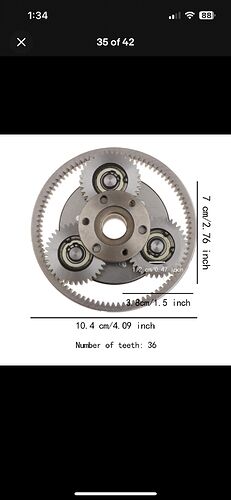

Ok it’s time for a big and tough project, an electric assist. So Marty here has a 49” ultimate wheel and to make the spokes he made threads on both sides and put one side into the 49” rim and the other into a smaller rim. I’m going to take this EUC motor and drill spoke holes in the rim and use double sided spokes. Next a freewheel that catches forwards going from cranks to rim (bypasses motor for 1:1 when motor isn’t used). Next an adapter is made from ring gear to the inside of the motor is made and an adapter from planet carrier to unicycle hub flange so pedal torque is reduced when using motor. So you may be asking: “well if all parts of the hub are spinning then how is power supplied?” Power is supplied by a hollow bore slip ring with one side mounted to the frame, this allows everything to spin freely while allowing electricity to flow, which means that the stator now rotates. If you pick up a hobby motor you will see that the stator is the shell, if you rotate the whole motor by the shell you will notice that the rotor (metal rod in the center) will stay in the same position. If you power the motor then the rotor will spin, but if you rotate the whole motor while it is powered the the rotor will spin at the same speed relative to the stator but relative to your hand it will spin at the same speed plus the speed that you turn the stator. Because our electric hub’s stator rotates this oddity gives us the ability to remove a speed or torque sensor for assist level. If we power the motor and spin the cranks at the same speed but backwards then the rotor in relation to the frame will stay still, if we spin the cranks at the same speed as the rotor and I. The same direction then the rotor in relation to the frame will be twice as fast, so any corrections we make will still be applied through the wheel without any extra pieces or sensors, it also acts as an electric CVT of sorts. Now we move onto control layout. A simple twist grip throttle under the seat for applying power is enough for most people, but I am a forgetful person so I would forget to turn it all the way down when I dismount, and dont forget about UPDs! We do t want the uni running away from us if either of those situations happen so I propose a proximity sensor mounted to the leg via a strap of some sort that has a range of maybe 1’ to 6” or so. When the sensor leaves range the motor will stop. I am researching parts to use for this but there’s no guarantee I’ll ever build it. I’m putting it out there as a community project

Hi, I red it several times. Is this post a joke?

If it was wrote at April 1st. But now is not April 1st…

Archimedes said: Give me place of stand…

You don’t need a point of stand?

Every motor should to have the point of stand on the frame.

It is exactly what I wrote, it will be a unicycle that uses an EUC motor as a hub, the pedals still need to be used for balance though

I was thinking of Justin’s video when I saw this thread – the unicycle in the video you posted looks a lot more manageable than Justin’s prototype – which looks like it would lead to a guaranteed trip in an ambulance… for me at least ![]()

I think I’ve seen a few other videos of his development of this but I can’t find them just now.

just curious, I understand you can ‘simply’ build such a wheel with spare parts and some welding, but how or where can you acquire such a big tire. Is it a solid tire or something with air in it?

Also do yous have a video of it being ridden. The diameter must be for peeps with extra long legs.

No really, it is only 49 inchs. My penny farthing has a 54 inch wheel. For perspective @rogeratunicycledotcom rides a 50 inch penny and while he is a great guy and insanely quick, he is … umm, not the tallest guy. Don’t hate me Roger! ![]()

ok there is some space above the wheels with my 36" uni and UW, so I suppose you can get bigger. 49" seemed like a lot bigger. What size cranks would you ride with a 54" Penny?

IIRC he used 89mm in that picture I just edited in above.

EDIT: Sorry you meant me. For riding around Oslo, which is hilly (and I am in no rush), I use 150mm. When I was racing Roger told me (well… almost inisisted) I had to have shorter, so I dropped to 125mm.

no I didn’t mean you. I meant in general. But now I know 89mm for short peeps and 150mm for taller peeps ![]()

I think he runs those shorter cranks for speed. I should probably have gone shorter than 125 as well I presume but these were dual hole with 125 as the other size, so it was an easy option. In addition, I had never dropped crank size before on the penny, so did not want to go too extreme right away.

So rather than say 150 for tall people and 89 for short I think it is more, 150 for cruising and shorter for speed.

naturally, I wasn’t very serious. I am aware that speedos want the shortest cranks. With the 140s I realised at some point it, that it was more relaxing for me with the 150s. I had put the 140s on the 32". But if Im gonna get 125s I will try them on the 29" first. I really need to focus on free-mounting and instead of taking off right away stay upright a moment first. That will help with shorter cranks.

Yesterday I had the prob that the left pedal was too loose and wouldn’t stick in the right position when mounting. So it was securily attached to the crank, but the plastic pedal part was loose on the centre bar, if you know what I mean. Anyways this gave an unpleasant wiggle when I got on the uni and took some getting used to when mounting.