I’ve seen your modified brake lever but it won’t work on my G36. The brake lever should measure at least 50 cm and couldn’t be straight because of the shape of the KH T-bar.

That’s all about your will, tools and time. I just used a shorter iron squared bar, but was easy to cut and get the shape using the required tools. Longer and more bended shapes can be achieved (if you look at your lever you can easily guess how and wherea it was pressed, cutted and bent)

Translation: that’s about 207 off and 414 kPa on the road.

Take a look at the Shimano GRX inline levers ( BL-RX812). I’ve yet to give them a try, but that should enable you to have a lever in both positions with a single disk.

I fancy doing it for my freewheel so I can have a lever on both sides of my t-bar in an easy to reach position (I hate the central mounting setup).

Looks great! How do you mount it? Do you simply put a duct - is this the right name for the part having the oil in it? - on both sides of this lever?

I have been looking for something llike this but never ffound before.

Yeah, the lever installs inline:

As it’s designed to mount on the wide section of bars (31.8mm) it may well need some serious (off-centre) shimming to mount nicely on bar ends (22.2mm) but I doubt it’d be too much of an issue.

It may well be that the metal strap clamp could just be re-drilled to be shorter.

On all of the pictures I’ve seen it’s also looked like it was out at a bit of a weird angle, but the specs say that it has reach adjustment.

I created a new thread for this discussion: Shimano GRX inline (secondary) brake lever (BL-RX812)

Why do you say that an EDB can cause damage to the Schlumof hub? I’ve been using one on mine (#428) with no issues whatsoever.

I could imagine doing some damage if braking during a shift, but otherwise I wouldn’t worry about it.

It’s just that the braking force runs through the gears with an external disc. If the disc is mounted to the hub shell the internals aren’t involved.

The problem is, the pedaling force also goes through the gears. Maybe we should switch to wheelwalking.

Do you belive that, unless you do big drops with the brake fully pulled, the breaking force is more likely to destroy the hub than your pedaling force? In contrast to pedaling, breaking forces are more constant.

I never understand why the inner shaft isn’t involved during breaking… the outer shell must be geared to the inner part or it will be freewheeling! So the axle will always be braked!. There are also cars with brakes on the differential instead of the wheel. So the most difference will be related to how the axle is braked: from one side or in the centre

Eric the only difference is one sided breaking to centered axle breaking. Maybe the craks will be more (hard) torsioning the axle, while the outer shell will brake the small gears. Don’t know if it more strong the hollow axle or the splitted energy trought those small gears

Yes but if you use the car comparison for a Schlumpf, then your car would have the disc brake on the gearbox, not on the wheel. So the braking would be different depending on which gear is engaged!

Pierrox, you are right. I just want to see the new adaptor tested. I just know that with that adapter it will 1) solve the disc brake disalignement during hard stuff involving cranks untightening 2) solve the broken axle issue.

I also know it will bring more complexity about: 3) wheel building and spoke tightenig

4) inner gear risk of brokening.

So I think it will need testing to decide if it will be a better solution or a worse one. I’m always happy about new ideas and solutions. It will improve and make unicycling science develop!

All the points have already been mentioned. I am not an engineer, but I have been using 2 schlumpf hubs almost daily for several years.

With an EDB I have had the cranks loosen several times, which resulted in the shifting shaft breaking twice. A priori, this kind of problem is related to the use of non-new cranks (for someone who has never changed cranks, the risk is minimal, and the latest version of the schlumpf hub corrects the problem with the possibility of using spacers).

Moreover, an EDB has 2 big drawbacks: 1/ it does not have the same power according to the speed engaged, and 2/ it is not possible to downshift while braking.

For these 3 reasons, I prefer a HS33 brake to an EDB (and I’m not the only one, there is at least Martin Charrier, he’s the one who convinced me).

I rode nearly 500km with Martin and Roger’s adapter on my G36, the test continues (Uh… here it’s complicated with containment, the test will resume as soon as possible), and a new prototype is in production.

When I set up my g26er with the KH EDB, I used blue thread locker not only on the axle bolts, but also on the cranks and axle splines to prevent loosening or inward creep, and it has worked successfully with no issues for hundreds of miles so far. Also there has been zero slipping if the knurled bearing due to the addition of a set screw which I tapped into the bottom center of the bearing cap.

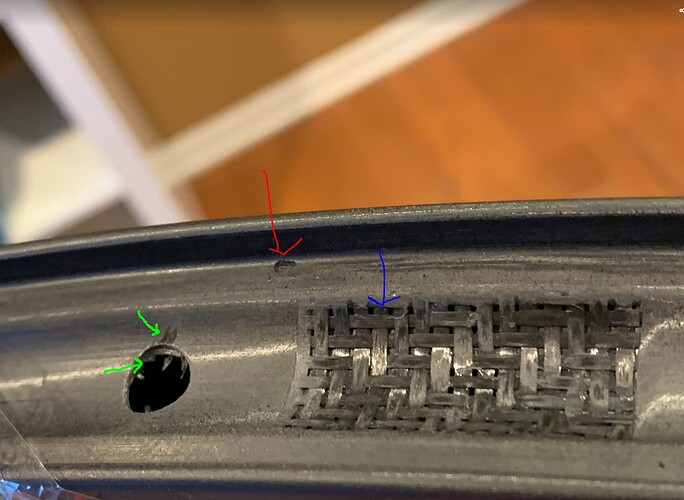

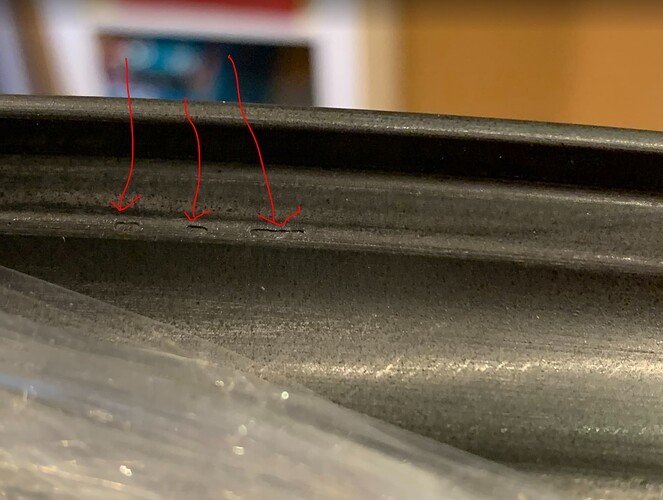

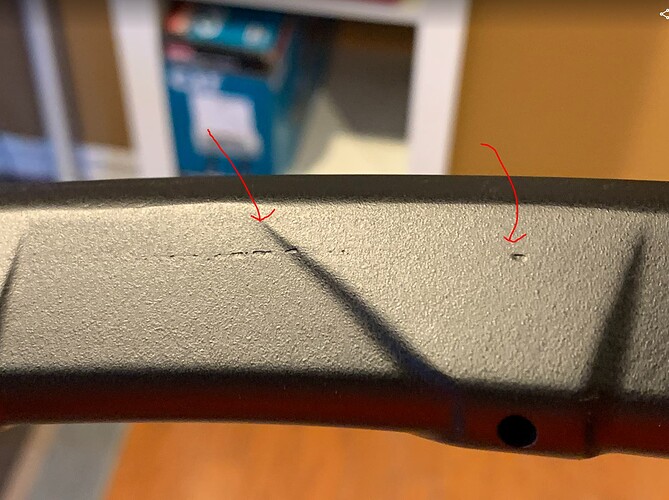

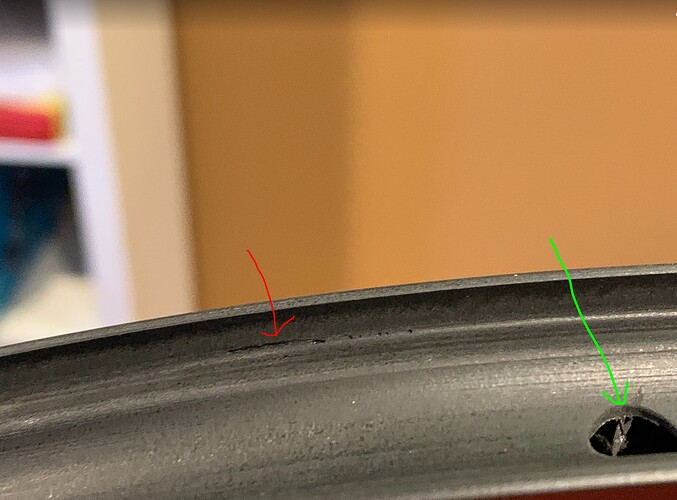

I just received a Braus rim and was wondering if other people’s rims had similar characteristics. If not, are these a concern?

- (red arrows) visible voids on the inner and outer surface

- (green arrows) tearing of carbon fiber near drill holes

- (blue arrow) an extra hole that is patched up on opposite side from the valve whole.

- A lot lighter than the spec (633 grams on UDC); mine weighs about 544 grams

I also wonder if (1) and (2) could partly be due to the rim being a lot lighter? (too lot epoxy resin?)

That looks horrible - definitely send it back!

How that passed QC is beyond me.

It doesn’t seem like you’re having much luck with parts at the moment!

As much as Nextie messed up big time with the “testing” of tyres, the rim I received from them is immaculate.

With how much this Brauss Alchemist rim costs, I’d definitely not accept less than perfection.

I don’t think this is the first time such issues have come up.

Not that I’m saying yours are OK. But it seems worse have happened and from my phones auto translate, while concerning to those in the thread - not classes as critical to the rim’s structure

Also this snippet from a review on UDC UK shows perhaps what you’re finding with the spoke hole:

Building was a nervous affair - there are a few rough edges to the carbon fibre spoke holes

I’d be certain to return that or want an explanation. The lower weight would have me worried it wasn’t the beefed up unicycle focused version.