Here are Kurt J. Lesker’s machined SS KF clamps. I’m sure Varian and Huntington have variations of the same thing but I buy mostly from Lesker so I’m familiar with them. I thought the clamps we have are cast or formed SS but, as I said, I’ll check tomorrow.

Oh! Those aren’t cheep!

Thanks Greg - I was a bit worried about the welding too. Also don’t know what kind of AL it is, 6061 would be ideal, then it will heat treat.

I have seen the SS wingnut variety of KF clamps, it may be possible to retro-fit the spring assembly onto a SS clamp if it is the right geometry, it would just require another hole and spring pin on the lever of spring side.

How about that? All I could find on any of the apparati or in the spares or in the vacuum leak detector supplies were aluminum clamps. I always thought they were stainless. Well, at least you know Lesker supplies stainless KF-25 clamps.

How about making the lower cap it’s own lever, that way it could provide some additional leverage?

OR

Have a lever either side, so two time 90 degrees.

Personally I’d like the lower lever design for it’s simplicity and leverage, though that lever would need to conform better to the shape of the bearing cap.

How about designing the lever as a “grind” pad, this way it would be burly enough for muni. In most cases folks wouldn’t really have an abuse problem in muni since we’re not grinding as much as park riders. My lower bearing covers are all pretty fresh looking…

The best part would be if somene could design a quick release that would work with the existing frames, i.e. buy a quick release bearing cap. Think of it as having a hinged bolt on one side, the other side is a bolt with a lever, the cap is slotted on the lever side for “unclipping” the cap.

looks very cool and slick, I just finished my qr clamps for my stainless steel 29er. some pics are on my profile

Yes, I have kicked the crap out of them over the past 5 years. One of the sets I have used has endured the following:

-Up to 9 foot drops to flat ground

-Outlived a profile crank arm and a KH crank arm (both 4130 chromo, one has a lifetime warranty)

-Outlived a GB4 stiffener plate

-Outlived a KH rail adapter

-Outlived more pedals than I care to count

-Survived all around abuse and punishment while riding muni

I bring this up because we still have a couple pairs of these things floating around in the garage from years ago waiting to find a home. Message me if you’re interested.

With disc brakes becoming so popular, a quick release bearing cap would be very useful, since you could switch wheels on you MUni and keep the brake without any hassle.

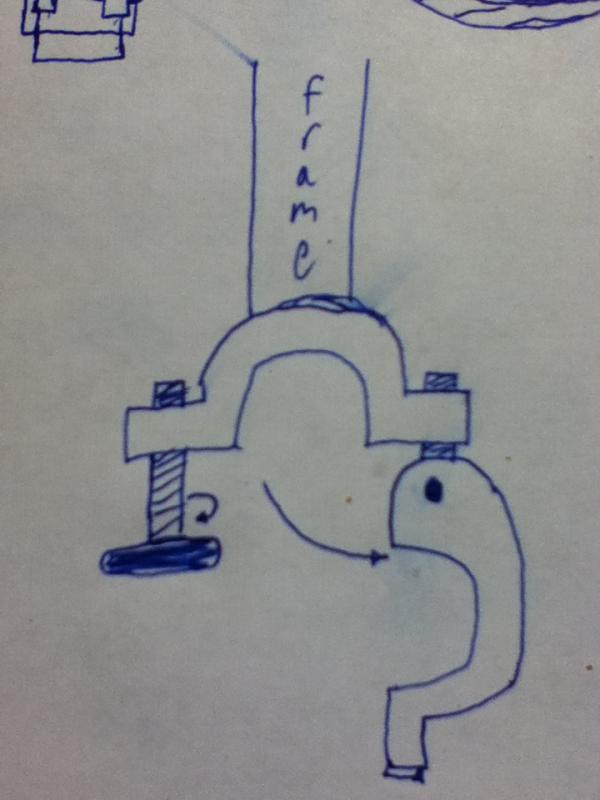

I just thought of something while I was clipping my fingernails that might work for any existing frame without modifications. The only thing that I am concerned about is the strength of the hook on the left. Maybe somebody has a better idea on how to connect the lever to the left side of the cap. The idea is that you leave the right side screwed in at all times. there is a hinge on the threaded side of the cap that allows it to hang down, so you can tighten/loosen/uninstall it. on the left side, there is a hook that goes through the existing hole in the frame. That hooks onto the QR lever on the other side, similar to fingernail clippers. Then, you can flip the lever up, and the cam locks it into place. This could even be used with the new disk break systems if the caliper mount was built into the frame.

The only bad part is I have none of the resources required to make a prototype for this.

What do you think? (I apologize for the poor drawing)

I just thought of a stronger way to attach the quick release lever:

![IMG_1619[1].jpg](https://www.unicyclist.com/uploads/default/original/3X/e/5/e5405476d7977f3cb63ea8e8022c4516321518bf.jpeg)

You’re onto something there - but surely you’d be far better off having it the other way up? Given the bottom bit is totally custom, wouldn’t it be easier to have the QR bit there?

+1

I’ve been thinking all day, why cannot we have top part as it is and bottom part that contains QR. Of course that makes grinds impossible, but QR is not for grinding anyway.

Quick release on the bottom would stop pretty much anyone who wanted to do trials/street etc from using them but so would quick release on the top as it’d fall apart every time you hit it on a bad landing of a trick.

I don’t think making it incompatible with trick based unicycling would be a massive issue. On the KH and other frames you could then use the threaded part to attach into as well.

I’ve been thinking about something like this, with U shaped hole in QR side of bottom bearing. But as the screw cannot move in the upper part, then it must be something elastic instead of the screw.

But maybe it would be easy enough to open the QR and unscrew it totally on one side. I think it would be much quicker than current solution anyway.

I have an idea for QR on the bottom without needing to unscrew anything - just need to do some drawings…

You don’t need to unscrew anything with these drawings. The bearing cap is hinged, so you just swing it out of the way and leave it attached. That way you don’t even have to deal with taking it off.

Yes - but I’m talking about a QR on the bottom. There are some fundamental issues with doing it on the top the way you are, relating to the size of rod you can use to fit through the existing hole, the weakening of that thin rod to fit the cross rod (I’m less than convinced there is then sufficient material at that point), the use of part of the frame not designed for it as a bearing surface for the QR and the limited range of motion of the QR. All of which can be improved by having the QR on the bottom where all parts are custom.

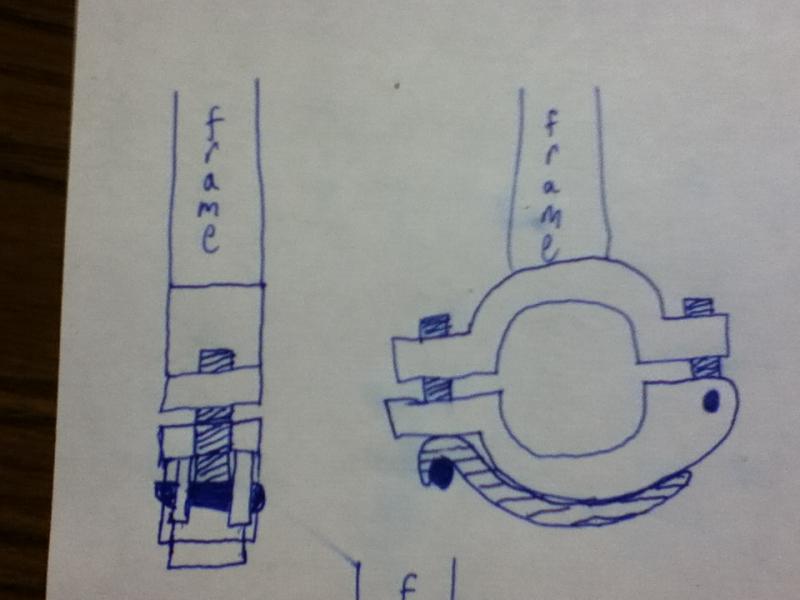

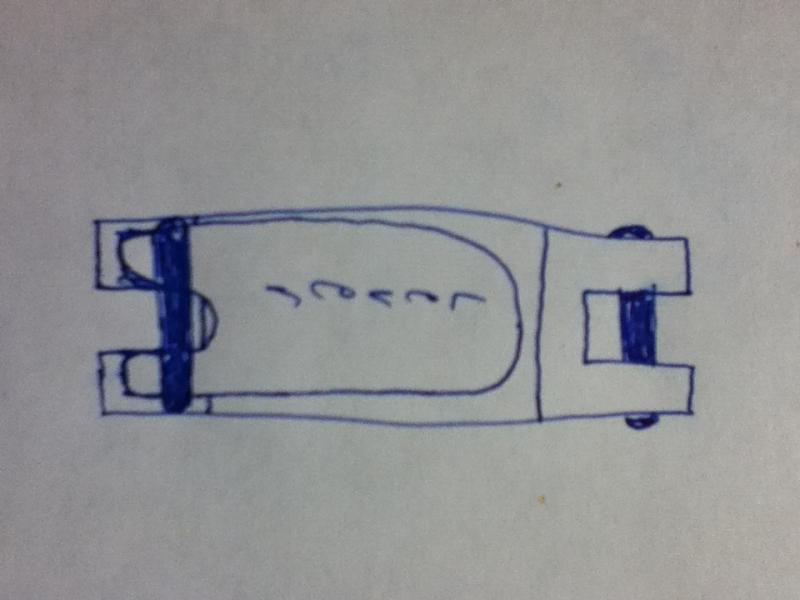

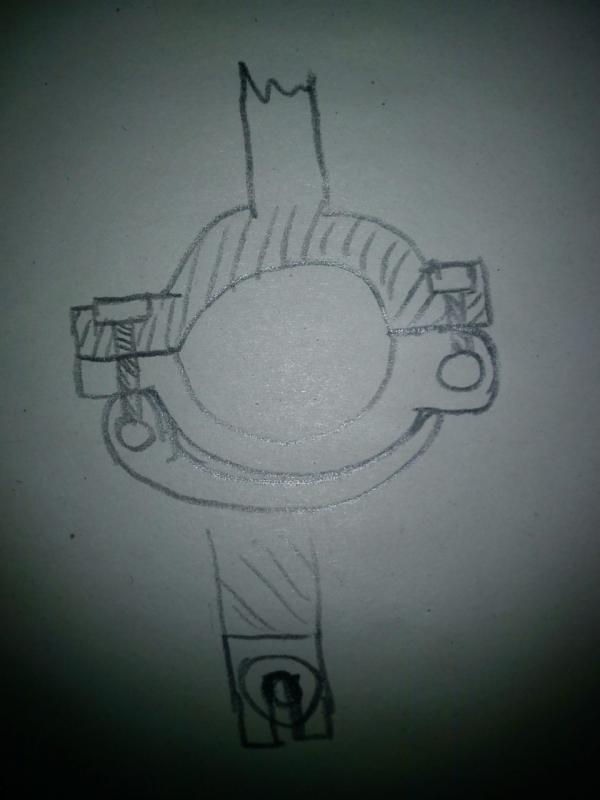

Sorry for my lack of description. What I meant was that you could use elements from both designs to create what you are talking about. Here are pictures to show what I mean.

The first image shows the whole thing clamped together. If you look at the side view, you can see a slot cut in the cap and the QR so that when you flip the lever, you can swing the cap away from the frame, and the screw can move through the slot in order to do this.

The second image is of the bottom of the cap, as it would be assembled and ready to ride.

The third image shows the cap as it would be to take the tire off. In order to get it off, flip and remove the lever, twist the screw 90 degrees to line up the pin with the channel, and the cap swings down.

Well I’ll give up with my drawings then - you’ve just drawn exactly what I was thinking of (I did initially have a different idea, but I think this is far better). The advantage of such a design on the bottom as you’ve identified is that you can size the parts much better than if you’re having to fit something through a specific hole size on the top.

The only refinement I’d make is for the screw to be a standard hex head bolt, with the cross piece slotting on to that with a hex cut into the top so that it can be used to turn the bolt - that allows you 1/6 turn adjustment of the bolt tension rather than the 1/2 turn adjustment if it is fixed on. Can still use the QR lever to adjust the bolt tension.

I don’t quite follow you, can you draw a picture of the bolt, and the way it would hook into the QR lever?

off the shelf solution?

I saw these and thought of you guys:

![IMG_1600[2].jpg](https://cdn.unicyclist.com/uploads/default/original/3X/f/6/f6b64f801ae28e843d72ba31cfaa0a835fe9a91c.jpeg)

![IMG_1617[1].jpg](https://cdn.unicyclist.com/uploads/default/original/3X/c/d/cdb8c43bfaa2815f05350c54e8404be8eae13a18.jpeg)

![IMG_1618[1].jpg](https://cdn.unicyclist.com/uploads/default/original/3X/2/0/20d216b087e1c7c003d8d24d9f6b9c58613d1bb3.jpeg)