I have a wide variety of unusual unicycles but have held off on getting one equipped with a Schlumpf hub partially because of the cost and partially because of my mechanical ineptitude and propensity to break things. However, there was a great deal on a local pickup so I purchased a 29" KH Schumpf on Saturday. I rode it for maybe a minute when I got it then pumped up the tire too hard and burst the tube. I replaced the tube when I got home and rode it for about a mile and then rode it for a little over an hour on Sunday on a bike path. I found it fairly easy to mount in high gear but it’s only a 29" wheel (and I have a lot of experience mounting my much higher geared freewheel unicycle). What struck me most was how smoothly the shifting mechanism works. There was the tiniest bit of play in the hub compared to a regular fixed hub but it was on the order of very slight bearing issues in a pedal. It also seems to be the result of back pressure and I found it to be a training aid to serve as a challenge to use back pressure only for speed regulation and not for balance. Since it’s a 29" wheel high gear seemed most appropriate most of the time but I found it useful to down shift on bumpier dirt sections of the path, to do a tight 180 turn, and to mount uphill. I can think of some trails and rides with either short steep sections or long steep sections where the lower gear will come in handy although just practicing changing gears is fun in itself. I know one issue that people often bring up with a Schlumpf is the weight but I just realized I didn’t even think about this until I started writing up this feedback. I’m sure it’s heavier than a regular fixed hub but it wasn’t different enough for me to even register it. Of course my geared freewheel unicycle is very heavy and I may not be the world’s most observant person. It was really nice being able to go to a bike shop to get a replacement tube (vs. a 36" tube) and probably my favorite feature was being able to have a big wheel experience in a unicycle which easily fits with the other five unicycles I keep in my car so I’ll be ready for most kinds of rides.

I have to ask.

[LIST=1]

A schlumpf IS another car! ![]()

I have found that I’m actually faster on my ungeared 36 with 110s than I am with my geared 36 with 150s around town. Grand Rapids MI… roads are QUITE bumpy from all the winter crapstorms we get, so that play in the pedals makes a huge difference. I can just blast over the bumps full speed with the solid hub. I’m not confident enough on the geared yet to go fast unless I’m very familiar with the road. On a rails to trails, I can average 17 on the geared. Both are fantastic rides. I get the appeal of the 29, but there is something special about just cruising at nearly 20mph on a uni. It’s an absolute rush. Shifting and spooling up while keeping up with the cars accelerating beside you makes you feel like you have wings on your shoes.

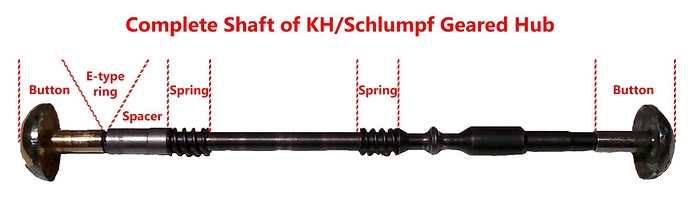

Picture of the complete KH/Schlumpf gearing shaft

Hi all,

In an attempt to participate into building some kind of “knowledge base” (on top of posts such as this one) for whoever might be willing to maintain their KH/Schlumpf hub by themselves (at the cost of losing the warranty of course), here is a picture of the gearing shaft, fully loaded with all the related parts:

Note that I’m not 100% sure yet about the above ‘sequence’, because I’m still working on my hub at the moment, and will only be confident into my “findings” the day I will have built my hub again and get it confirmed that it works as expected!

For instance, the “spacer” has got a thicker end, turned rightwards on my picture. This actually results from a guess on my side more than anything else, as I was not cautious/careful enough to record the leftwards/rightwards orientation of the spacer at the time I removed the shaft…

Also note that, for the same reason as exposed above, I cannot advise anybody to try and remove the shaft from their hub, because I still have to demonstrate that this doesn’t damage any of the hub’s parts. That’s why I am not documenting in this post how I actually managed to extract the shaft from the hub (though the picture itself might be quite self-explanatory about it?).

At the moment I am trying to remove the “real” internal parts of the hub, but even though I removed the 9 screws and screwed in the 3 screws in the dedicated threads to help in the process, I do not manage to extract the “whole thing” from the hub shell… I suspect it might be due to the fact I have not yet removed the C-Clips on either side, something I will be able to verify either today or tomorrow…

Cheers, MadC/Pascal.

Thanks Bouin-Bouin for your own picture of it!

Despite the fact there are indeed a few obvious design differences between your shaft and mine (BTW, my hub is #M0265), I can also suspect now that I may be missing 2 springs on my picture. After I removed the shaft, I actually found 1 spring onto the ground, without knowing its exact purpose - but I could only deduce that it had fallen down from the hub’s internals without me noticing it.

Could it be that there’s another spring that I missed, waiting for me somwhere on the ground?

Quite hard to believe, actually - especially because I am under the impression that there’s still a (damaged) spring inside the hub (if I can trust what I can see when looking -as little as I can- through the hub no that the shaft is removed)…

Anyway, thanks again for your picture, which really helps me visualizing how the hub works… and what I still have to do to repair my own hub!

Cheers, MadC/Pascal.

You could ask Corbin, he dis- and reassembled a Schlumpf hub and also made some photos.

http://www.corbinstreehouse.com/blog/2013/12/geared-hub-troubles/

The one I disassembled “was” M0135 (KH version 1st version with small bearings)

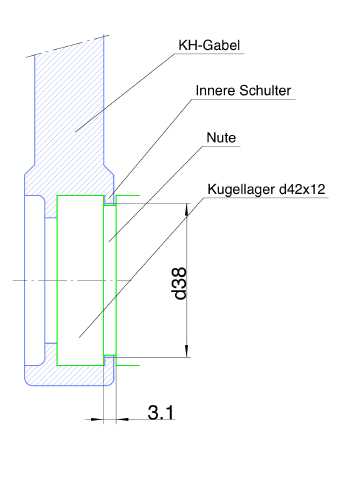

Other view to explain how it works, they are 2 springs on each side of the rod :

My hub that I got used does not have the dust cap on either side of the large bearings, and the knurled side is making grinding sounds. I think it is the larger bearing that is the source, but am not sure.

Anyone have any suggestions? If I were to try to repack it, do I need to be weary of getting degreaser into the rest of the hub?

Should I try to get something to use as the dust cap?

looking for a tuto/video to build a 26/29" geared wheel

Hi.

Il 'm about to join the guni family soon

My first Idea was to find a Sch hub and to put it on my nimbus 29 road unicycle, but the hub will finally come mounted on a complete kh muni 26er, with magura rim brake, kh handle bar, zero saddle and nimbus rim (some of you will guess where I found this Gmuni  ). So this is a good bonus that will let me learn how to ride a geared uni on a smaller wheel than I was thinking about in the first place.

). So this is a good bonus that will let me learn how to ride a geared uni on a smaller wheel than I was thinking about in the first place.

The thing is I already have a 26muni that I’m just starting to enjoy with it’s new kh frame, knard tyre and magura brake, so I will have two kh 26" muni, one non geared, good for real muni riding, and one geared for more rolling trails and urban ride.

Maybe will I enjoy the hell out of the geared 26er, but maybe I will find it more relevant to have this hub on a 29er.

Since, by reading a certain amount of pages of this thread and other schlumpf related threads, I learned that if I decide to put it on my 29" dominator² rim I will also have to buy a kh frame since nimbus frame is not Schlumpf ready, (and maybe will sell my nimbus to have the € to buy kh29 frame and nimbus rim)

This brings me to the first question :

did someone put the schlumpf (muni) hub on a nimbus 29" road ?

The second question is resumed on the title of this post:

I have never built a wheel, only truing some, is there a video or simple tutorial dedicated to the mounting, step by step, of a schlumpf hub on a 29er rim ? (I’m really looking for a schlumpf hub dedicated tutorial).

Sorry in advance if the answer has already been given in one of the 100+ pages of this thread.

Thanks for that.

started to read.

This question is rather destined to Roger.

Is this bearing clamp set compatible with Schlumpf hubs ?

http://www.unicycle.uk.com/unicycle-parts/frames/frame-accessories/bearing-clamp-set.html

If not, is there any way of adding some kind of schlumpf compatible bearing clamp to a nimbus 29" road frame so that I could use my geared hub on my nimbus 29er?

Thanx in advance and sorry if the answer already appears somewhere, haven’t finished to read the 100+ pages of this thread yet.

I think they should work, but if not it wouldn’t take much modifying to get them within spec.

One caution on the housings - they’re CrMo. With aluminum housings, the housing + powdercoat is soft enough that the knurled bearing housing can effectively “bite” into it and secure it against slippage. Even if they fit it is worth using caution for this reason. I’d be interested in anyone’s experiences using a CrMo frame with the KH/Schlumpf hub.

I have a Hunter 36 with Schlumpf (I believe it was one of the first frames designed around the ISIS version hub). It’s got cro-mo housings. I follow the torque spec and have had zero issues with slippage.

Oops, for some reason I assumed they were aluminum.

Dave: Are the insides of your bearing holders painted?

I have put a schlumpf in a Triton (titanium) frame, I am not sure if it was torqued quite to spec but it had slipping issues. I replaced the bearing cap on the knurled side with an aluminum one (MountainUni UCM) which solved the problem…

Hi Eric!

I do not believe the insides are painted. It’s been a while since I’ve had them off. The caps were machined so that they still have a bit of space between the upper and lower caps with proper torque.

I noticed that at proper torque on the (aluminum) KH frame that the caps are really close if not touching.

I know the holders on the Hunter are cro-mo, but I remember it looking almost like they were slightly marked up from the knurling. I can’t recall entirely if this was cosmetic or was actually slight indentations.

From the material properties I remember of reading about Ti and singlespeeds, I seem to remember a different mix being used for horizontal dropouts due to slippage issues. I’m not sure how the Triton fits in there.

I do love the look of Ti.

Powdercoat makes a difference. I’ve had slipping issues where I accidentally had a loose bearing housing, the knurled bearing slipped and ground off the powdercoat (and probably made the bearing housing a bit larger). Also a bit of work to clean the powdercoat out of the bearings.

As a side note, this issue will be resolved on the next model release where we’ve got a better method to secure the knurled bearing side while still giving broad compatibility with a standard frame (e.g. no extra bolts or attachment locations required). I can’t provide details or schedule yet but will keep you posted.