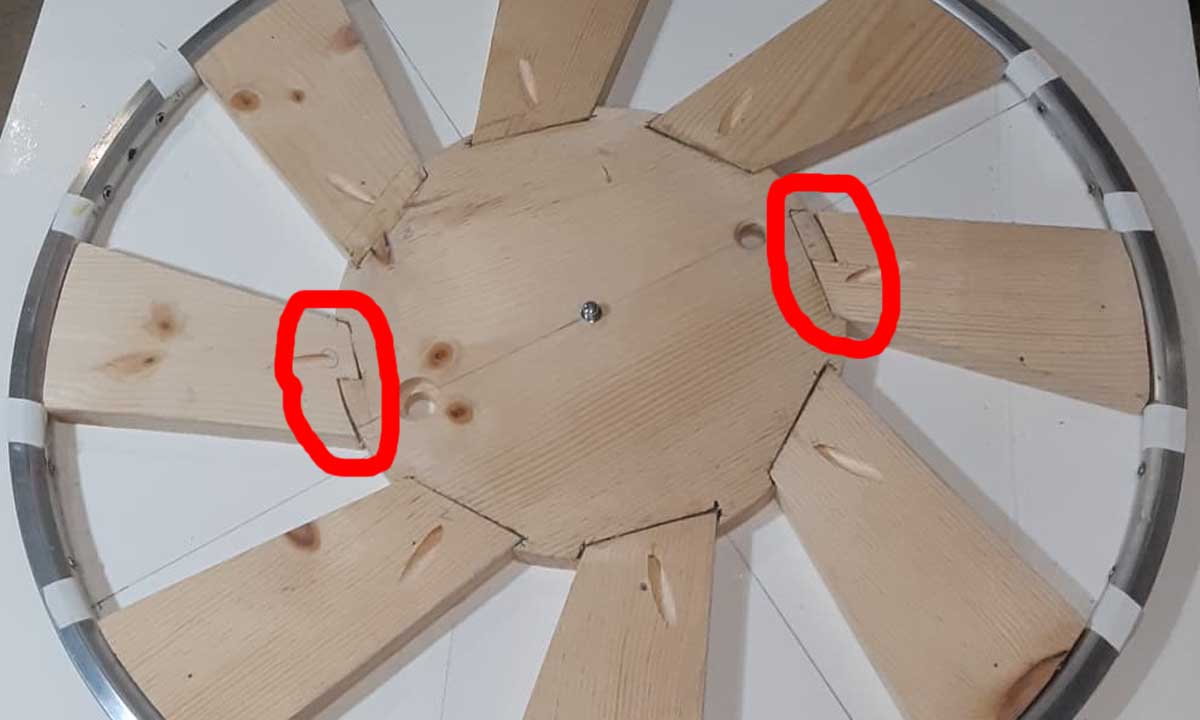

Is there a specific reason for you to connect two of the spokes in a different way to the hub than the rest?

Nice build, by the way.

I was also wondering about this @UniGeezer . How is the central wooden board attached to the “sun rays”. Aren’t they week points, that after a few drops and landing on the pedals, the board will come loose?

@unikyt Like with every of these activities, as long as you put the time in, you will see progress. With UW this will take longer than with unicycling, but if you stick at it and don’t overdo it like I have, your muscle memory will eventually get it. I find it difficult with my heavy wheel to get rolling when holding on to say a lamppost. But if you have like a rail, so you can get a feeling for the movement of the wheel, that will be a great help. At first it will feel strange that you go up and down with your body, something you don’t have sitting on a seat, but you can get used to anything, at whatever age. Just have to be persistent and not giving up.

All 8 spokes are connected the same way and follow the same angle. Each are notched into the central disc and secured with pocket hole screws and tightbond. All 8 spokes help to distribute pedaling forces evenly.

Each of the 8 spokes are notched into the central disc with tightbond and also pocket holes were drilled for each spoke with 1 1/4" hidden screws adding significant reinforcement. All 8 spokes serve to balance and evenly distribute pedaling forces.

But the hub has different cutouts for the 3 and 9 o‘clock spokes…

I’m not sure what you’re seeing, but all the cutouts are the same. Here it is before painting. It’s based on the “nautilus” design. If you rotate your phone in a circular fashion while looking at the photo you should see that the wheel is as stated.

I see a difference in the interface between the spokes and hub in the two spokes adjacent to the pedal connection holes. Maybe to provide a little more clearance and strength between the hole the the edge of the hub.

I think I know what you’re getting at. The reason why those two are notched differently from the others is so there would be room for the plates of the threaded inserts. All the other struts are fully notched in, but 3 & 9 o’clock were notched in halfway to allow room for the insert plates.

How do unicycle shops choose to sell the 24" and 28" UW’s but not 36". The bigger wheel is a lot easier to ride than the smaller ones. I simply don’t have the machinery or engineering know-how to to build them, but am just an end customer riding them. I expect that if they are sold from unicycle.com shop, many more peeps will get the idea to try one. I certainly am hooked.

Yeah, 29 seems to be the largest commercially available size. I think it’s mainly because the market for UWs is already very small, and making 36er sizes would likely result in a lot going unsold and not feasible for a company to make a profit.

UPDATE on my “Nautilus” 29er: Fail! ![]()

6 of the 8 spoke sections that were connected to the central disc by notching, tightbond and pocket hole screws became noticeably loose after just a couple test rides.

I think it was mainly because of the extreme angles of the spokes and also because of the narrow width of the interface of each spoke to the disc, there was room only for one screw for each spoke, instead of the usual 2 on my other UWs where the interfaces were considerably wider, and at perfect right angles to the the main, full-length boards.

Oh well, I may try again, but instead of all the individual parts, I’ll cut out the design from a single, solid piece of wood, and also make the spokes a bit wider where they emerge from the disc.

At least it’s in best hands to get repaired.

Just built a circle cutting jig for my band saw and after a few test cuts it seems to work very well, and much better than my previous circle cuts with my jigsaw jig.

Hey, that’s a really good idea. I would never have thought about that.

@Ulkicycling , to keep the pedal in the wheel of the UW, Ive been using isolation tape

The stuff we also use on taps. This has been holding really well.

To keep the pedal in the wheel? What do you mean?