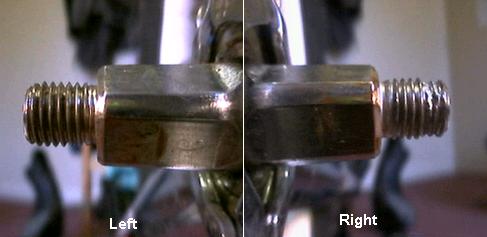

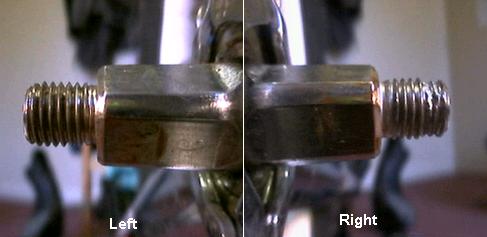

Spot the difference…

That puts paid to my saturday morning muni ride, anyway…

Phil, just me

Spot the difference…

That puts paid to my saturday morning muni ride, anyway…

Phil, just me

Harsh.

I see you had trouble with the threads on your suze too.

mine shattered so I recut the taper and tread.

'Twas quite strange; it was only on taking the things off that the problem became apparent. I had a go with 125mm cranks yesterday; they seemed to go on fine and straight, but then the nut wouldn’t come off easily this morning when I tried to put larger cranks on. Is it possible to overtighten crank nuts?

<think POSITIVE> Right, it’ll be a learning experience. I’ve never rebuilt a wheel before… still, I had been meaning to get round to stopping those spokes creaking…

Ho-hum.

Phil, just me, off to unicycle.uk.com again…

Well, it is. But it should be much harder than it is.

The trouble is that the threads have not been relieved ie. they are over hardened, therefore instead of stretching slightly (all bolts etc have greatest hold at some % stretch) the threads just snap off.

Ideally the square taper and centre hub would be hardened and the threads would not (or just a little)

I lack Joe’s technical knowledge, but as someone who changes his cranks more often than his socks, I’ve occasionally worried about this problem.

If the nuts (bolts on some hubs) aren’t tight enough, the crank works loose. if you over tighten them, you could strip the thread, or even ‘dink’ it completely. I guess that repeated tightening/undoing can’t be all that good for the thread.

My semi-eductated guess is that a better system would involve a longer thread with space for a locknut as well as the main nut. Then you could make the nut secure with less tension on the thread. Perhaps I’m wrong.

Anyway, thoroughly bad luck, Phil.

Or an opportunity to practise one footed riding?

I actually managed one-footed riding the other day, for the first time… I could idle, but not ride.

However… it’s the left* side that’s damaged, and that’s my best foot, so there goes that option out the window!

Phil, just me

[QUOTE]

Originally posted by phil

[B]

However… it’s the left* side that’s damaged, and that’s my best foot, so there goes that option out the window!

Phil, just me

[B]

Turn the seat round… or ride with your legs crossed:p

Ah, yes, of course… why didn’t I think of that earlier!

Phil, just me

ages ago when i was still riding a suzue hub it suffered the same fate,

roger sugested that i could cut the threaded section off, drill into the end of the axle and thread the hole to take a bolt, just like mtb bottom bracket axles,

i never tried it because i don’t have a bench drill to drill out the end of the axle, although i do have some taps lying arround.

i still have the old suzue hub and half a mind to try the above proceedure and use the hub to build a new wheel, maybee a 16" unicycle for work.

incedently i discovered that the threads were stripped when i was removing a bent set of cranks, when i realisaed the hub was a gonner i decided to get myself a splined hub.

however i discovered that the spare cheapo steel cranks i replaced the bent b.e cranks with actualy fitted without failing to tighten properly due to having less material between the bolt and the axle.

you won’t be able to do this.

Because the hub is hardened this is a no-go - you’ll be drilling domething as hard as the drill. You could re-temper the hub, drill it, and then have it hardened.

The ideal solution is a good quality tempered hub with an internal thread.

This internal thread allows you to use many more threads to take the load in the tightened bolt. On the current system there is only about 3, this is why the MTB bottom brackets are different.

They do seem a bit wasteful… the crank is right on the end of the axle which only extends about half way through anyway, and then the nuts usually only just manage to sit flush with the end of the bolt. Surely this is just asking to bend the axle if you’re only using the outermost 3/4 cm or so…?

As for splined hubs… not on the muni, unless it starts raining bundles of banknotes. But the trials uni… if the onza hubs do become available in the UK I might think about it.

Phil, just me

yeah - it’s tricky to mass produce within the tight tolerances required - if they are the painted steel cranks you’ll probably find paint inside the square of the crank which will compound the problem.

you know it’s cheaper to buy a whole onza uni for the hub than to buy a profile here in the uk!!

you could concievably atack you cranks with a large drill bit so that the nut tigtened on threads further down the axle, this would weaken the cranks a little, but probably not significantly.

Drill= round

Axle= square

?!!

you’d have to file out the square hole - or take a hand-grinder to the hub (as I did).

(don’t file the tempered hub - it’ll just blunt the file as it’s equally hard)

Either of these will be tricky but I’ve had no problems with mine since

youre absolutly right,

and i don’t have a blow torch either,

so i suppose i’m screwed.

i seem to remember that the qu-ax hub is like a mtb bottom bracket.

how exactly did you re cut the taper?

Is this a UK definition of relief? Thread relief in the US refers to a small groove less than the diameter of the stock (the thread stock in this case, not the axle) that gives the threads a place to terminate without running the die or a nut or the cutting tool on a lathe into the larger diameter stock, the axle here. Weld reliefs are a similar proposition where they give the molten metal a place to go and raise the welded surface slightly to reduce local thermal mass. It seems like what you are referring to is a heat treatment or tempering process which in the US we refer to as stress relief.

As for Phil’s threads, a cheapskate like me would try a triangular file, which has 60 degree angles like the thread angle, and carefully reshape the threads starting from the healthy, inside part and working out. Then a die or a hardened nut could be used to clean up the surfaces. I’m looking at a photo and it looks pretty bad but it might work. The downside is that you need those first couple of threads since you have so few anyway.

Sorry

I did mean stress relief rather than relieved. Or at least some form of re-tempering

If Phill’s hub is anything like mine then the treads were un-recoverable - and again you have the problem of trying to file a hardened surface, but then again, whatever is done will just be to recover the hub - so whatever works is acceptable

I’m not sure how successful this would be as there’s very little of the thread left at all for the last few turns; a lot of it seems to be thoroughly wedged in the nut, which has resisted repeated attacks to extract it.

Hopefully if it ever stops raining I’ll be off to a bike shop to get some replacement nuts, then attack the paint on the inside of the crank to see if I can get it on just far enough so the nut engages on the remaining thread.

On the plus side, I finally got round to adjusting some spokes on the thing, given that even if I went wrong I can’t ride it anyway right now. There are now no loose ones, they’re all about the same tension and the wheel is still straight, so maybe that’ll stop it creaking occasionally.

Phil, just me

Re: Potentially expensive

It is possible, the hardening on the hubs is nothing like that on a good

drill and tap. I have done this several times with out a problem and the

repair on one hub is still on going several years later.

Roger

----- Original Message -----

From: “JoeRowing” <JoeRowing.e84ta@timelimit.unicyclist.com>

Newsgroups: rec.sport.unicycling

To: <rsu@unicycling.org>

Sent: Saturday, November 16, 2002 6:37 PM

Subject: Re: Potentially expensive

>

> evilewan wrote:

> > *ages ago when i was still riding a suzue hub it suffered the same

> > fate,

> > roger sugested that i could cut the threaded section off, drill into

> > the end of the axle and thread the hole to take a bolt, just like mtb

> > bottom bracket axles,

> > *

>

>

> you won’t be able to do this.

> Because the hub is hardened this is a no-go - you’ll be drilling

> domething as hard as the drill. You could re-temper the hub, drill it,

> and then have it hardened.

> The ideal solution is a good quality tempered hub with an internal

> thread.

> This internal thread allows you to use many more threads to take the

> load in the tightened bolt. On the current system there is only about 3,

> this is why the MTB bottom brackets are different.

>

>

> –

> JoeRowing - Mad Man Muni - Custom Uni Engineer

>

> Joe

>

> Please visit pedal.me.uk for all your custom uni needs

> ------------------------------------------------------------------------

> JoeRowing’s Profile: http://www.unicyclist.com/profile/1544

> View this thread: http://www.unicyclist.com/thread/21694

>

>

> rec.sport.unicycling mailing list -

www.unicycling.org/mailman/listinfo/rsu

>

Re: Potentially expensive

On Sat, 16 Nov 2002 07:32:52 -0600, phil

<phil.e7qp0@timelimit.unicyclist.com> wrote:

>However… it’s the left* side that’s damaged, and that’s my best foot,

>so there goes that option out the window!

Reverse the seat and you can idle one-footed. From idling the pedal

shouldn’t come loose, or anyway “wrong side” shouldn’t matter.

Too bad about the damage though. When I change cranks (less often than

socks BTW, what would Mikefule’s socks smell like? :-)) I am always

wary about stripping the threads so I make sure that I hammer on the

cranks a lot before tightening the nuts.

The moon is drifting away from the Earth 4 cm a year!