Great job! Has anyone tried a similar solution on the Nimbus 29" with the rounded crown?

It should work just as well. My Nimbus 29 didn’t have brake bosses, so I used a DNA adaptor. The newer frames with the bosses should be easy enough to put a V brake on.

Do you guys also use a home-made solution for the other end? I mean to attach the brake lever to the saddle. Or maybe you all have a touring handle to attach the lever to.

My seat rail adapter has a post, or you could use something like this:

theres are avaliable and work well,i vse them my self on my muni and on my trials bike

The heatsink v adaptors are very nice, and as far as I have read they are the ones to beat, but to my knowledge they have been sold out for quite some time. TBH they are a bit overkill for a unicycle. If you need to put v’s on a bike they make more sense.

Yes, mine already has the magura bosses. The rim is aluminium anodised in blue, would this work fine with a V brake? I guess it would otherwise why would they sell it with the bosses installed… but as usual I found conflicting information on the web.

It should be just fine with a V. There seems to be an idea floating around that you need machined sidewalls to use a rim brake.

Rims never used to have machined sidewalls until super hard anodizing became the rage. The problem is that the hard anodizing was like braking on a chromed rim which squeals, and doesn’t brake very well. The solution was to machine the hard anodizing off of the rim.

With plain anodizing like what is on the Nimbus rim you won’t experience better braking with a machined sidewall. You might notice the seam as it passes the brake pads depending on how well aligned it is; however, that will go away in time as the rim wears.

Disc specific rims don’t have enough of a sidewall for the brake, but that doesn’t describe the Nimbus rim.

I think I got the same brake as uniShark. Is the return spring (the thin rod on the side) supposed to be under tension at all time? I install the whole thing and the brake works but doesn’t return properly. I see little screws for minor adjustments but they won’t go in far enough to fix the problem. Presumably, I will have to make my little hole for the pin at a different position, is that right? That’s a pain since I don’t have proper tools to drill through metal. From his pictures, it looks like uniShark had his little holes at about 45 degrees from the horizontal (and that’s about what I did).

Yes, the return spring is supposed to be under constant tension. On conventional brake mounts there are several holes adjust the major tension. If that doesn’t exist now, it probably should soon. The other option is to wedge something between the spring and where it contacts the brake arm, preloading the spring more. And yes, The screw is there to adjust minor spacing issues.

I actually ended up with two little holes on each of the brackets, in order to play with it to get the tension right. And yes, I agree they do need to be under tension.

As for drilling, if you’re using aluminum brackets, you can easily drill through with a hand drill and standard drill bit. Ask around with your neighbors and friends, and you’ll probably be able to find someone with a drill to just poke through a couple quick holes.

Thanks for your help guys. I managed to install my V brake last night and it seems to work fine. I haven’t had a chance to ride with the brake yet but I think my setup is strong enough to last. At the very least I will be able to try a brake on a unicycle for the first time without having to spend nearly the price of my whole unicycle just to see if I like it. I would probably have never tried that without this thread.

That was exactly my motivation as well. It would be a long, long time before I’d be willing to shell out for maggie’s (particularly new ones) just to see if I like brakes. I know used maggies can be reasonably affordable, but this still seems much less committed.

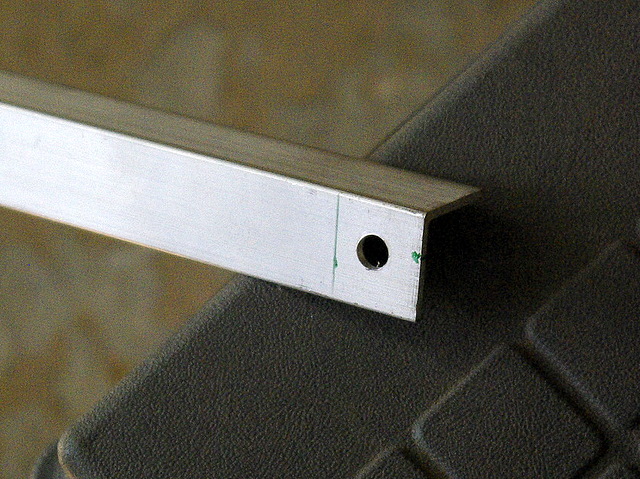

Photo’s to go with the first post

A while back the Gallery was dropped from this forum, and all of the photo’s on this thread (and many others) were lost. Here are the photo’s that were with the original post, and a few others at this link.

Bumpity bump bump. Great info for those who can’t justify spending $200 for maggies.

By the way how are your guys’s v brakes holding up if you still use them?

I’ve got about 6 months use on mine, and they work great. I used some XTR v-brakes left over from converting a MTB to disc; the nice thing about them is that the hardware they come with to make the parallel push mechanism work means you don’t have to fabricate any mounting plates for the uni.

Here’s a photo - you can see the brake booster I added to lock both ends of the mounting bolts in place. The Magura mount didn’t seem sturdy enough to support the bolt on its own, from the one end.

(The careful viewer will also spot my puppy’s paw wandering into view, as he comes to see what is up!)

Went to a friends house tonight. He hooked me up with some center-pulls:D:D:D We’ll see how it goes trying to put them on. I think the hardest part is gonna be mounting where the two wires meet. Have to have that little mount somewhere.

I hade made ones very similar to jtrops’ ones, using tape instead of the metal tube inserts. After a few months, it started degrading, and had to be re-setup frequently. I ordered the 4-bolt to v-brake adaptors from Tartybike, and it’s been perfect for over a year now.

I have these ( Google Image Result ) on my KH36 - they work great.