Andrew, the bearing holders on your frame look fine, except for one thing:

Make SURE they have retaining lips on each side. If you can’t get them on each side, then make the retaining lip on the outside. This is really important. I have ridden frames without these libs, and when powering up hill the frame will slide off the bearing.

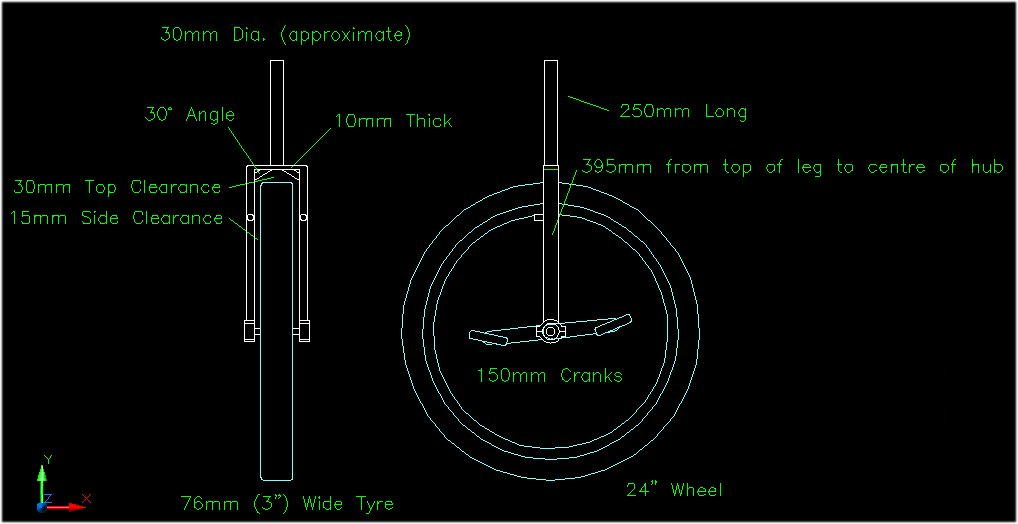

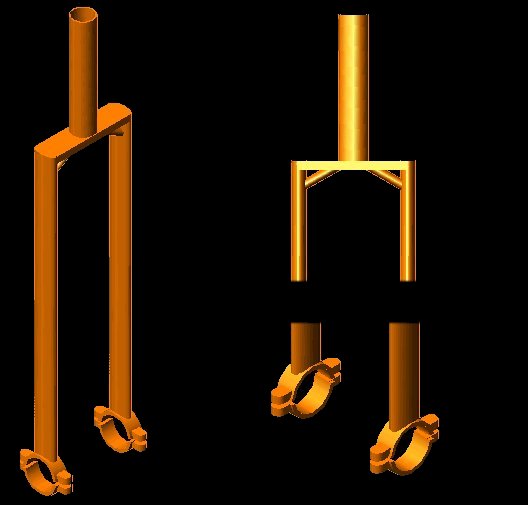

The 10mm thick steel plate for the top of the crown is excessive. I would reccomend around 3-4mm. even better, try 2.5mm with a gusset that goes all the way under the crown (instead of triangles on the sides), like on the 2004 KH model.

As for the fork legs, just borrow a KH frame and take the specs off that.

Miyata seatposts suck. I’ve bent one, and that’s enough for me. Get a thomson and a rail adapter if you care about your unicycle. As for diameter, go with 27.2mm ideally. If not, 25.4 is a good size. Whatever you do, avoid 22.2mm. It’s a uselessly small size.

You define the thickness of the tube’s walls as “wall thickness”. Thus, internal diameter (ID) + 2(wall thickness) = outside diameter. This applies to ovalized tubing aswell.

I’ve been trying to use metric for your sake, but when it comes to wall thicknesses, i can’t do that. I don’t have a conception for a fraction of a millimeter, so you’ll want a calculator for this part. 1 inch = 25.399mm, but you can round to 25.4mm. So, anyways, i’d use a 0.065" wall thickness, although you could go with a bit less, maybe 0.055, but I wouldn’t go less. You don’t want too thin walls because the frame will be as easy to dent as a soda can,regardless of its strength.

If you go with a 27.2mm ID seattube, you could go with 0.050" wall thickness, at least. I wouldn’t go less, for the reasons highlited above.

Another reason to go with a lardger dia. seatpost/seattube is because it will mean a larger surface area to be welded to the crown, which will mean more stiffness, something to be concerned about in this crown design (because this crown has a very thin attachment plane for the seattube).

One last thing to note: You can do this with trig, or just play around with it. The flange for the top of the crown (that 10mm thick plate you called out) must be long enough (front-back) that when it is tilted forward at a 30* angle, the seattube will fit on the top of it, with some room to weld. if it’s too short, the seattube will run off the edge, and be ugly. The same goes for the plate and the forklegs. What I’m getting at is the specs of these parts are more interconnected than they seem.

make it black

make it black  .

.