Thanks for this @toutestbon, it’s helpful advice. I have found an earlier thing I need to sort out, as the only cleat-compatible shoes I have are an old Specialized pair with a crazy uncomfortable sole and no cushioning at all. So I’ll sell those and buy some modern mtb style clipless shoes (who am I trying to kid - I’ll one day eventually list the old shoes on ebay, but in the meantime I’ve already just bought some unused Five Ten Hellcats from a guy in Scotland, conveniently listed on ebay at a very good price, clearly just for me :-).

Once my two bargain purchases have both arrived I’ll start by putting the pedals on my regular around town 24" to get used to them, then hopefully move them across to the g26 ![]()

Well, the pedals have arrived and are in very good condition :-). However the pedal pins are about 3 times as long as I have used before, and could go in about twice as deep as the gap from my skin to my shin bone! Is it possible just to unscrew them half way (like one of them is already) or would I need to get a set of shorter ones?

You have a lot of threads available to allow you to unscrew them. However if you do that, you will need to fill the gap between the screw head and the pedal with an appropriately-sized washer. Then, tighten the screw so it won’t back out while riding.

That looks like a great pedal for unicycling, as it should force your foot into the exact same position on the pedal every time (I guess that depends on the shape and size of the metal plate on your shoes).

As far as I remember these screws are normally pretty tight (on the sets of Hope pedals I’ve put the pins into at least) and you can probably get away with not screwing them all the way in without putting anything under the head – with the proviso that you put thread lock on the screws. If you look at some of the screws in your pedals you’ll see blue thread lock (ie “Blue Loctite”) on some of them, that would have been on the screws when they were new.

There is one pin in your photo that isn’t all the way in – try it with an Allen key to see what it feels like – if it feels like there is a fair bit of resistance you should be okay not screwing them all the way home.

Maybe the cleats on these things mean that you need the pins sticking out a bit further though.

Sounds like a plan - thanks. I won’t know the cleat position and any requirement for longer pins until my recently bought shoes arrive (my previous clipless-compatible shoes have the right style of cleat fittings but are road shoes, and I had forgotten how completely useless for unicycling the tread on the bottom was).

There are two pins you can see at the back of the picture, the ones nearest the spindle, which are shorter than the majority of others, however the bunch of spares that came with these from the previous owner didn’t include any more of those shorter pins/bolts. I see that MagPed now do ‘Switch pins’ (DMR do a similar ‘flip pin’) which can be screwed in either way up, with one way giving you a short pin and the other a long pin - a good solution, but I’ll hopefully not have to stretch to buying anything else to get this to work, given that I have some blue Locktite knocking around.

All you need is a file…

…or you can go the Locktite route.

Or maybe you could screw the pins in the other way around. Good length, but maybe not aggressive enough. And a pain to unscrew if dirt ends up in the allen key hole.

Remember as well, that you can always make them shorter (but not longer) with a grinder ![]()

Our replies seem to have crossed in cyberspace… a file is more ‘measured’ solution than taking a grinder to them for sure ![]() I probably wouldn’t had the patience for that though.

I probably wouldn’t had the patience for that though.

Hehe. I wouldn‘t have the patience either, but I kinda liked the image of a guy filing 24 screws down ![]() . I think a grinder is the fastest way. A lathe with a grinding accessory (don‘t know the correct term) is probably the smoothest way.

. I think a grinder is the fastest way. A lathe with a grinding accessory (don‘t know the correct term) is probably the smoothest way.

That said, I would either buy shorter screws (reduces the weight!) or put a nut between the pedal and the head of each screw - that was by the way my solution for a set of pedals that I have on my 36er. It adds a bit of weight though.

These weigh a ton already so a few nuts won’t make that much difference - thanks for the idea (I was stuck trying to figure out suitable washers - nuts are the obvious solution)

Glad to have been able to give some reasonable input, for a change, before you went nuts.

However I still have another strategy planned to avoid that…

“Locktite Blue - saving you from going nuts, having a screw loose, and unpleasant shin-ow-nigans” ![]()

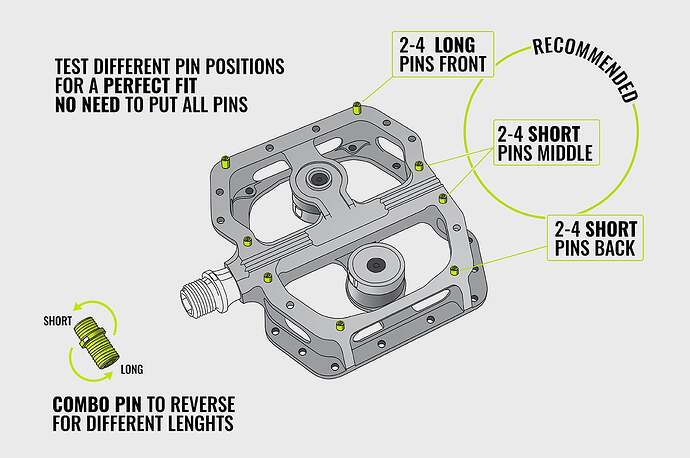

Didn’t you get several of the pins in 2 different lengths? I’ve installed the pins as recommended by Magped in the following drawing and I think it’s great:

My pedals are enduro2, yours may be the previous version?

Mine are the previous version without the clever reversible pins. I don’t know what pin selection came with the pedals when new, but what came in the box from the previous owner were 8 short pins already screwed in 2 per side per pedal, then just enough long pins to fill every other pin position on both sides of both pedals. I’m currently setting them up to have pins at the short length everywhere (mostly by only partially screwing in long pins), with the hope being that I’ll get a certain amount of twist possibility if the weight on the shoe rubber is well spread (Five Ten Stealth soles are pretty grippy on their own). I’ve not had time to finish that or test, but I’ll report back when done