…Will be coming soon!

And at that time I’ll invite all others who have been inspired to make their own versions, like Jeremy, to post them here as well. Mike Penton of Uni magazine will be publishing my full article, (already submitted and confirmed) which will include in-depth details with many pics and a step by step of the entire build process, and where to find all the necessary parts for under $20!

It will document the genesis of my UCC, from first prototypes, to its current configuration. Also I will cover the braking system, tow-line attachment and use, how to make your own “hoop winder” and best of all, the fact that my system is light and portable enough to carry in your backpack, and set up 100% solo, in a snap!

I’ll also address some of the feedback and suggestions I’ve read, and why some may work, and some won’t, like using stakes when trees or other structures aren’t available; This was one of the FIRST ideas I had, and it was quickly scraped. My most recent innovation is an easy, efficient way to control the speed of the UCC, when it moves too fast because the terrain may be too steep, from one tree to the other. No, it’s not a mini-parachute, lol!

Stay tuned!

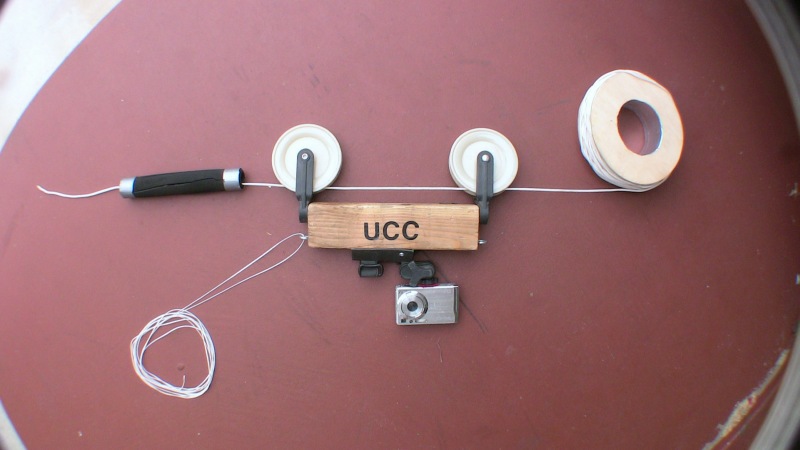

Ok here are a few pics of my current UCC with a new “brake” added! I modified a friction shifter and mounted a small wood dowel Perpendicular to the shifter handle.

It serves as both a brake, which can be adjusted upward to add tension to the cable, which slows it down if the angle or terrain is too steep, and also holds the rig in one spot, until you’re ready to go!

I just finished making latest and most efficient UCC line winder yet! The first winders I made are L-R in order from oldest to newest. I had originally made the center opening large enough for my hand and arm to go through for winding and letting out the line. This design greatly limited the amount of line that would fit on the winder.

The new winder is thinner by 1", and the diameter of the discs are about 1" greater than previous. The “hub” is dramatically smaller than the previous “arm hole” in the earlier versions. All these changes allow much more line on the winder. The hub is made from a 1" diameter piece of wood dowel, and after attaching it between the discs, and screwing them down to the hub at 4 points on each side, I then drilled a 3/8th" hole through the dowel at dead center.

This hole is used to insert a short phillips screwdriver, so the winder will spin freely on it while I’m reeling the line in, or feeding it out. It can also be used to stake the wider into the ground where it might otherwise roll away while I’m preparing some other part of the UCC. For quick winding, I installed a short piece of dowel on the outside of one of the discs, closest to the outer edge, and it also spins so when I’m winding the line in, it’s like reeling in a fishing reel!

Works like a charm and creates less “bulge” in my back pack since it’s thinner, and has a lower profile.

:D:)