Well, I have successfully built a recent Schlumpf wheel (but with different rim and with the 125mm hub). You don’t need to go to a calculator web site - you can simply plug some numbers into a formula and paste that into a google search and it will do the calculation for you.

The formula (for a standard cross 3 lacing with 36 spokes) is:

L = sqrt(d^2 + r1^2 + r2^2 - 2*r1*r2*cos(pi/3)) - r3

However, if you have a different number of spokes than 36 (but assumed to be an even number, same count each side), then use the following formula:

L = sqrt(d^2 + r1^2 + r2^2 - 2*r1*r2*cos(4*pi*x/n)) - r3

here x is the number of crossings (e.g. 3) and n is the spoke count (e.g. 32).

the other symbols have the following meanings:

d = offset along from axle center to flange

r1 = flange radius to spoke hole midpoint

r2 = ERD/2

r3 = flange spoke hole radius

So, to explain these in more detail:

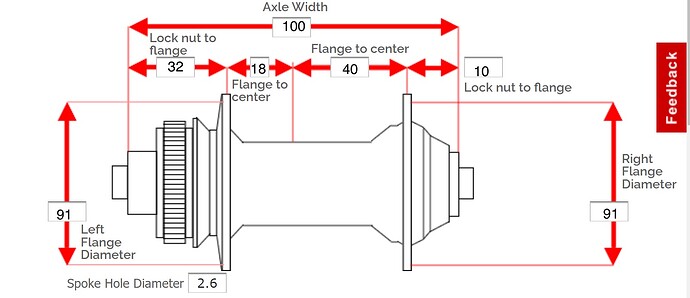

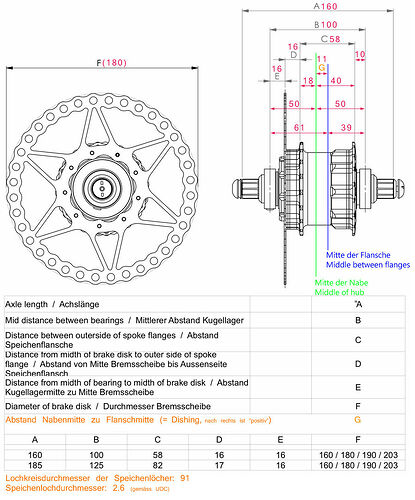

d assumes that the rim spoke holes on your 29er rim will be in a plane which intersects the axle at the midpoint between the 2 bearings (in your case 50mm from each bearing center). The actual hub flange on one side has an offset from the bearing of 10mm, so its offset from the center plane is 40mm. The other hub flange (disc side) has an offset of 16+16 = 32mm from the bearing, which means its offset from the center plane is 18mm. So, d will be 18 on the brake side and 40 on the non-brake side.

r1, I believe is 45.5mm, assuming that your hub flanges have a distance (on each flange) of 91mm between the centers of opposing spoke holes. You should check this on your actual hub.

r2 is 300mm, assuming the ERD is 600.

r3 is 1.1mm, assuming standard gauge spokes.

substituting these numbers we have 2 formulas (for 36 cross 3):

sqrt(18^2 + 45.5^2 + 300^2 - 2*45.5*300*cos(pi/3)) - 1.1 =

sqrt(40^2 + 45.5^2 + 300^2 - 2*45.5*300*cos(pi/3)) - 1.1 =

just copy and paste a formula into the google search bar to get an answer.

when I do it (using the above numbers, which you should check) I get:

279.5mm and 281.8mm which is much closer to the UDC numbers.

But if 32 spokes is assumed, we need to use the other equation with x=3 and n=32…

sqrt(18^2 + 45.5^2 + 300^2 - 2*45.5*300*cos(4*pi*3/32)) - 1.1 =

sqrt(40^2 + 45.5^2 + 300^2 - 2*45.5*300*cos(4*pi*3)/32) - 1.1 =

to get 285.2 and 287.4 which is closer to the other calculators.

Extremely minor inaccuracies can happen due to assumptions about the nipple, the exact center line of the spoke, the spoke tension stretch, and the ERD. Of these, the ERD is the biggest worry (do you trust the rim specifications, or do you measure, using your spokes?).

Spokes will stretch a bit under tension, but this is not much. If a bit too long, it is not critical if the rim has a double wall. If you are getting the spokes cut, you may be able to ask for the threaded section to be a tiny bit longer to minimize nipple threading issues.

Good luck with your build.

NOTE: I edited this post to cover the case of 32 or 36 hole rims, as I guess some people will choose the new option of a 32 hole hub which might give a greater range of bicycle rims to choose from.

![]()