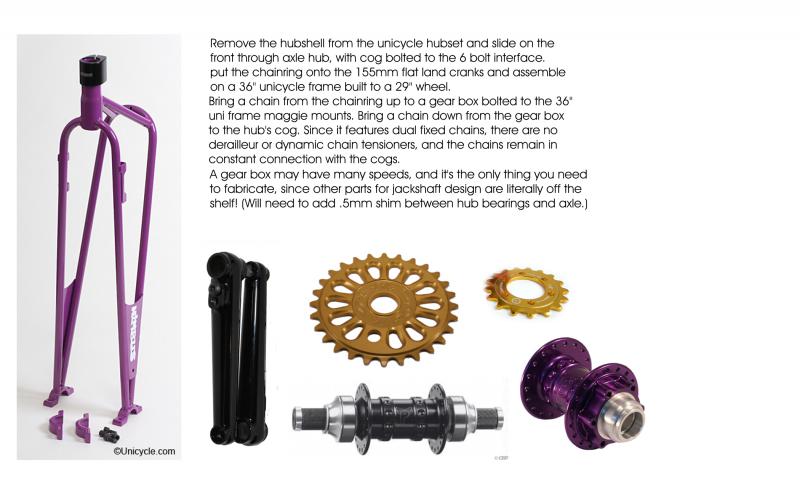

Imagine a chain from the chain ring to a gear box above the wheel, and another chain from the gearbox down to a cog on the hub on the other side of the wheel. I would prefer belts, but this stuff is off the shelf. Now to fab a gearbox.

you will not “derail” chains with derailleurs and tensioners, so your drivetrain will be safe in both directions and while shifting, and the person is not displaced further above the wheel like on a penguin. Done.