It’s just that the braking force runs through the gears with an external disc. If the disc is mounted to the hub shell the internals aren’t involved.

The problem is, the pedaling force also goes through the gears. Maybe we should switch to wheelwalking.

Do you belive that, unless you do big drops with the brake fully pulled, the breaking force is more likely to destroy the hub than your pedaling force? In contrast to pedaling, breaking forces are more constant.

I never understand why the inner shaft isn’t involved during breaking… the outer shell must be geared to the inner part or it will be freewheeling! So the axle will always be braked!. There are also cars with brakes on the differential instead of the wheel. So the most difference will be related to how the axle is braked: from one side or in the centre

Eric the only difference is one sided breaking to centered axle breaking. Maybe the craks will be more (hard) torsioning the axle, while the outer shell will brake the small gears. Don’t know if it more strong the hollow axle or the splitted energy trought those small gears

Yes but if you use the car comparison for a Schlumpf, then your car would have the disc brake on the gearbox, not on the wheel. So the braking would be different depending on which gear is engaged!

Pierrox, you are right. I just want to see the new adaptor tested. I just know that with that adapter it will 1) solve the disc brake disalignement during hard stuff involving cranks untightening 2) solve the broken axle issue.

I also know it will bring more complexity about: 3) wheel building and spoke tightenig

4) inner gear risk of brokening.

So I think it will need testing to decide if it will be a better solution or a worse one. I’m always happy about new ideas and solutions. It will improve and make unicycling science develop!

All the points have already been mentioned. I am not an engineer, but I have been using 2 schlumpf hubs almost daily for several years.

With an EDB I have had the cranks loosen several times, which resulted in the shifting shaft breaking twice. A priori, this kind of problem is related to the use of non-new cranks (for someone who has never changed cranks, the risk is minimal, and the latest version of the schlumpf hub corrects the problem with the possibility of using spacers).

Moreover, an EDB has 2 big drawbacks: 1/ it does not have the same power according to the speed engaged, and 2/ it is not possible to downshift while braking.

For these 3 reasons, I prefer a HS33 brake to an EDB (and I’m not the only one, there is at least Martin Charrier, he’s the one who convinced me).

I rode nearly 500km with Martin and Roger’s adapter on my G36, the test continues (Uh… here it’s complicated with containment, the test will resume as soon as possible), and a new prototype is in production.

When I set up my g26er with the KH EDB, I used blue thread locker not only on the axle bolts, but also on the cranks and axle splines to prevent loosening or inward creep, and it has worked successfully with no issues for hundreds of miles so far. Also there has been zero slipping if the knurled bearing due to the addition of a set screw which I tapped into the bottom center of the bearing cap.

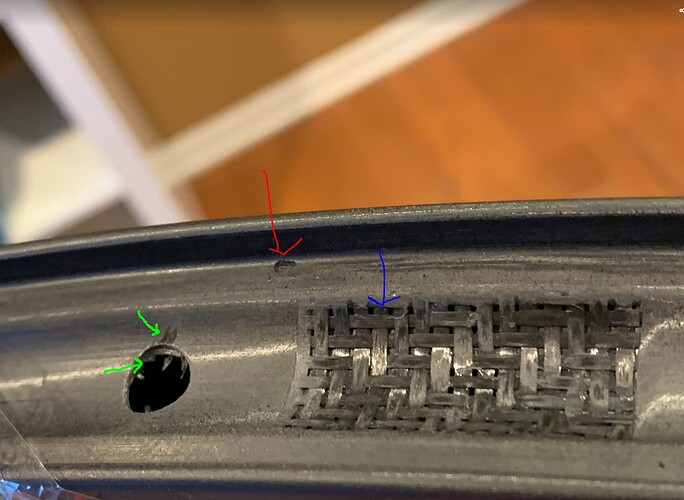

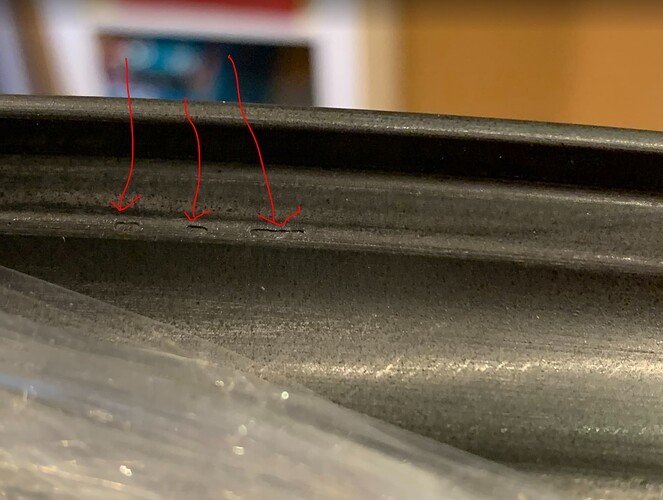

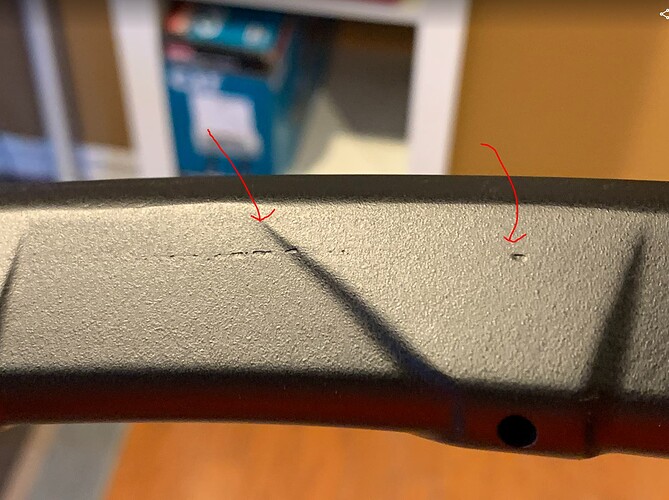

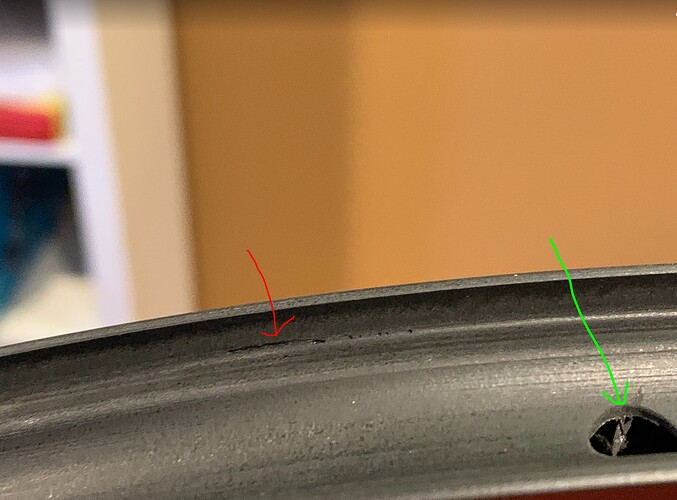

I just received a Braus rim and was wondering if other people’s rims had similar characteristics. If not, are these a concern?

- (red arrows) visible voids on the inner and outer surface

- (green arrows) tearing of carbon fiber near drill holes

- (blue arrow) an extra hole that is patched up on opposite side from the valve whole.

- A lot lighter than the spec (633 grams on UDC); mine weighs about 544 grams

I also wonder if (1) and (2) could partly be due to the rim being a lot lighter? (too lot epoxy resin?)

That looks horrible - definitely send it back!

How that passed QC is beyond me.

It doesn’t seem like you’re having much luck with parts at the moment!

As much as Nextie messed up big time with the “testing” of tyres, the rim I received from them is immaculate.

With how much this Brauss Alchemist rim costs, I’d definitely not accept less than perfection.

I don’t think this is the first time such issues have come up.

Not that I’m saying yours are OK. But it seems worse have happened and from my phones auto translate, while concerning to those in the thread - not classes as critical to the rim’s structure

Also this snippet from a review on UDC UK shows perhaps what you’re finding with the spoke hole:

Building was a nervous affair - there are a few rough edges to the carbon fibre spoke holes

I’d be certain to return that or want an explanation. The lower weight would have me worried it wasn’t the beefed up unicycle focused version.

I think we all had similar defects on the outside of the rim.

However, I hadn’t seen a patched hole like yours (blue arrow). I have a rim waiting to be mounted, I’ll check if there are any defects I didn’t see (I wasn’t very careful at the inspection, I was too much in a hurry to build the wheel).

If you’ve all had such defects, has anyone mentioned it and had a response from Alchemist?

These seem to me like seconds being sold off as premium products, especially in the case of this “repaired” rim where presumably an extra valve hole was drilled accidentally!

It doesn’t take much effort to remove the carbon swarf left behind, although perhaps they need to invest in better drill bits too if that’s an issue they’re having. Other manufacturers have no issues there.

It’s a curious external finish too - this is just an intentional mottling coming from the mould right, not some kind of truck bed type liner finish coat? It’s curiously random - not like any finish I’ve ever seen straight out of a mould before.

It has been mentioned after the first batch of rims arrived in France. Here is the response from TrueBikes, where we ordered the rims:

Hello Martin,

I found that only last batch of rims have these scratches. Also, my rims which are on stock.

I’m discussing this problem with manufacturer, they told me that it is extra layer for reinforcement, not scratches. The question is why it was not on previous batches of reinforcement rims…. I argued it is not possible that rim of that price looks like this!! I think they should change technological process to avoid this aesthetical problem.

Now they wanted to discuss it with owner of the form, company BRAUSS. This week the company is closed, next week the meeting will take place maybe and then we will see…

Question is if you use them or you want us to replace these rims… I don’t know if they will agree and if yes, how long does it take.

I’m also thinking what to do. I’m going to use these rims for my next project and they will be painted, so I use them probably.

I told them you want order another pieces but now you’re confused.

The rims must be in perfect quality!I’ll keep you posted…

Robert

I don’t think there has been any more messages after that one. We decided to keep the rims as that didn’t look to be a real issue.

It would be very interesting to know whether they’ve had any improvements in quality since that batch, or indeed if they’ve received any update from Alchemist/Brauss about the issues with that batch.

I argued it is not possible that rim of that price looks like this!

Exactly this, however looking at the price of their bike rims/wheels, the 36" rims do appear to be quite cheap in comparison!

As much as Nextie messed up big time with the “testing” of tyres, the rim I received from them is immaculate.

I’ve built a half dozen other chinese company’s carbon rims, and they also had “perfect” surface finishes

I don’t think this is the first time such issues have come up.

Not that I’m saying yours are OK. But it seems worse have happened and from my phones auto translate, while concerning to those in the thread - not classes as critical to the rim’s structure

It seems that they said external scratch on that rim may have been due to a pedal that was loose in the box. Mine shipped with spokes taped to the center of my box, and was packaged super well! So I don’t think shipping damage is likely.

I think we all had similar defects on the outside of the rim.

However, I hadn’t seen a patched hole like yours (blue arrow). I have a rim waiting to be mounted, I’ll check if there are any defects I didn’t see (I wasn’t very careful at the inspection, I was too much in a hurry to build the wheel).

Interesting that many people had similar defects on the outside.

I see on one of your google photos, there is a rectangular looking patch:

We were looking for an explanation, but there is no certainty that it is the pedal.

And for my picture, it seems indeed that this defect is in the same place as the patch on your rim.

I agree with you, there are many defects on the rim that I don’t find on my two 29" LB rims.

The Nextie rim probably has less small defects, but it has a bigger one. There is still room for improvement.

In English the major Nextie problem would probably not be defined as a defect. It was designed and constructed as intended by Nextie.

The issue just lies in that it’s been designed for a hypothetical tyre that doesn’t exist, and that the company lied about their testing, and how well it works with a Nightrider.

But the long and short of it is that as of right now, all 36er rims have some downsides and it’s very much an enthusiasts game working out what you’re prepared to deal with, which is a shame. Room for improvement is one way of putting it.

Brauss/Alchemist- smaller width, but 32h and Presta only, more expensive, and seemingly poor quality control.

Nextie - larger width, more drilling and aesthetic options, and cheaper, but doesn’t work with current tyres at higher pressures (at least without modification).

The fact that many other riders have used the Brauss rim without issues yet gives me some confidence. I’m waiting to hear back for an explanation of all the spots I pointed out. I also have a handful of Light Bicycle rims on my unicycles/bikes that haven’t given me any problems yet!

I had thought the patch was for removing the bladder during manufacturing, as my hole is quite big and rectangular. However, your photo looks like a patch covering up a small circular hole which makes me question my initial guess. Light Bicycle says they use the valve hole to remove the bladder, but a separate hole is used for other name brand rims as well:

https://forum.slowtwitch.com/forum/Slowtwitch_Forums_C1/Triathlon_Forum_F1/Enve_Wheel_Repair_P4729749/

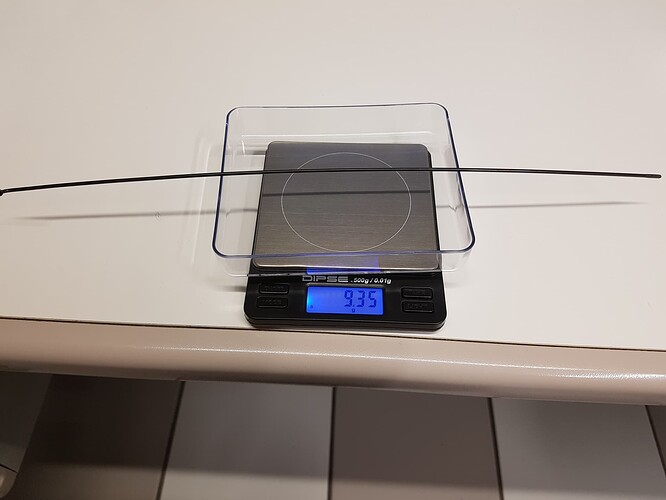

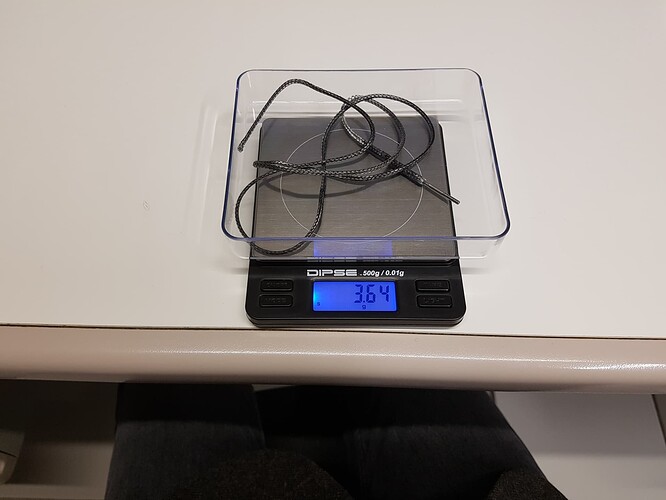

I am experimenting various solutions right now amd it seems that using rope spokes on a 36er we can get about 200gr rotational mass less.

So using: a carbon rim, a tubeless setup, ropes used of spokes… we can achieve an incredible wheel, maybe using 110-117 cranks I’ll avoid using a geared hub for road+XC. When I’ll get everything done I’ll post more