thanks emile!

is this a kind of quick release bearing holder on the muni frame? that’s pretty cool!

i miss the mount for the disc brake…

edit: i like the look!

thanks emile!

is this a kind of quick release bearing holder on the muni frame? that’s pretty cool!

i miss the mount for the disc brake…

edit: i like the look!

Good point, it would be pretty hard to put a bolt on calliper mount on that.

Am I the only one who thinks this thing is pretty ugly and not in a ugly but functional way.

Thank you Emile.

The only thing that looks good about the frame is the quick release bearings and its shinyness.

I don’t get the square tubing and feel like the giant K1 star in the middle of it looks pretty bad.

I think the crown is ridiculous… The K-1 designs could be removed, then the crown could be lowered, it would then be lighter and it would probably looks better. It’s the same as an aluminum round crown (Gravity?) but higher with some crazy K-1 designs. I liked the old XTP better.

The bearing holders looks cool though.

I think the crown looks kind of cool, but it is a bit overkill in reinforcement, increasing weitght a tad and the crown could have been ~ 1 cm lower.

Box toobing is supposed to be stronger than round or oval for the weight. It can be pretty technical finding the ideal combination of dimentions of the box, wall thickness, sharpness/roundness of the corners. Honda (see below) used TONS of computer modeling to find this ideal which they never quite reached but made it better enough, considering their deadline.

I read about this in a motorcycle mag in an article about the new (for that year) Honda CBR 900RR, talking about the swingarm. I don’t remem the exact numbers, but it was significant, like 70% stiffer and 20% lighter.

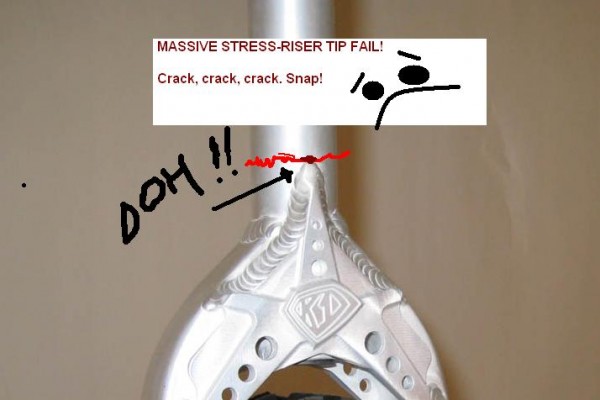

The top point of the star creates a MASSIVE STRESS RISER.

Fail. Simpler works better in this case.

So, where are you supposed to put your feet when coasting?

Same as usual, but it is less stable.

This style would be primarily for trials riders and those who don’t do foot on frame tricks and have issues w/ the frame hitting their knees w/ other styles.

if they make a frame like that for a 24inch i would get it.

I really dont like the idea of a quick release, looks like something to just get broken easier.

There are some CGI frames on the K1 facebook site :

I LOVE that street frame! if only it was long beak

hey boffo, you haven’t seen my frame yet

Am I the only one who thinks they are hideous?

I love my K1’s, but I think it looks pretty busy, and the welds look funky to me.

I loved my old Devil and original XTP. These new ones look a bit ‘overdone’ to be fair.

This new XTP isn’t too far off an Impact trials frame with a CNC’d plate just wacked on for good measure.

Bring back the old XTP one-piece CNC’d crown with some updates, that was a beautiful frame!

Since that reinforcer/logo thing tapers towards the top, wouldn’t that distribute the stress from below and not just transfer it like you are implying?:o At least it’s not a big mass all the way up to that point.

It wouldn’t be so bad if they didn’t weld up to the point but as it is that gusset or whatever you want to call it could work like a can opener on the seat tube.

Tubes especially if thinner and made of weaker/softer metal like alu and mag seem to suffer a lot from the stress of a weld being located anywhere past the edge of the tubing itself. This is quite a common failure on a lot of lighter weight trials frames, though it has happened a fair amount to even some ‘stronger’ frames:

The above example is one of the reasons why trials riders don’t really want traditional bashplates on 20" frames anymore. Especially the mount that is welded onto the downtube often causes a stress riser to form. Open ended gussets fare better than closed gussets, but do eventually fail too.

If anyone remembers the original XTP, it cracked at the crown weld where the seattube met. Then they released a V2 only a month or two after with an open-ended gusset welded onto the face of the bottom of the seattube. That helped a bit, but ultimately it only ended up postponing the crack instead of preventing it. The V2 of the original XTP just ended up having a crack at one of the top corners of the reinforcement gusset.

I would not be surprised at all if this newer XTP cracked at the tip of that plate from the stress riser formed. Unless that frame has ridiculously thick butting at that point of the tubing. Still, it’s gonna happen sooner or later given the forces that a uni frame’s neck has to go through in trials and street. Most of the time, simpler designs prevail.

I’m not against Koxx by any means. I’ve had A LOT of their components on my unis. It’d just be a shame to see such an expensive frame have such a catastrophic design fail.

It looks very heavy also!

Just do it no footed ![]() Pretty simple isn’t it? xD

Pretty simple isn’t it? xD