A specific testing setup and equipment would be nice, but I think that with a power meter and some good testing protocols, it should be possible to get some decent efficiency numbers.

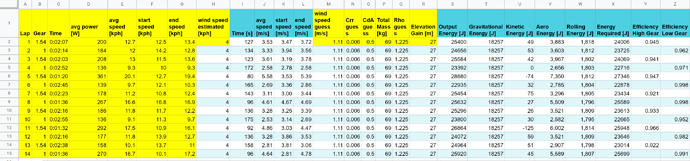

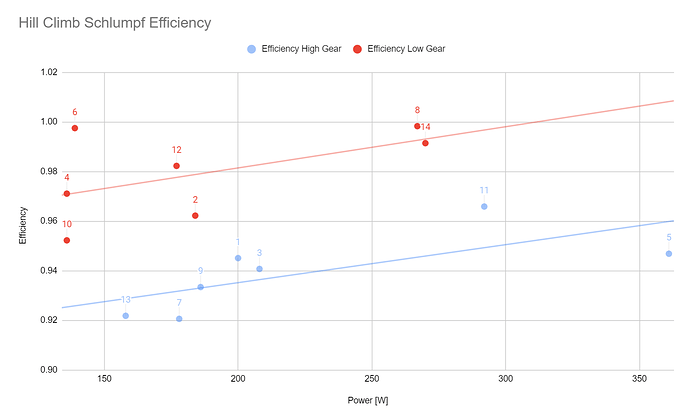

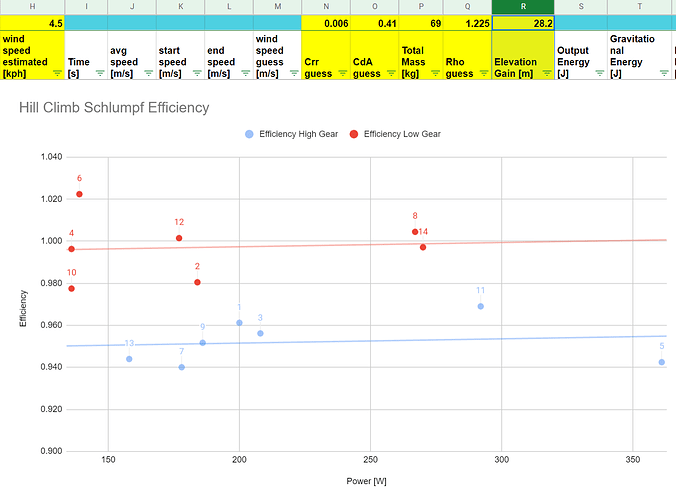

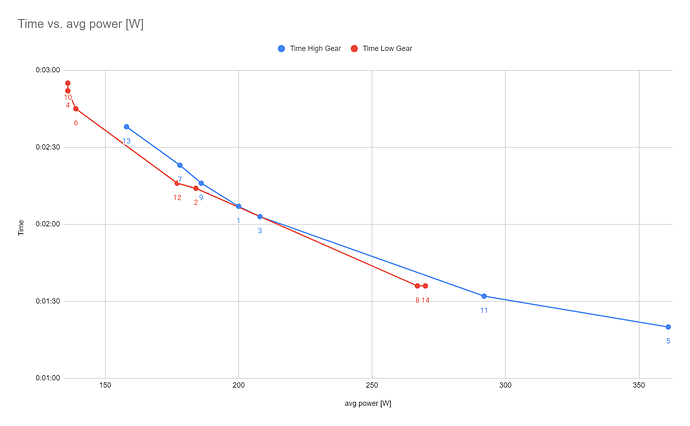

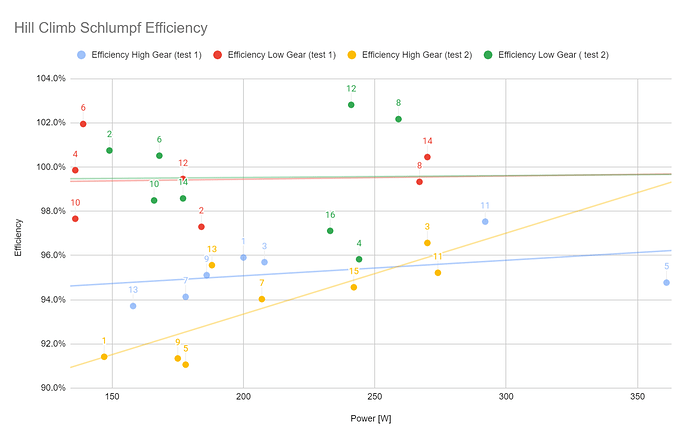

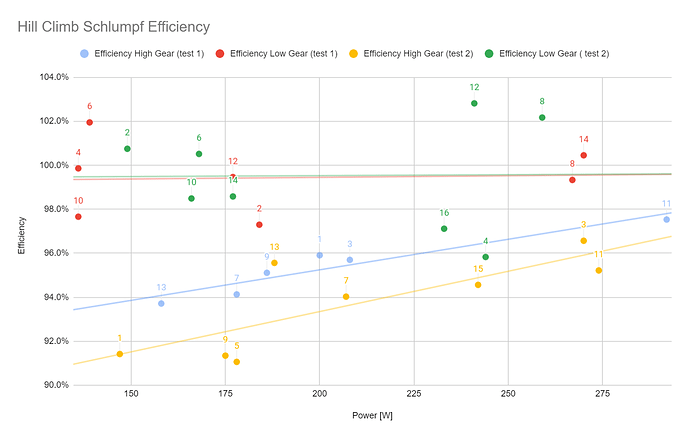

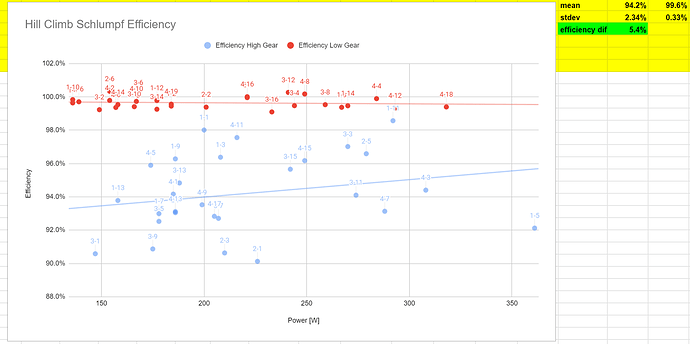

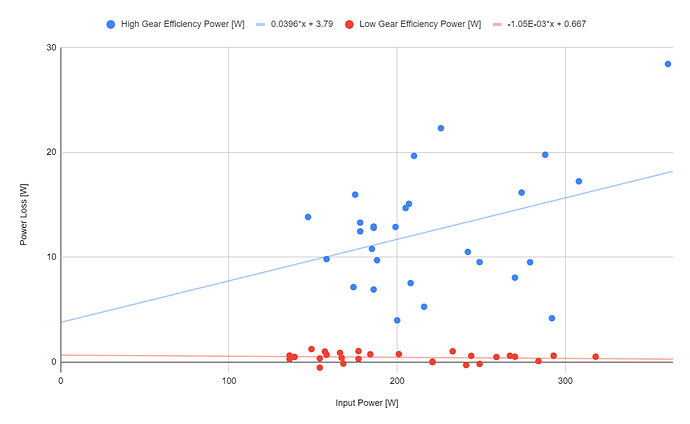

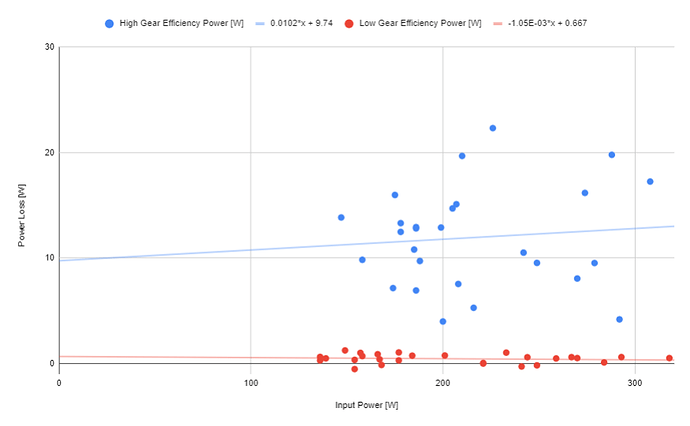

A recent test of mine was to ride a hill repeatedly, alternating between high and low gear, and different speeds/power. I estimated a bunch of parameters, knowing low gear should be approximately 100% efficient.

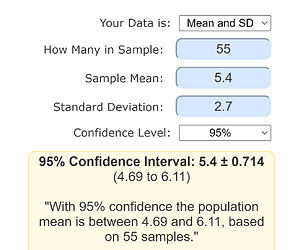

Surprisingly, I think the conclusion is decent! 4% efficiency difference between high and low gear.

Few things I think I can improve:

- Disc brake rubbing. I’m using brakefast, and it was near impossible to true the disc since the brakefast brake arms are so stiff. I think I will try shimming the disc rotor later.

- Wind conditions varied. Strava reported 7.8 kph, nearly perfect headwind direction. But, I have no idea if this was accurate. Choosing a perfectly calm day would be best.

- Hill is short, only about 27m. The strava segment says 30m, but my data points to it being closer to 27m. Unfortunately, this is the biggest “hill” I can get to within an hours drive. Thus, my method of using the strava segment matching may cause some inaccuracies.

- Other coefficients are just my best guesses (Crr, CdA, etc). Some sort of algorithm to estimate these based on my data might be useful.

Would love to hear other peoples’ experiences and insights as well.

Edit:

I dipped my hub internals in ATF recently. Whether that increased or decreased or made no difference to efficiency, is part of the reason why I’m trying to make a test protocol that I can carry out.