From where can a home builder buy machined bearing holders?

Good question. Twice I’ve sawed them off a damaged frame to use in my new ones. But I’d like to get some as well.

Here perhaps?

The shaft collar is the more common option for a DIY machined bearing holder. George Barnes uses a machined shaft collar for his frames. DM used a shaft collar for the Vortex frame. They’re not ideal cause they’re a little heavy for what you need and some can be a bit thin where the bolt head is countersunk meaning that there can be very little metal supporting the area under the bolt head. Depends on the make of the shaft collar.

Here’s a thread that talks about bearing holders.

Steve Howard has also used shaft collars for his steel unicycles. Here’s one thread where he talks about his stainless steel muni project. Steve’s gallery has pictures of the shaft collar being machined but the gallery is down right now so I can’t link you there. Steve’s main gallery page is at http://www.unicyclist.com/gallery/showard

In the UK I use Farnell for some personal orders. As I can’t read Swedish I don’t know if this option is available to you but here is a link to a 40mm 2pc collar:

http://se.farnell.com/jsp/endecaSearch/partDetail.jsp?SKU=3471883&N=401

It seems very easy to buy shaft collars over the web in the US, and other metal items, but very difficult in the UK.

Regards

Keith

Slip without a lip?

Thanks for all the good links. Through them I managed to find a dealer even in my home town!

I wonder why people have found it necessary to bore out a lip preventing the frame to slip radially on the bearing surface. These collars seem to be made for industrial use - won’t they clamp tight enough not to slip without a lip?

Re: Slip without a lip?

You don’t want to clamp it down too tight as that will make the bearings move less freely and will also wear out the bearings quicker. Though that’s probably less of an issue with good machined bearing holders.

I haven’t measured the torque used however I tighten them with a ball ended allen key (screwdriver style handle) and I doubt it is any higher than with the standard pressed bearing holders.

Saying that I generally braze a small lip of steel on the outside of the shaft collars, this is easier for me than getting undersized collars and boaring out to leave a lip.

Keith

Re: Re: Slip without a lip?

With an ID of 40 mm (equal as the bearing’s OD) I believed the shaft collars couldn’t be tightened so much that they prevent the axle from rotating freely …

The brazing solution did cross my mind but then I suppose you’ve got to find a collar that is not too wide, just a fraction wider than the bearings.

So you think it is enough having a lip only on one side (the outside)?

I saw that some collars have grooves on the inside. Find a ball bearing with similar grooves on the outside and we could pip the lips …

Re: Re: Re: Slip without a lip?

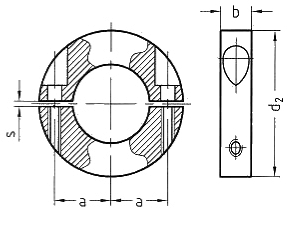

Although the inner radius is 40mm the two parts do not make a complete circle, if you put both parts together and measured the distance from wall to wall you would measure around 37mm. To explain without drawing a picture imagine they made a single collar ID 40mm and then cut it in half with a 3mm wide saw blade.

This clearance means you can easily overtighten & crush a bearing.

So far I have either ignored the lip or brazed on the outside only, this makes it much easier to align the wheel during assembly. On my first frame I did suffer from a little slippage hence adding a lip.

Re: Re: Re: Re: Slip without a lip?

That does sound a bit discouraging. On my 36" wheel (which is what I plan to build the frame around) it is hard to find out how hard to tighten the bearing holders. The heavy wheel is not a sensitive indicator and it is easy to overtighten, I have noticed.

Would this work?

Instead of welding/brazing the frame tubes directly onto the upper bearing holder you weld them onto a 3 mm steel plate which you use for bolting a (stock) bearing and its house (plummer block type). Such housings can be found in aluminium or polymer. The bolts could perhaps be of QR type.

The benefit would be having a proper bearing housing that is not giving any slip or flexing. Haven’t found a suitable one yet though.

Re: Re: Re: Re: Slip without a lip?

I found the illustration for you ![]()

The inner diameter of this collar is 40 mm when ‘s’ is 2 mm. I believe you would be able to fine tune this measurement with help of washers so that tightened the clamp provides a sufficient hold without deforming the bearing.

And, why not put some red lockite on the lower part of the collar?

All to avoid the trouble of making a lip …

Re: Re: Re: Re: Re: Slip without a lip?

I would think you could do a machined collar like that up very tightly indeed before it would deform the bearing, as the case of the bearing is supported almost all the way round. The cheap pressed bearing holders are quite bendy and really only grip the bearing at two points (top and bottom) so the middle could spread quite easily.

Do people who are using machined bearing holders/collars get much problem with deformed bearings from overtightening?

Re: Re: Re: Re: Re: Re: Slip without a lip?

I am not sure I agree with you. Take another look at the illustration. The bearing that goes into that collar has a 40 mm diameter. This is the same diameter as the opening of the collar as long as the distance between upper and lower half is 2 mm (where the bolt holes are placed). If you tighten the parts so they go against each other the hole is no longer circular and the diameter will be less then 40 mm.

So depending on how strong the collar is and how much porridge you ate as a child, you could squeeze that bearing inside the collar to be oval. Placing washers on the bolts between the two collar parts might be a way to adjust the squeeze to perfection …

Re: Re: Re: Re: Re: Re: Re: Slip without a lip?

I sincerely doubt that would be a problem; I doubt that you could actually deform the bearing by hand with that holder.

That said, a while ago I came up with 40 ft-inches (same number as cranks, different units) as a reasonable torque for the bearing holders.

This comment applies only to the nearly-completely circular type, not the main-cap type of bearing holder.