carbon is landfill and all just to save a few grams for his personal fun, disgusting.

Please don’t start that discussion. It’s to simplified just to say that carbon is bad for the environment. It’s also a waste to have 5 unicycles as I can only ride one at the time.

We are here to have fun and enjoy our hobby. If you want to discus ethics and the environment I don’t think this is the place.

Thanks for that breakdown. Back in 2019 I was the first person to own a 36-inch carbon rimmed 36er. That rim, made by Brauss, weighed about 580g. It was only available in 32h.

You are right, n+1 isn’t friendly to our planet either.

So let the following generations also have fun.

The only thing we should waste is our time with a hobby we have fun with, and the fun doesn’t need technical upgrades or new unicycles.

We have finally reduced cycling to one wheel.

ps: I don`t like aluminium either

The washers are for the hub end of the spoke not the rim end, and most people seem to say they are not necessary. I had a 36" wheel catastrophically fail and have been using them ever since, but have been using stainless steel instead of brass, and have recently got some brass ones. This is from Sheldon Brown’s wheelbuilding guide:

"Washers

[This section added by John Allen]

Flange thicknesses vary, but the spoke’s elbow should be snug against the flange. If it is not, the spoke’s tension will try to bend the spoke at the elbow – a frequent cause of spoke breakage.

You solve this problem by sliding a small washer onto each spoke before inserting it into the hub. Most spokes other than bladed spokes will accept a 2 mm (metric bolt size) or #2 (US bolt size) washer. Brass washers are best. These are not commonly available through bicycle parts suppliers, but they can be purchased over the Internet, for example at a hobby shop. Some hub/spoke combinations need two washers per spoke. Other combinations need washers only on the spokes that run from the inside of the flanges, or need two washers on inside spokes and one on outside spokes."

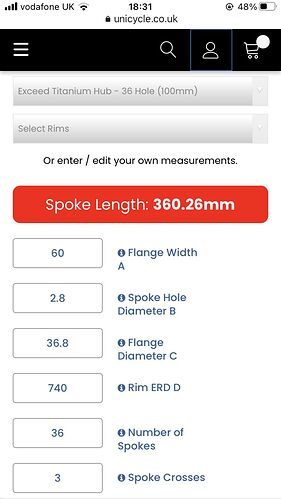

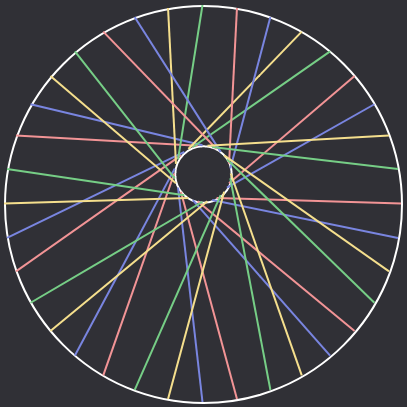

What length spokes shall I buy if I get an Exceed ti hub and want to lace 3 cross? I have a 36 hole 36" Nextie rim. I’m giving up on the idea of lacing it to my Schlumpf hub for now, it needs maintainance.

I have placed a brass washer between the hub and the spokes. My wheel builder said to do it on my last carbon wheel build. Nextie say you don’t need a washer where the nipple rests against the carbon fibre.

I use UDC for spoke length measurements and so far there have always been accurate but I do just double check just another spoke calculator website.

Mine just went from “building” to “sipping”! Can’t wait…

Washers on the hub why not, where do you get them? Just normal ones?

I believe you can get from UDC when you order the spokes. If not any good wheel building website.

Is anyone going to be lacing a Nextie 36" carbon rim to a qu-axle hub or an aluminum hub? Would be interesting to see a super duper ultra light set-up!

A number of them (including UDC UK) use identical javascript under the hood from here: http://petercermak.sweb.cz/WheelSpokesLengthCalculator.html

You can tell when a website is using the same code, because the figure will be identical. That calculator has a fudge factor of -0.2% to seemingly account for approximate spoke stretch under load, whereas other calculators that don’t have this will measure a fraction of a mm larger.

I know this because I hassled my brother to write me a calculator to figure out every spoke length for a unicycle wheel with an off-axis hub, and he went digging around all of the existing calculators:

Is this the kind of spoke failure that brass washers are good for?

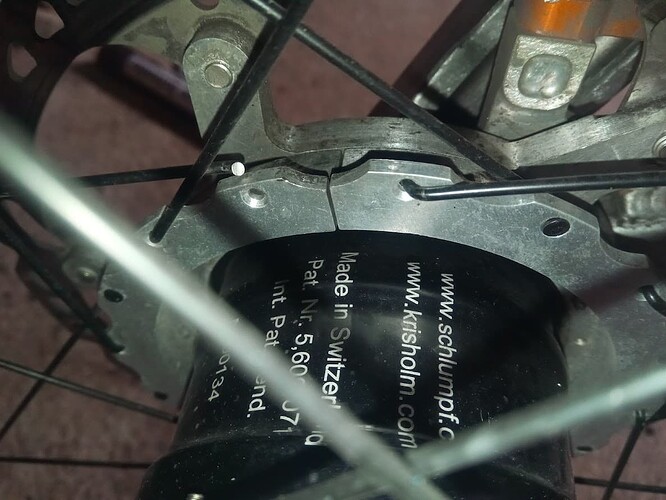

I’m a bit off topic, this happend monday on my G36 with a brauss carbon rim and the first prototype of the brakefast.

The spokes were tensioned hard between 110 and 120 kgf (24-25 on my parktool TM-1), fortunately the BF has nothing. I rode 1000 km before I had this failure.

Based on how bent the head of the spoke we can see on the right is I’d say yes (/maybe).

Based on the drawings I’ve seen, the Brakefast adapter is 3mm thick with 2.6mm holes which sounds close to the thickness where you shouldn’t need one/wouldn’t be able to fit one in though.

A sure way to decide though is when you loosen off one spoke so that it can move slightly in the flange, if it has side to side play (the head can move away from the flange) then washers would be a good idea.

I do note that it’s an outside spoke which has broken though which makes me wonder whether a levering force could also be a factor.

The Brakefast adapter is straight on both sides, whereas many hubs have at least the outside of the flange at an angle, so that the spoke does not rest on the flange much (if at all). If the spoke is resting on the outer “corner” of the flange then the force of it being pulled in to the centre of the rim could perhaps introduce a very large force pulling on the spoke head (and on one side of it as they’re not sitting flat).

I’d not expect it to be so much of an issue on a 36" wheel due to the small angle we’re talking about, but perhaps it is a contributing factor. The long side of the lever would after all be ~357mm and the short side of the lever being ~5mm, making the force theoretically ~71x larger (ignoring every other factor like spoke bending etc.).

Thank you for your explanations. I put the spoke back in place, I still have 3 spare spokes just in case… I took the opportunity to check the tensions of all the spokes.

On the same occasion, I noticed a bigger problem on the external splined bearing of the hub :

To be honest, I was expecting to see tyre blowing problems with this rim.

Of course, unicycle rims have always been designed to be wider than bicycle rims. This seems fine to me when it comes to off-road riding (low pressure), and we’ve seen the trend towards wider tyres for 2-wheelers.

Except that 36" is the size where speed freaks (like me) will want to reduce rolling resistance and unnecessary energy loss by inflating the tyre higher (3 bars and more).

I am not an engineer, but it seems to me that there are things to respect (rim width, tyre width and pressure) if you don’t want to take too much risk of tyre blowing.

Without going to the extreme of thin tyres like those on racing bikes (which I think would bring their own set of problems), a 25mm internal width rim (with hooks) would seem to me to be more appropriate for road use.

EDIT : The 36" brauss rim has an internal width of 28mm (without hooks), which already seems more appropriate for my road use.

By tyre hasn’t blown of the Nextie rim, it’s been on there since Friday 10th September.

It’s inflated at 35psi which is 2.4bar and so far no problems.

Nextie hooked rims, need a minimum order of 6 units. To be able to have hooked rims in 36” from them.

It is not a high pressure. On my 36" I run at 3 bar (45 psi) and some go to over 50 psi.

Nine years ago, I first had many problems with 29" rims with 40+mm internal width and slick tyres. I had less problems with my 36" wheels (I only had one heat related tyre blowing, the unicycle was left in a car in the sun).

This kind of problem usually doesn’t happen right away, but in my experience there are some contributing factors: rim too wide, pressure too high, heat, tyre wear (tyres that have already had a blow problem are damaged, even if you can’t see it), of course the absence of hooks on the rim…

I don’t think that 29" tubes are to blame, but some tube models are not suitable (the 29" tube has to increase its overall diameter when inflated empty 29=>36, otherwise it will deform too much). I use the reference given to me by @bouin-bouin (michelin butyl airstop 700x35-47, available in europe only?) and I never had any problem. Many people use tubes without paying attention to this. Most of the time, they have a lot of trouble with the fitting (risk of pinching the inner tube).