I’m new to the site and only a beginner, but I love the tech and development work people are putting in. The idea of using a CVT makes brilliant sense and I would love one. Is it not possible to machine a new ramp plate as a test and case harden it? Wish I had more time and access to machines…

It would be in principle, I just got the feeling that the precisions and tolerances of any of the parts in the Nuvinci hub are well beyond what I’d be able to do in my own shop. There are many surfaces that all need to contact simultaneously, and the flatness of the back plate has to be just perfect. I think it would probably be easier to use some kind of precision grinder and modify the existing ramp plate to slope equally on both sides rather than making a new one from scratch

I think we all wish we had more time!

Justin

More riders

An’So, Angelo, and Andrew all from Vancouver, as well as Noli from Seattle, all got a chance to ride it last week while claiming only one new victim.

For some reason the cranks are making a lot of creaking sounds now, and I haven’t yet gotten around to moving the shifter onto a pair of small handlebars. As a result the 3spd guni is still at our shop and hasn’t been shipped down to Madison for all you attending the NUACC to try.

If I get creaking and shifter repositioning done this weekend, then there’s a chance we could ship it out on Monday and have it available at least for the final few days of the convention. Is there much interest in me doing this?

Justin

Justin, if ramps are equally on both sides, it means that in the center of the ramps, there is no traction possible ? Don’t you think this is not an issue ?

IMO if the tolerances are close enough you will get very little slop and the moment you have movement it will engage. I know I’m not Justin, sorry for chipping in ![]()

I have a Nuvinci on my cargo bike, and so I think I can answer this. You need to have at least a little bit of a dead spot in order for the transmission to shift. When there is even a little load on the balls the traction fluid grabs, and doesn’t allow a shift. Letting up on the pedal pressure lets the hub shift. I think you could make the dead spot very small, and it would still function well, but for this you may need to make a new ring. What about two rings set back to back so that the ramps are facing opposite directions. That way you could in theory adjust the dead spot to be the smallest possible.

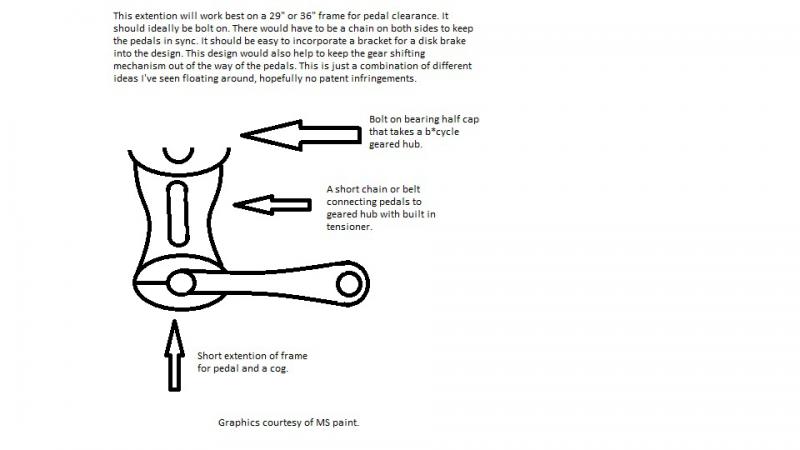

If I understand what you are showing you have the wheel built with the geared hub and a chain going to a crank set below it. In this orientation you would need to have a way to time the right and left cranks so that they stayed at 180 degrees to each other since the spindle couldn’t go through the wheel.

You are right, that is one of the challenges to this idea. I have never played with any off the shelf parts, so I wouldn’t know what is practical.![]()

Wow, this is an extremely exciting thread!

I’m very interested to see this come out of the prototype phase (or even when it comes time for a second prototype).

Fantastic work!

Why can’t you have the cranks mounted on a spindle that spins free through the hub body, has a spindle mounted or crank mounted sprocket on one side and a hub mounted sprocket on the other side? Maybe that makes the bearing situation a little odd, but it solves the timing issues since the crank arms are connected.

I realize there’s no off the shelf stuff for some of these ideas, but for someone with the knowledge and “machines” ![]()

My Sclumpf arrives next week.

That sounds like a workable idea, depending on material strength. I really need to make friends with some machine shop owners ![]()

Enjoy your Sclumpf Nurse Ben ![]()

Argh I know it is off topic but it is Schlumpf not Sclumpf! So much precision went into making it at least get the name right ![]()

Sch like the start of school- with a shhh sound,

lum is a long lum/loom kind of sound,

and pf is the ending with the oompf sound.

Schlumpf! There are not many vowels among all those consonants.

Sorry about that! Awesome idea with the 3 speed, it will be interesting to see how far it goes. Lets see just how complex we can make the simple one wheeler!

No gears, No handlebars, No brakes, No problems is the unicycling motto of the past! ![]()

That’s pretty much what Justin made for his jackshaft build. It would be great if you could put a spindle through a Nuvinci hub and have a small transfer box to get the torque from the spindle to the hub.

I don’t think it would be easy to make that work though. The axle in the Nuvinci is stepped and tapered, and as I understand it they had to redesign the hub in order to get the nuts on both sides to be the same. So the axle shape seems to be integral to the design of the mechanism.

I’ve never taken my Nuvinci apart, so maybe Justin can shed some light on this.

[QUOTE=Schlumpf! There are not many vowels among all those consonants.

[/QUOTE]

I was to lazy to go and check the spelling, thanks for the laugh though :D:p

For a guy who doesn’t wear a helmet, you sure are particular about spelling, you sure you haven’t been hitting your head too much… ![]()

Clearly there is no disrespect intended, just as when my name is regularly misspelled/mispronounced by my patients, it’s not personal, it’s just a name, it’s not who you are…not to mention, I’m pretty sure I say it correctly ![]()

Now back to our scheduled program…

And one more thing:

WEAR A HELMET!

who messes up ben ??

Clearly not moi ![]()

I like lemons, they make great baseballs, but they are pretty much juiced after one hit.

So, who’s ridden the 3 speed and lived to tell the tale? Any feedback?

I can see som great road applications, putting a “transmission” in between the stays on a Nimbus Shadow styled frame, three speeds could become five speeds, yes?

So what’s the reality of making something like the Alfino 11sp into a locked hub, i.e no freewheel?

I did a quick write up and posted a video a page back

It’s not that challenging to ride, but it does seem to rack up the injuries.

If a locking reverse freewheel can be built into a chain driven unicycle hub (which I doubt is easy but is no doubt possible) then any standard hub could be used - might be a bit odd having 1:1 reverse but any random gear forwards ![]()