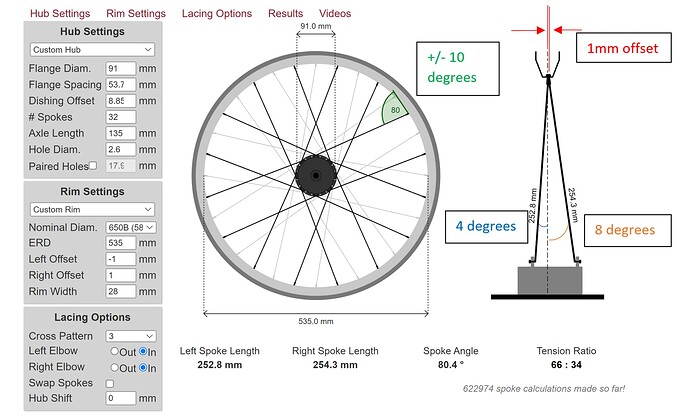

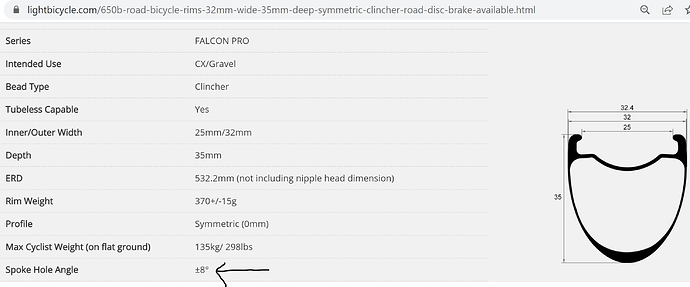

I had thought blue/orange below, which are left/right angles, was what rims are drilled with. IE, the lightbicycle rim states +/-8 degrees.

However, this 32 hole 3-cross build has 10 degrees “rotational” angle. This is more severe than the left/right angle; do rim manufactures drill this angle as well(compound angle?)?

I had contacted lightbicycle about just adding l/r offset (red), and they asked me if I wanted the green angle…?

I’ve never heard of this before, but if I understand correctly it could be good for a thick rim so that the spoke doesn’t hit the side of the rim wall with too much angle. It really doesn’t seem that necessary though.

1 Like

If the rim has been radially chamfered on the inside (tire + inner tube side) the radius on the nipple should accommodate the angle at the rim. Some use eyelets of a slightly larger diameter than the nipple body so it can rotate a few degrees. Others use a washer on the inside with a larger through hole than the nipple body to allow for the angle.

1 Like

I did a quick tour of my wheels, bike and uni, and all of them have the nipples sitting ~vertically in the rim, and the spokes entering at an angle. The worst ones are the small wheels with larger hub flanges, e.g. both of my trials wheels. But even my road bike front wheel, with a 700c rim and small flanged hub, shows it.

So angled drilling seems like an OK idea to me, though I’ve never owned a rim that uses it. And none of my rims have any magic chamfering that lets the nipple rotate a little. Having the nipple pointing straight out and the spoke bending into it seems like it would cause extra stress on everything, spoke, nipple rim. Lining everything up can’t hurt.