i used an old piece of tube and a good amount of shoe goo with a little spot of duct tape. ill see how it goes from there after it dries overnight

Yes this is an old thread, but I didn’t want to start a new one (recycle!). Anyhow I’m trying to ween as much live out of my 24x3 Nokian Gazz. as I can and I’ve had this odd side-wall slash for quite a while. I have no idea how this happened, but there is a perfectly straight, shallow, slice across the sidewall that is perhaps 8" long!!! I’ve ridden like this (not everyday mind you) for perhaps over a year w/o any problems, however I can see the threads/cords of the inner tire layer. Note there is no “hole” through the tire, yet, just superficial damage. I was wondering if this could be “patched” somewhat by sewing up the gash and if so, how and with what? Keep in mind I’m milking this tire along for as long as I can… I was thinking some sort of a fishing line stiching might be in order? Anybody else experiment with this?

I’ve never heard of anybody sewing up a tyre sidewall, but I suppose it might work (and would probably look quite cool as well if you did it with contrasting coloured thread!). I would think you’d be better off glueing a patch (perhaps from the sidewall of a dead tyre) on the inside.

Rob

Try some staples.

It sounds like the casing is okay, just the rubber on the outside is having a problem. Maybe something like Shoe Goo could help hold it together?

If I understand correctly the slash is through the rubber of the sidewall, but not through the threads? If that’s true then there is something called “tire life” that is made to refresh sidewalls on sewups. I have used it to do spot repairs on clincher tires and it works pretty well. It is really just liquid latex. It is probably not too different than Slime. You brush it on rather than filling your tire with it.

As for the old thread that this stemmed from: there are tire patches that are really just canvas with butyl rubber on one side. You apply them to the inside of your tire in the same way you apply a patch to a tube, and they work very well. We used to sell tire patches at the bike shop I worked at, but that was a long time ago.

Right, there is (as far as I can tell) no damage to the underlying threads it’s just the outer rubber layer has been rather neatly sliced right down to the thread layer. The resultant “gap” has remained about the same size for a while, but I’d like to patch it up before things get worse… So my issue I guess is with the outer surface to patch up rather than anything internal. I’ll look at that “tire life” product as a start. I might actually have some Shoe Goo as well to try? Why not?

Shoe goo may be better than tire life for this kind of repair. I would just make sure the rubber is clean before applying so that it doesn’t peel off.

Rather than just use Shoe Glue, I would suggest gluing a patch over the cut. You will need a glue that adheres to the both rubber tire and the patch material, and then a strong patch material. Shoe Glue might be fine for the glue. Patch material could be a piece of an old tire (sidewall) cut to size. You would want to keep it as thin as possible and bevel the edges. You could also use high tech material like kevlar tape or maybe just nylon cloth–that would be very thin. I would patch it from the inside.

A lifetime supply of kevlar tape:

Scott

maybe a piece of rimtape under it with duct tape holding it shut

What’s the meaning of your ‘white power’ tag line, Howdigetsogood?

I damaged my 36" tire the other day while riding on some sharp frozen gravel. With about 2000 miles of tread wear left, this is what I did. So far it is working well but does bump a little on each revolution because of the less flexible section.

The old tire section I used was from my 50 year old 24" uni.

Park Tool does sell tire boots made for bike tires but I did not have one.

I would have just cleaned it up and put a square of good quality duct tape in there at a 45˚ angle. It could be argued that a 1/4" hole wouldn’t need anything with a standard tube.

In this case with a standard rubber innertube it did push out enough to wear a hole in the tube. Also there was a noticeable knot or bump in the surface of the tread. My original thought was that the tire was totaled but I will see how it holds up.

Back in the day (or at least in the 1980’s  ) puncture repair outfits/kits used to come with a ‘gaiter’ you could glue into the inside of your tyre for such problems, a bit like the Park boot you linked to – it just came in the little box with the patches, sandpaper, rubber solution and bit of chalk.

) puncture repair outfits/kits used to come with a ‘gaiter’ you could glue into the inside of your tyre for such problems, a bit like the Park boot you linked to – it just came in the little box with the patches, sandpaper, rubber solution and bit of chalk.

Being at school at the time and wearing bike tyres down to (and through) the canvas, and having no money to buy new ones, I used to resort to fixing the 1/2" holes in the centre of the tyre with bits of an old tractor back wheel inner tube. That gave the ‘bump’ you described and basically caused the tyre to wear more where the repair was, thereby exacerbating the problem. After a few miles you’d get an ‘egg’ sticking out of the tyre and shortly after a familiar hissing sound… Hopefully you won’t get that happening with your repair, your tyre still looks in reasonable condition and you’ve got a pretty substantial patch inside.

I got fairly adapt at removing and refitting tyres back then though, and also used to walking home!

Nowadays, in the twowheelers world, they would plug the hole with a small mesh using an application stick (to ram it in the hole) and let the tubeless sealant does its magic (as it plugs yet remains flexible).

Going tubeless on a 36 with parts not designed for tubeless is an adventure in itself. However just using one of these tire plug mesh (as sold in all physical and virtual LBS) may be an interesting technique to try and then pour delicately from the outside and inside some sealant/goo/whatever latex-like liquid to plug it.

Let’s see if the next thread necromancer uses this technique or yet another one

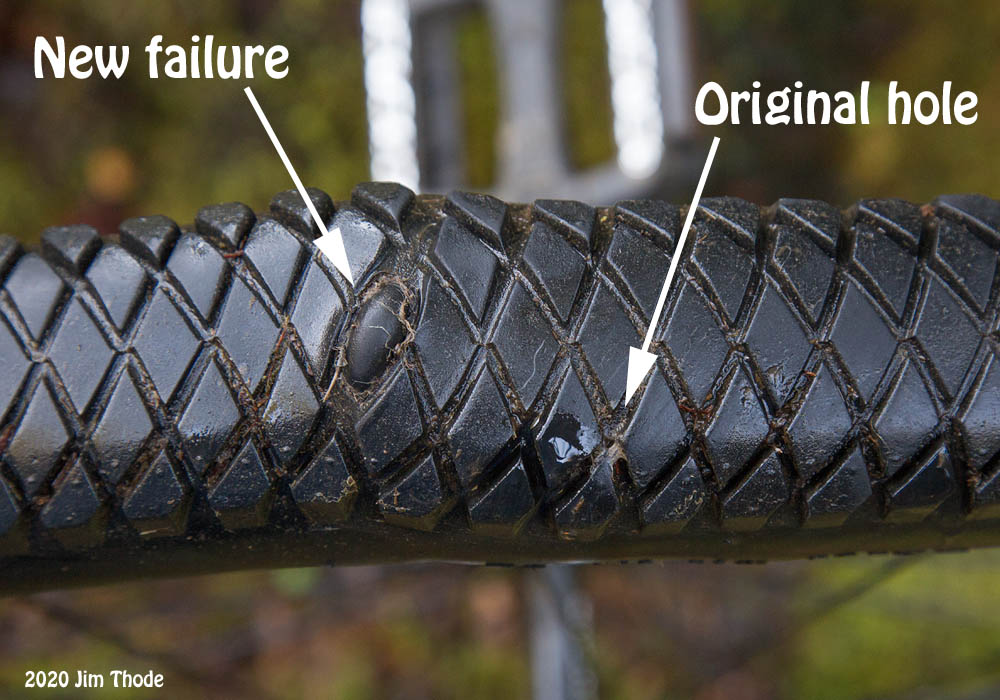

My repair lasted about 20 miles. 10 on the road that seemed to hold up well but 10 on gravel with constant turns did it in. My original patch held but It failed in a new location adjacent to the patch.

I’m now looking for another tire but can still ride my Coker in the meantime.

I would bet you @rogeratunicycledotcom would like to have a look at that tire. This seems very much outside the norm.

Interesting repair. The carcase weaves have been cut. I believe that it is unwinding itself as you ride, hence the other failure. You can sometimes trace where the inner carcase weaves go from the inside, possibly you can see one leading from the first failure to the second. I have not seen anything like this before. A cut through a tyre like the first would often be the end of a tyre and require replacement.

I’m thinking that the second and fatal problem was caused by an abrupt change in casing flexibility between the area that had the boot and the original tire. The area of the glued in boot was quite stiff. The second problem was exactly at the edge of the first repair boot. If I had a boot that tapered down to very thin edges, it may have worked.