What do you people think is the ideal amount of clearance between the tyre and inside of the fork leg for muni? What about trials?

Thanks,

Andrew

What do you people think is the ideal amount of clearance between the tyre and inside of the fork leg for muni? What about trials?

Thanks,

Andrew

I think that for muni, if you have enough clearance that mud and rocks don’t get stuck in your frame, you OK. My muni doesn’t have much clearance. Stones ping off the inside of the frame a lot. The tire never rubs the frame when climbing though, so it’s good enough for me.

Mojoe

I definately agree with that, but how much clearance would you say that is? 5mm?

Andrew

Andrew,

A frame builder I know suggested starting with 3/8 of an inch on either side to start. I think that’s @9.5mm.

Thanks Rod. So with a 72mm wide tyre and a set distance between the bearings, how do you get this much clearance? I’m just thinking about the GP Unicycles frame. Gary received the prototype frames and I don’t think they have enough clearance.

Andrew

Andrew, there’s people out there that know way more than I do. I just scrape the iceberg, but here’s my two cents. I hope you get more help.

I can’t remember if you found the Chris Reeder frame pages. He dimpled in the fork blades to make up for the problem of having a wider tire and a narrower hub. I followed suit, as seen in the blue frame.

Chris used less side clearance than 3/8". The link for technical statistics is below this next picture and includes other pix.

Chris Reeder isn’t around in the uni world any more, as far as I know. He moved on to other interests, but contributed a lot while he was here.

Thanks again Rod. I had the legs of my custom frame crimped to add clearance, but not as much as yours. How could Chris possibly stray from the unicycling world? How much clearance is there on that blue muni of yours?

Thanks,

Andrew

My KH24 muni frame has about 5mm of clearance on each side of a Gazz 24x3 tire.

If you’re going to have minimal side clearance make sure the frame is stiff enough that it’s not going to flex and rub the tire. If it’s a flexy frame you’ll need more side clearance. The KH frame is very stiff so 5mm of side clearance seems to work just fine and I’ve never had the tire rub the frame.

Thanks John.

If anyone’s got the time (and only if you’ve got a Gazz 3" or something of the same width), could you please tell me how much clearance you’ve got, what brand the muni is, and whether or not you’re satisfied with that amount?

Thanks a lot,

Andrew

andrew_carter

If anyone’s got the time (and only if you’ve got a Gazz 3" or something of the same width), could you please tell me how much clearance you’ve got, what brand the muni is, and whether or not you’re satisfied with that amount?

Mine’s a 24x3 Nimbus with 28" non flat top frame- tyre is a 3" Halo Contra.

I’m shocked to discover that the side clearance between the knobbles and frame is only 2 or 3 mm.

Having said that I’ve had no problems at all with it, not done much mud riding though.

I don’t know what the best way to measure clearance is, I used a tape measure.

Thanks for that Dave.

Everyone,

The prototype GP muni frames have 3mm clearance with a tyre that is actually bigger than the Gazz 3". With a Gazz there’ll be about 3.5mm or so. Is this enough or do we have to get crimping? There is negligible flex in the frame. The design is really starting to grow on me (but I still prefer mine of course :)).

Andrew

I have the time, and using my impaired judgement I would say I have about 1cm either side between the knobbles on the 3" wide Gazzaloddi and the Wilder 6160 frame. I am not sure if it is exactly 10mm but it is definitely more than a 3mm gap. I am totally satisfied with the clearance, the only time debris have been caught there is due to the long seatpost sticking down close to the tire. Perhaps it is 3/8 of an inch.

Andrew, here is more of my two cents. If I were to be working on a prototype, I would build one with the straight forks and one with the crimped forkes, and then see which one performs better.

Crimping is difficult to do to make sure it is matched up on both sides if it is done by hand. In mass production, I am sure it could be done, but I don’t think that’s where your going with this project.

In my frame, we crimped and bent the fork legs at the same spot to make get around the Gazz 3.0 and then meet the Suzue hub. When I look closely at my frame, the dimples are a bit off. The left side dimple is a hair down from the right side. Also, there is some frame flex, probably caused by the dimpling, but i minimized that by putting shims on the side of the bearings within the main cap bearing housings.

I had the frame crimped in order to budget in possible frame flex. It was a wise decision from my stand point, because I did get frame flex when climbing. I could see tire rub marks on the inside of the fork legs even with over 3/8" clearance on the side.

Mud side clearance.

If you can make a wheel that is tough and won’t go out of true too easily, then I think you can go with the narrow clearance like less than 5mm. I think the clearance on the Nimbus frames/Yuni is pretty tight, but I don’t hear people complaining about that. I haven’t heard any concern for twigs or rocks getting stuck between the fork blades and the tire, with some tight clearances. My main concern would be riding on the trail and the rim went out of true. But you don’t hear about that.

I put a height clearance on my MUni of about 1 inch for mud clearance, mainly based on a lack of experience. The few times I have ridden in the mud, it never got that close, it only filled up the spaces between the lugs, outwardly appearing like a slick. The mud on the side wasn’t too much. So that top clearance was too high, I should have done half that.

Note: I rode in some mud once, that was like glue. It just stuck to the wheel and then congealed on the tire and in that huge gap at the top and side of the tire to the point of being impossible to ride. I think this type of mud is rare and even with the wide clearances on my MUni, the mud locked up the tire in the frame.

So, in a nutshell, IMHO, try different clearances and several or at least two prototypes to see what works. Mud side clearance doesn’t seem to be a big factor for most people, seems to me, based on the lack of concerns posted at RSU.

I have only been riding for two years and dabbled in the frame creation game with little experience. So, take my advice knowing that there is not many years behind it.

Good luck - I envy that creating feeling when developing a new MUni. It’s really fun and frustrating at times as you know. Keep up the great work.

Stay sharp.

If you’re getting 3/8" worth of wheel wobble, either your wheel is really out of true or badly built, or your bearing holders are off centre, or your frame / bearing holders really are incredibly badly made & wobbly, much more than my Nimbus II/Yuni frame anyway. Are you sure the shimming is okay?

I’ve got about 5 mm on my Pashley and it’s only been a problem once, when I rode in clay mud for 4 hours and I had to stop and throw the mud off. However that was stopping pretty much everyone on bikes as well as the munis and I reckon is too rare a situation to bother designing for.

Joe

Thanks a lot for all your help Rod. I do appreciate it. Joe, thanks.

I’m still interested in how much clearance other munis have.

Thanks,

Andrew

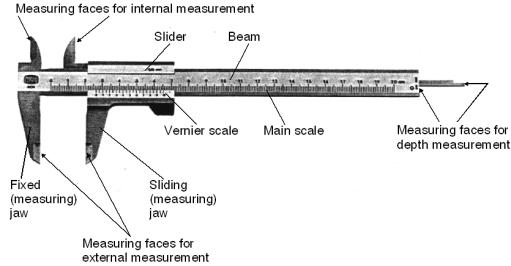

I used a cheap vernier calliper that has a depth guage.

Here is a picture of a vernier calliper that shows the depth guage at the end. I got the image from this page <http://www.qfm.uni-erlangen.de/gps/content/Chapters/ch23/>. The page even has an animation that shows how to read a vernier calliper. A Google search will find other sites with instructions on how to read a vernier calliper.

The picture is a high quality calliper compared to mine. Mine was less than $15 and does not look like a high precision measuring instrument, but it works good enough for me to measure seatposts and such.

Andrew,

If you don’t get what you need try a search or start one of your polls, again.

Good luck.

Stay sharp.

I don’t quite remember how to use one of those but my dad has one and they are very very accurate.

Does anyone have any experienceon crimping frames. I think it could be done with a hydraulic press. I tought that I’d plant my unis frame on about 1"-3" wide iron bar and then put a 5"-8" wide iron plate above the frame push down with the plate. The tubing should only bend on the 1" side which would be the inner side of the frame. You could control the amount of crimping with iron bars of desired thickness. These would ensure the same amount of crimping on both sides. I’m planning to do this to my Nimbus/Yuni if it doesn’t have enough clearance with my Gazza. The Nimbus II frame should have about 3-4mm, but if it’s not enough… crimp, crack, OH SHIT! WHAT HAVE I DONE!

I had my muni frame made by a framebiulder and he crimped it. I didn’t see how it was done or anything but I haven’t had any problems with strength or anything like that.

Andrew